Demounting and recycling device for abandoned streetlamp shell

A technology for recycling equipment and shells, which is applied in the field of dismantling and recycling equipment for waste street lamp shells, and can solve the problems of multi-stage dismantling of street lamp shells that cannot be discarded

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

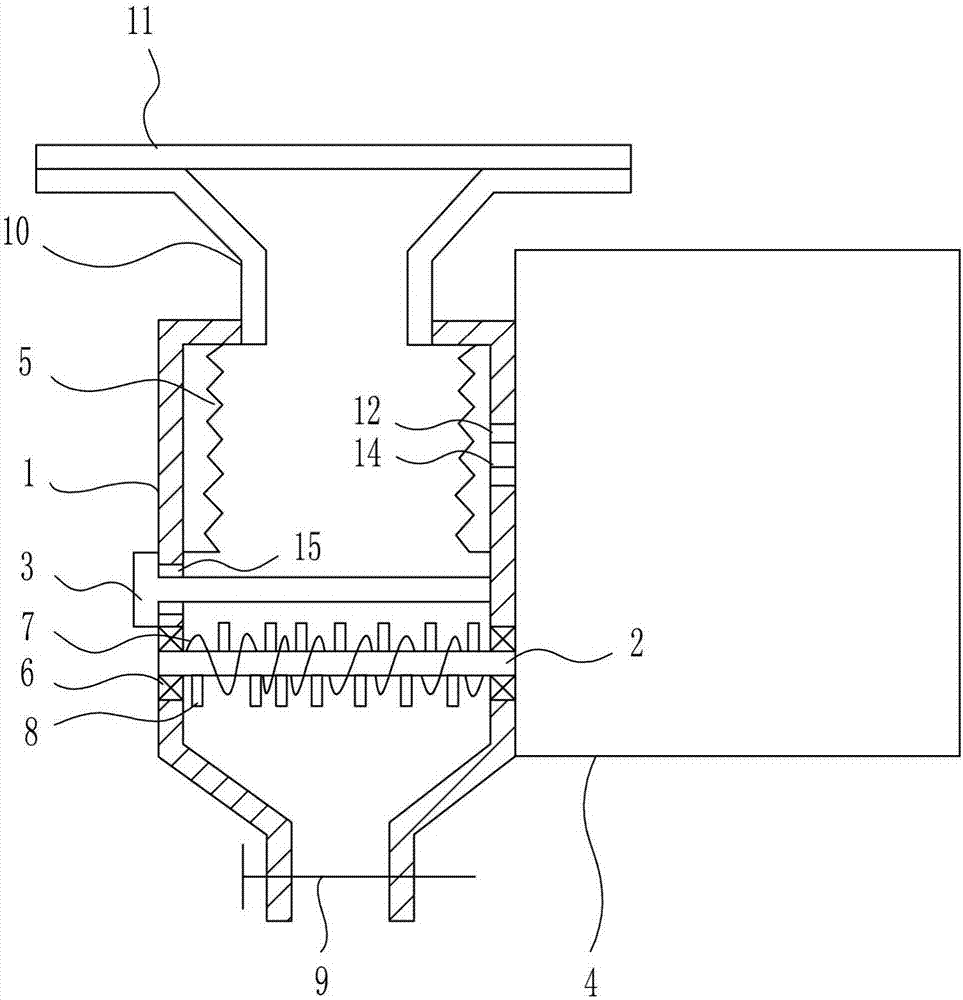

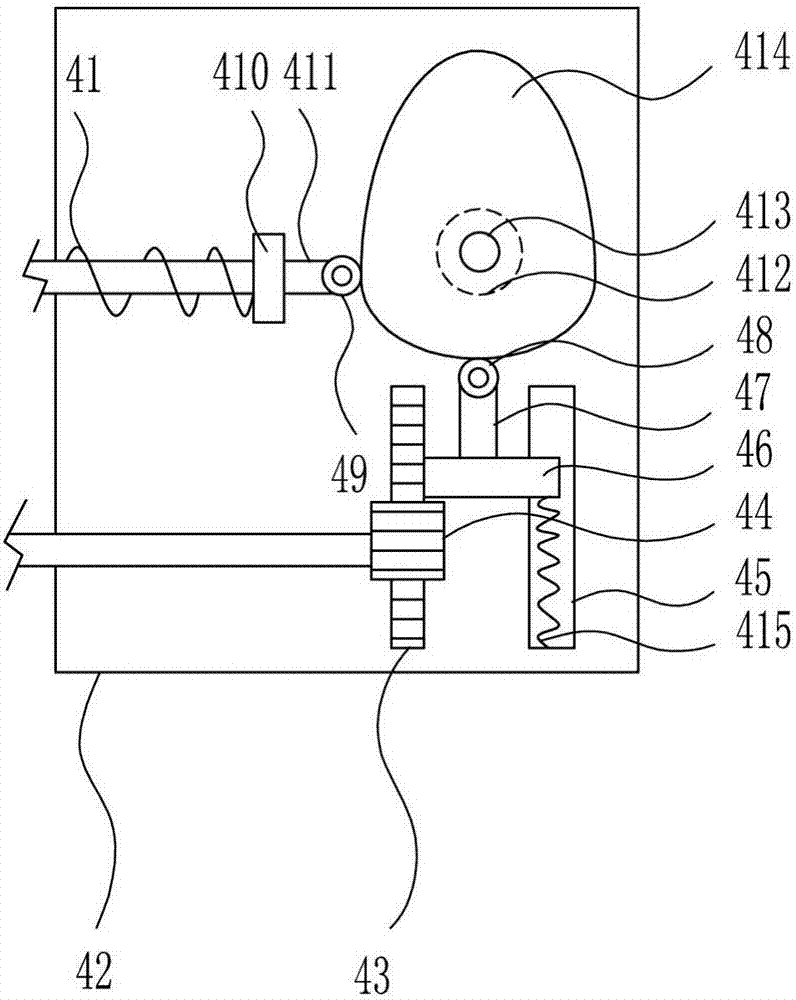

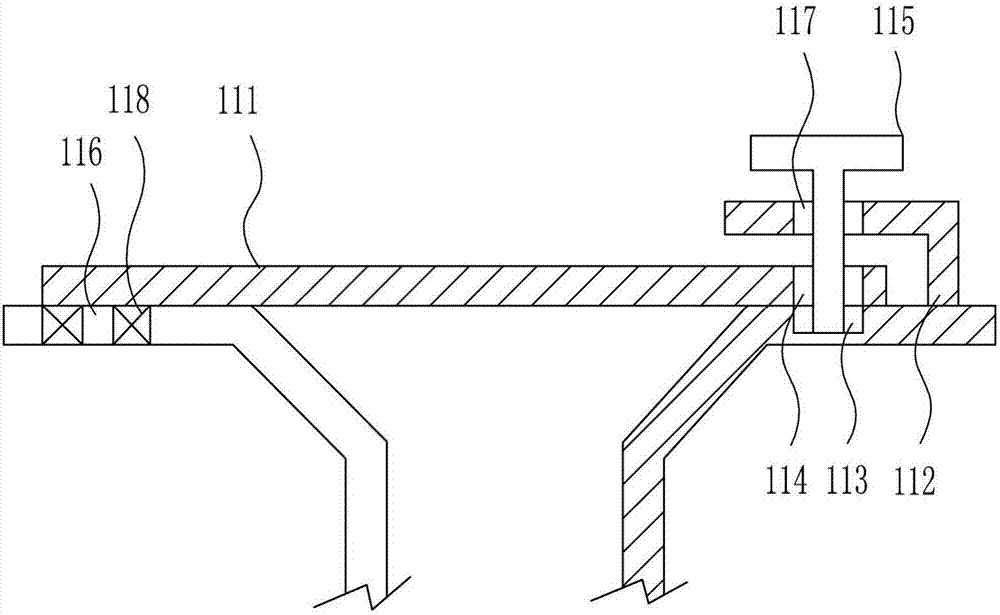

[0030] A dismantling and recycling equipment for discarded street lamp shells, such as Figure 1-5 As shown, it includes a crushing box 1, a first rotating rod 2, a first baffle plate 3, a driving mechanism 4, a crushing tooth 5, a first bearing seat 6, a screw 7, a crushing knife 8, a valve 9, a feed hopper 10, The switch mechanism 11, the moving rod 14 and the crushing mechanism 13, the top center of the crushing box 1 is connected with the feeding hopper 10, the top of the feeding hopper 10 is connected with the switching mechanism 11, and the inner wall of the crushing box 1 is symmetrically connected with the crushing teeth 5 There is a first small hole 12 above the right wall of the crushing box 1. A moving rod 14 is connected in the first small hole 12. The moving rod 14 passes through the first small hole 12. The left end of the moving rod 14 is connected to the crushing teeth on the right side. 5 connection, the middle part of the left wall of the crushing box 1 has a...

Embodiment 2

[0032] A dismantling and recycling equipment for discarded street lamp shells, such as Figure 1-5 As shown, it includes a crushing box 1, a first rotating rod 2, a first baffle plate 3, a driving mechanism 4, a crushing tooth 5, a first bearing seat 6, a screw 7, a crushing