Environment protection dust collection equipment used in workshop

A dust removal equipment and environmental protection technology, applied in the directions of dispersed particle separation, chemical instruments and methods, combined devices, etc., can solve the problems of limited application scope, large volume, complex structure of dust removal equipment, etc., and achieve the effect of accelerating the time of dust deposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

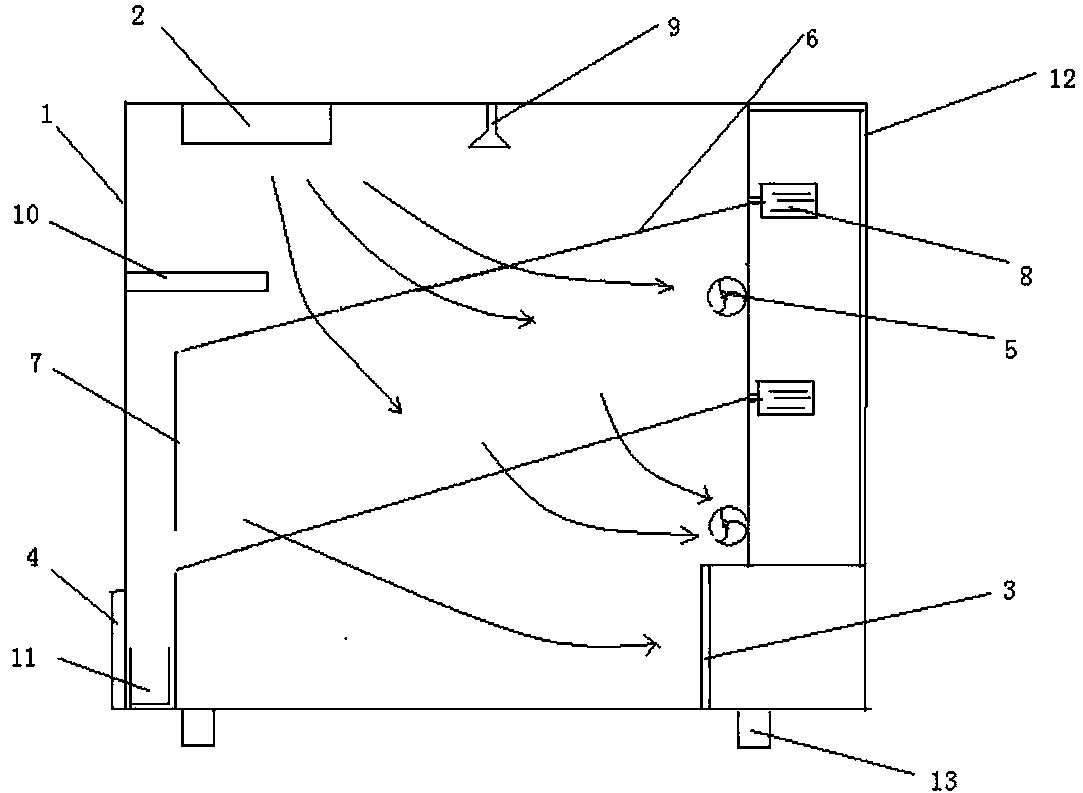

[0026] Specific embodiment 1, an environment-friendly dedusting equipment for a workshop, comprising a square housing 1 with a closed structure, an air inlet 2 is provided on the top side of the housing 1, and an outlet is provided on the corresponding right side and left side bottom of the housing. The tuyere 3 , the dust outlet 4 , the air inlet 2 and the air outlet 3 are all provided with protective nets, which can prevent external objects from falling into the housing 1 .

[0027] The inside of the housing 1 is provided with two layers of oblique filter screens 6, one end of the filter screen 6 is fixed on the side wall of the housing through an elastic member, and the other end is vertically provided with a first partition 7. Both sides of the partition 7 are affixed to the front and rear side walls of the housing 1; the filter screen 6 is inclined upward on the top of the first partition 7; the filter screen 6 passes through the high-strength The spring is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com