Vacuum stirring barrel capable of stirring in double directions

A vacuum stirring and two-way stirring technology, which is applied to mixers with rotating stirring devices, mixer accessories, dissolving, etc., can solve problems such as uneven stirring and poor dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

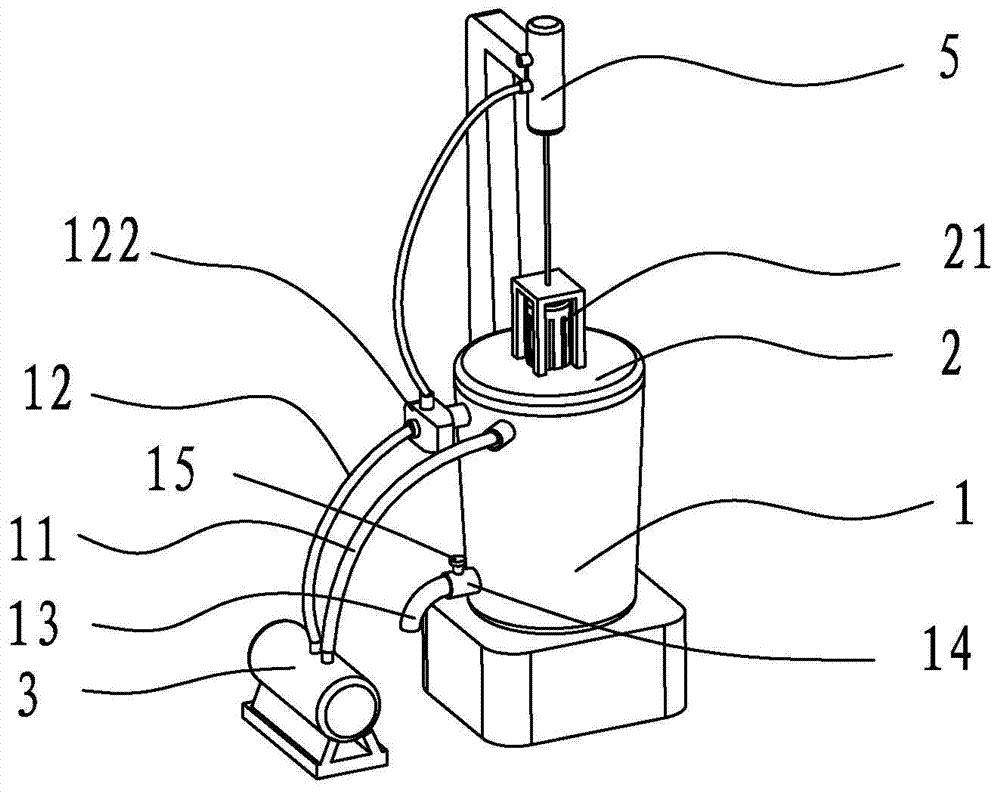

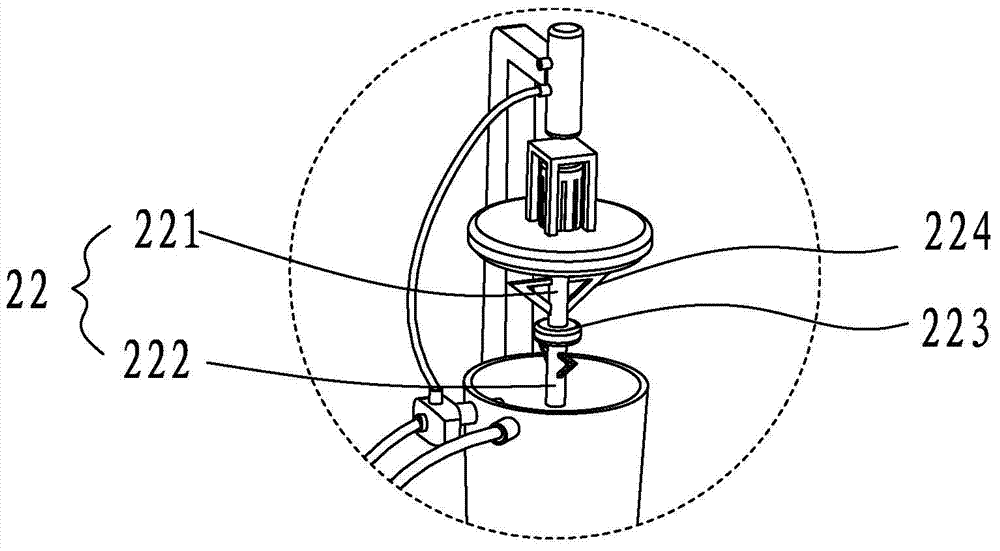

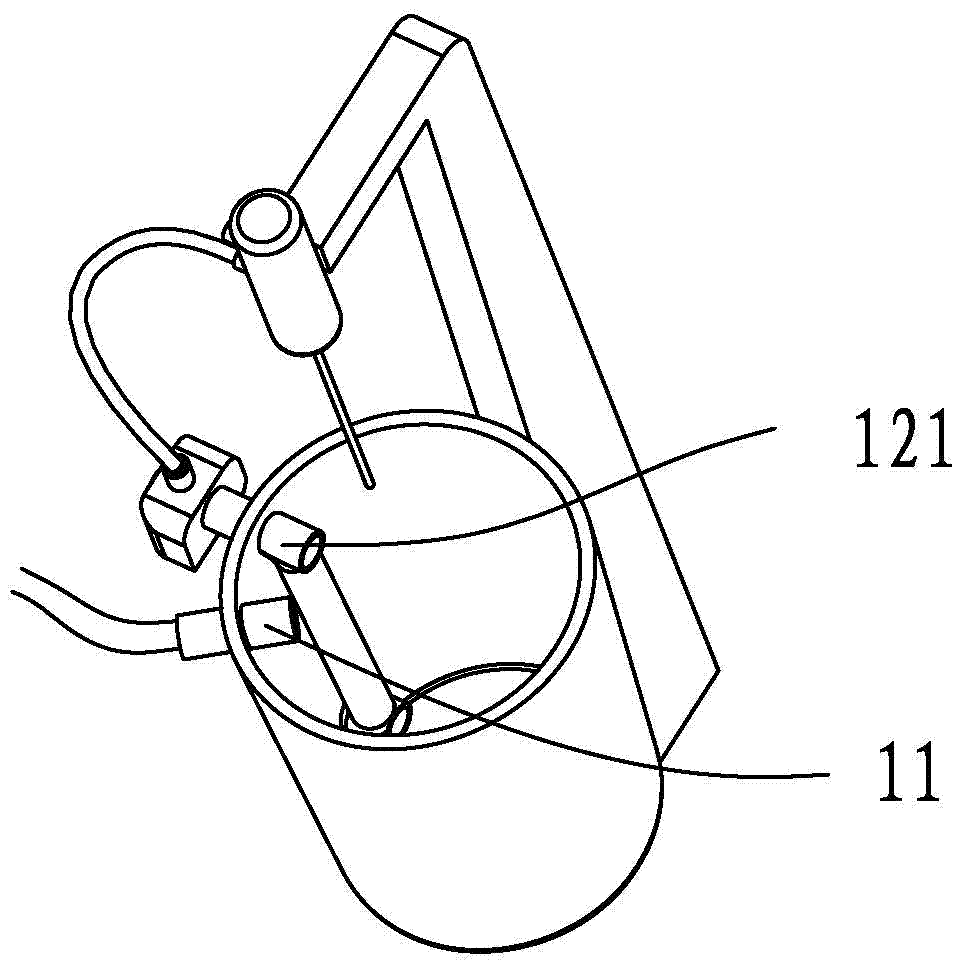

[0015] Such as Figure 1 to Figure 3 As shown, a two-way stirring vacuum mixing tank includes a mixing tank 1, the bottom of the mixing tank is a base, a top cover 2 is arranged on the top of the mixing tank, and a sealing strip is fixed on the bottom of the top cover at the edge of the mixing tank. A motor 21 is arranged on the top of the cover, and a motor bracket is fixed outside the motor. A pneumatic cylinder 5 for lifting the upper cover is suspended above the motor bracket. A stirring rod 22 is arranged at the bottom of the upper cover, and the stirring rod is driven by the motor to rotate. The side wall is provided with a suction pipe 11 and an air intake pipe 12. The suction pipe is used to remove the air in the mixing tank so that the material is in a vacuum environment when stirring. The air intake pipe is used to re-inject air into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com