knife 8, a valve 9, a feed hopper 10, The switch mechanism 11, the moving rod 14 and the crushing mechanism 13, the top center of the crushing box 1 is connected with the feeding hopper 10, the top of the feeding hopper 10 is connected with the switching mechanism 11, and the inner wall of the crushing box 1 is symmetrically connected with the crushing teeth 5 There is a first small hole 12 above the right wall of the crushing box 1. A moving rod 14 is connected in the first small hole 12. The moving rod 14 passes through the first small hole 12. The left end of the moving rod 14 is connected to the crushing teeth on the right side. 5 connection, the middle part of the left wall of the crushing box 1 has a...

Embodiment 3

[0035] A dismantling and recycling equipment for discarded street lamp shells, such as Figure 1-5 As shown, it includes a crushing box 1, a first rotating rod 2, a first baffle plate 3, a driving mechanism 4, a crushing tooth 5, a first bearing seat 6, a screw 7, a crushing knife 8, a valve 9, a feed hopper 10, The switch mechanism 11, the moving rod 14 and the crushing mechanism 13, the top center of the crushing box 1 is connected with the feeding hopper 10, the top of the feeding hopper 10 is connected with the switching mechanism 11, and the inner wall of the crushing box 1 is symmetrically connected with the crushing teeth 5 There is a first small hole 12 above the right wall of the crushing box 1. A moving rod 14 is connected in the first small hole 12. The moving rod 14 passes through the first small hole 12. The left end of the moving rod 14 is connected to the crushing teeth on the right side. 5 connection, the middle part of the left wall of the crushing box 1 has a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com