Lining insulating layer high-density ionic depositing method

A technology of ion deposition and insulating layer, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as the influence of leakage current of integrated devices, achieve the elimination of leakage current and other negative effects of integrated devices, and eliminate notches Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

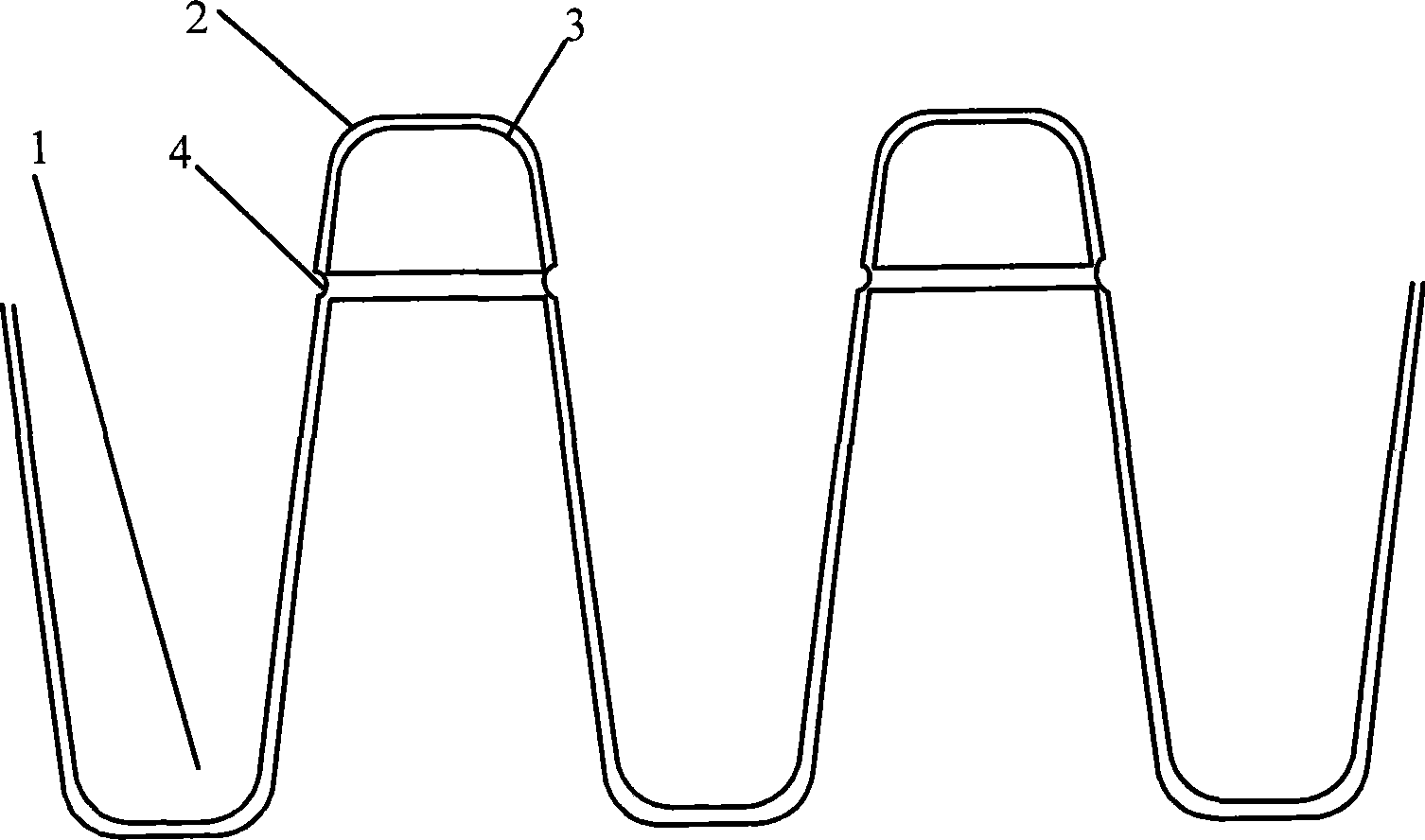

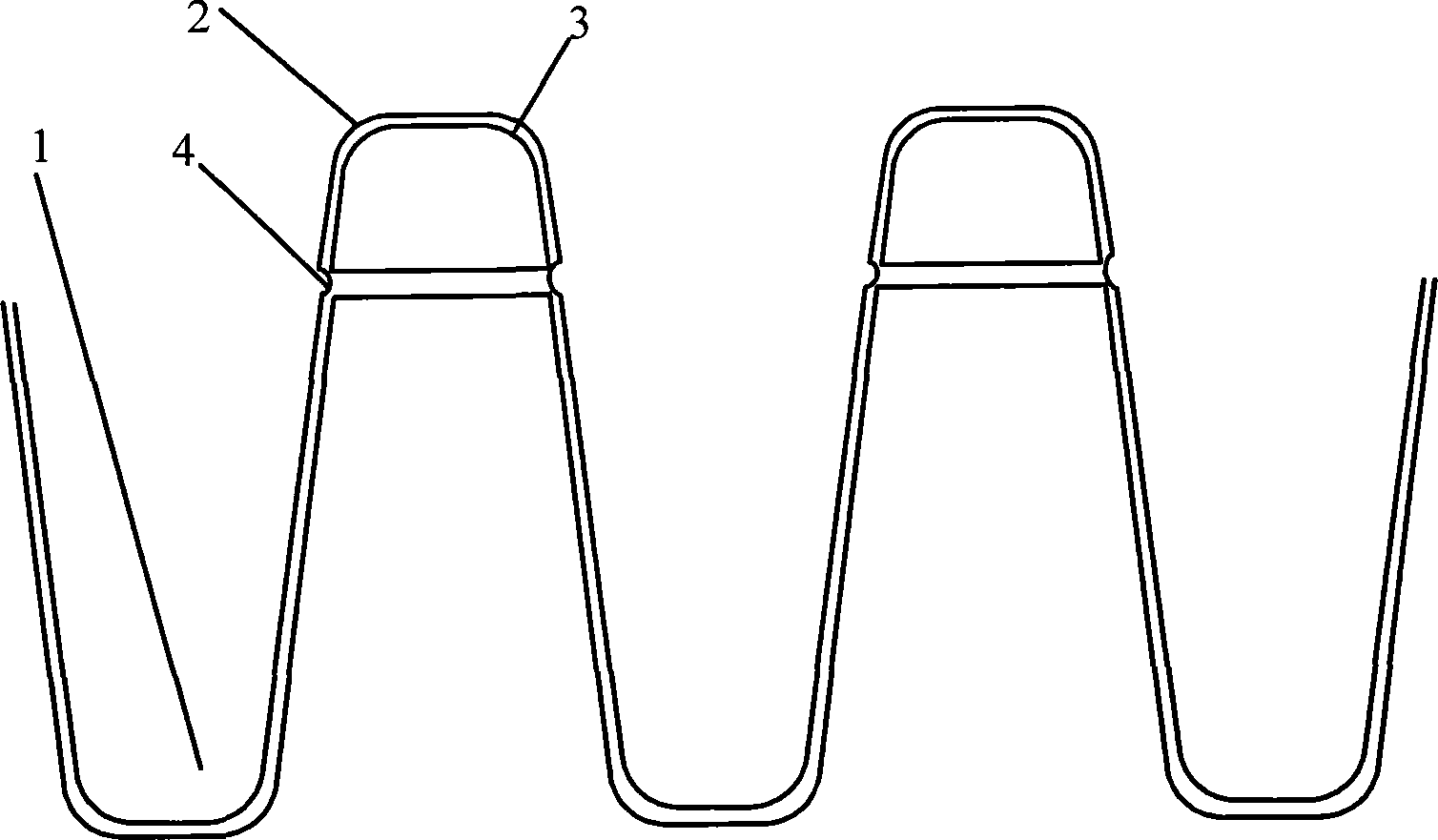

[0009] In the high-density ion deposition method of the insulating layer of the present invention, the high-density ion deposition of the insulating layer is carried out in a sealed reaction chamber. The top and side of the reaction chamber are connected with a reaction medium for forming an insulating layer and a conveying pipe for guiding the medium. The high-density ion deposition of the insulating layer uses radio frequency sputtering to deposit the insulating layer. The radio frequency sputtering includes two parameters: the decomposition power of the reaction medium and the sputtering power of the guiding medium used to guide the growth of the insulator. Wherein, the sputtering power of the guiding medium is 2.5-6.5 kilowatts, and the deposition time of the entire lining insulating layer is 3-15 seconds. Compared with the sputtering power of the guide medium used in the current conventional lining insulating layer, it can generate a denser guide medium flow, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com