Preparation equipment of antirust agent for electric power engineering construction

A technology of electric power engineering and anti-rust agent, applied in chemical/physical process, dissolution, mixer, etc., can solve the problem of not being able to rotate, stir and prepare in multiple directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

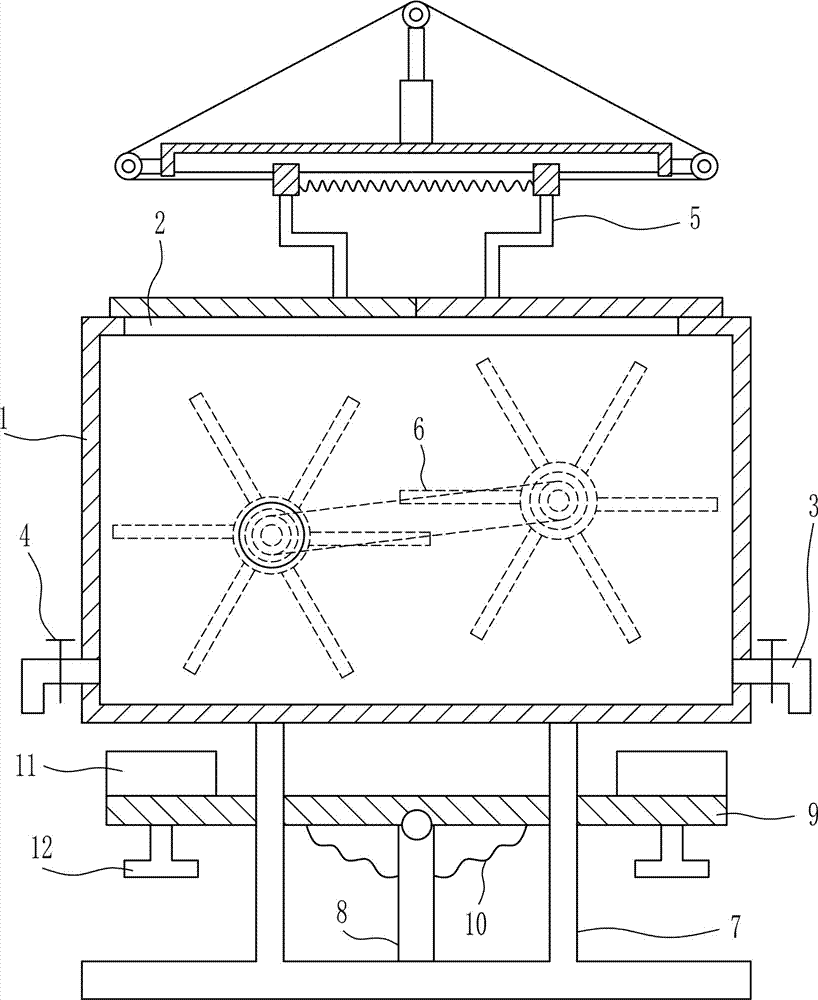

[0037] A kind of antirust preparation equipment for electric power engineering construction, such as Figure 1-7 As shown, it includes a preparation box 1, a liquid outlet pipe 3, a valve 4, a switch mechanism 5 and a preparation mechanism 6, the top wall of the preparation box 1 has a through hole 2, and the lower parts of the left and right sides of the preparation box 1 are connected with a liquid outlet pipe 3 , The outlet pipe 3 is provided with a valve 4, the preparation box 1 is provided with a preparation mechanism 6, and a switch mechanism 5 is provided directly above the preparation box 1.

Embodiment 2

[0039] A kind of antirust preparation equipment for electric power engineering construction, such as Figure 1-7 As shown, it includes a preparation box 1, a liquid outlet pipe 3, a valve 4, a switch mechanism 5 and a preparation mechanism 6, the top wall of the preparation box 1 has a through hole 2, and the lower parts of the left and right sides of the preparation box 1 are connected with a liquid outlet pipe 3 , The outlet pipe 3 is provided with a valve 4, the preparation box 1 is provided with a preparation mechanism 6, and a switch mechanism 5 is provided directly above the preparation box 1.

