Optical colorful thin film and manufacturing method thereof

A production method and colorful technology, applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problems of difficult appearance decoration, poor wear resistance, etc., and achieve improved performance and high wear resistance. , good colorful and beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

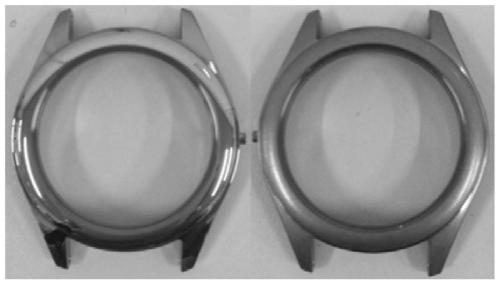

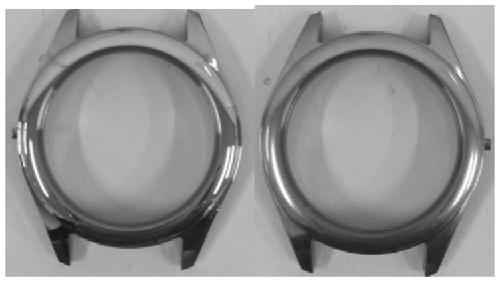

Image

Examples

Embodiment 1

[0055] 1. Charge a certain amount of Ar to start the arc power supply in a high vacuum state for ion cleaning, remove the fine dust on the surface of the product and activate its surface to increase the binding force between the membrane bases.

[0056] 2. Fill in 110-130sccm working gas Ar and 70-90sccm reaction gas O2, maintain the air pressure at 0.3pa-0.4pa, first turn on the titanium target, target current at 22-27A, deposit TiO2 layer, deposition time 25-35 minutes to form the first layer.

[0057] 3. Fill in 110-130sccm working gas Ar and 70-90sccm reaction gas O2, maintain the air pressure at 0.3pa-0.4pa, open the silicon target, target current at 18-22A, deposit SiO2 layer, deposition time 7-13 minutes , forming the second layer.

[0058] 4. Deposit the third and fifth layers with reference to the process parameters of the first layer, and deposit the fourth and sixth layers with reference to the process parameters of the second layer.

[0059] 5. Fill in 110-130scc...

Embodiment 2

[0061] 1. Charge a certain amount of Ar to start the arc power supply in a high vacuum state for ion cleaning, remove the fine dust on the surface of the product and activate its surface to increase the binding force between the membrane bases.

[0062] 2. Then fill in 120sccm of Ar and 80sccm of O2, the air pressure is 0.3pa-0.4pa, first open the titanium target to form a layer of dense TiO2 deposited on the product, the time is 27 minutes, and the first layer is formed at this time.

[0063] 3. Fill 120sccm of Ar and 80sccm of O2, turn on the silicon target to form a layer of dense SiO2 deposited on the product for 7 minutes, and form the second layer at this time.

[0064] 4. Deposit the third and fifth layers with reference to the process parameters of the first layer, and deposit the fourth and sixth layers with reference to the process parameters of the second layer.

[0065] 5. Fill in 110-130sccm working gas Ar and 70-90sccm reaction gas O2, maintain the air pressure a...

Embodiment 3

[0067] 1. Charge a certain amount of Ar to start the arc power supply in a high vacuum state for ion cleaning, remove the fine dust on the surface of the product and activate its surface to increase the binding force between the membrane bases.

[0068] 2. Then fill in 120sccm of Ar and 80sccm of O2, the air pressure is 0.3pa-0.4pa, first open the titanium target to form a layer of dense TiO2 deposited on the product, the time is 32 minutes, and the first layer is formed at this time.

[0069] 3. Fill in 120 sccm of Ar and 80 sccm of O2, turn on the silicon target to form a layer of dense SiO2 deposited on the product for 11 minutes, and form the second layer at this time.

[0070] 4. Deposit the third and fifth layers with reference to the process parameters of the first layer, and deposit the fourth and sixth layers with reference to the process parameters of the second layer.

[0071] 5. Fill in 110-130sccm working gas Ar and 70-90sccm reaction gas O2, maintain the air pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com