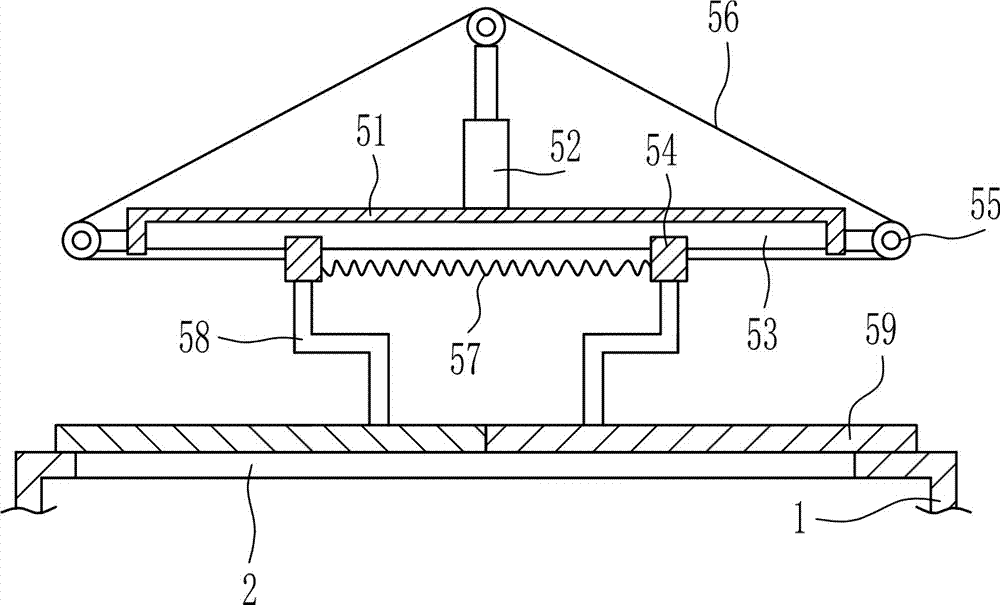

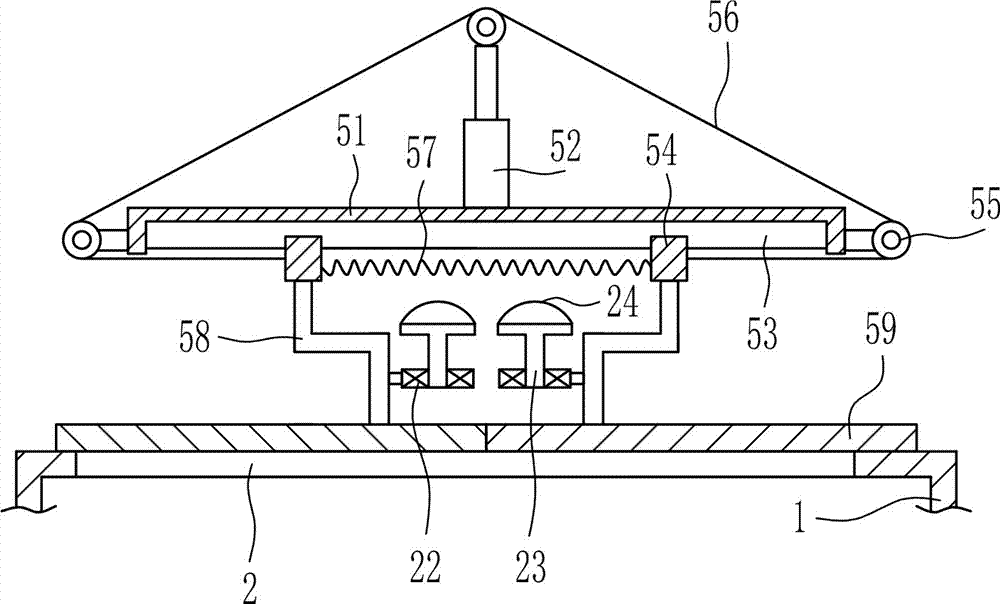

[0040] The switch mechanism 5 includes a mounting frame 51, an electric push rod 52, a slide rail 53, a slide block 54, a guide wheel 55, a stay cord 56, a first spring 57, a first connecting rod 58 and a baffle plate 59. An installation frame 51 is arranged above, and a slide rail 53 is connected to the top of the installation frame 51, and a slide block 54 is slidably connected...

Embodiment 3

[0042] A kind of antirust preparation equipment for electric power engineering construction, such as Figure 1-7 As shown, it includes a preparation box 1, a liquid outlet pipe 3, a valve 4, a switch mechanism 5 and a preparation mechanism 6, the top wall of the preparation box 1 has a through hole 2, and the lower parts of the left and right sides of the preparation box 1 are connected with a liquid outlet pipe 3 , The outlet pipe 3 is provided with a valve 4, the preparation box 1 is provided with a preparation mechanism 6, and a switch mechanism 5 is provided directly above the preparation box 1.

[0043] The switch mechanism 5 includes a mounting frame 51, an electric push rod 52, a slide rail 53, a slide block 54, a guide wheel 55, a stay cord 56, a first spring 57, a first connecting rod 58 and a baffle plate 59. An installation frame 51 is arranged above, and a slide rail 53 is connected to the top of the installation frame 51, and a slide block 54 is slidably connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com