Briquette coal sample preparation device

A briquette and panel technology, applied in the field of laboratory equipment, can solve the problems of time-consuming, low success rate of sample preparation, coal sample not up to standard, etc., and achieve the effect of small labor, high success rate of sample preparation, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

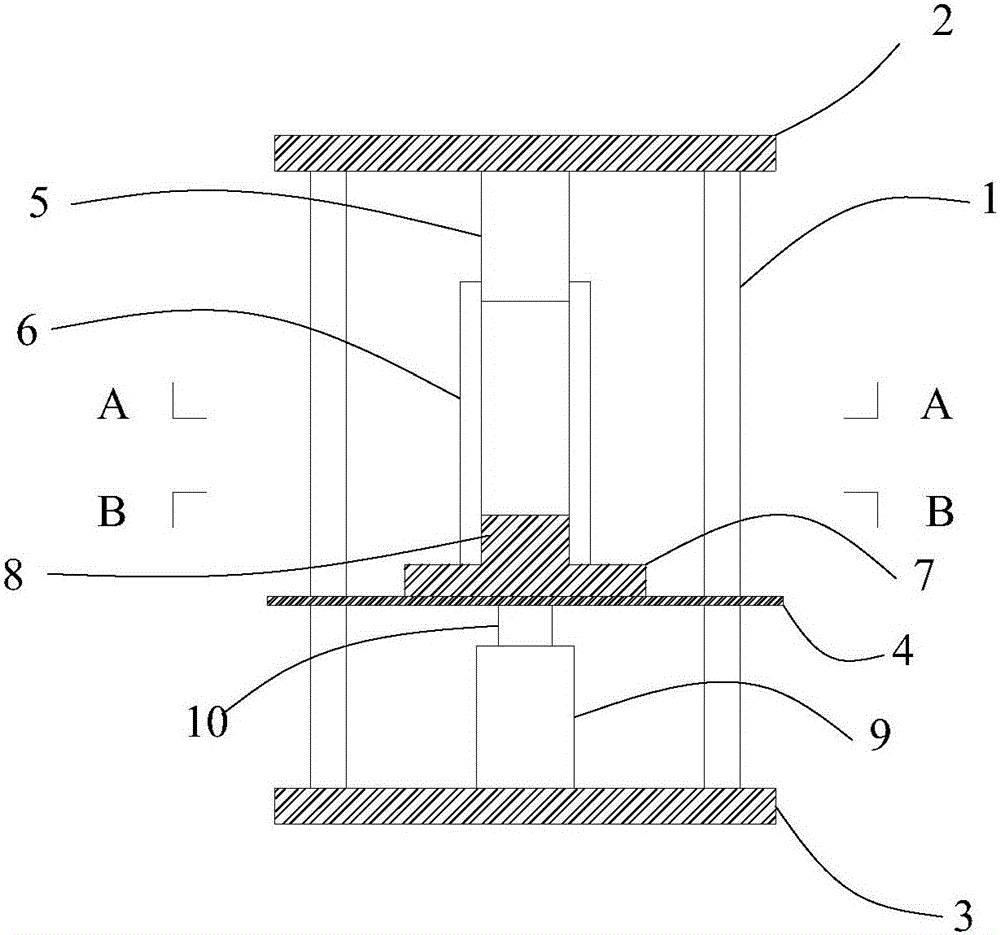

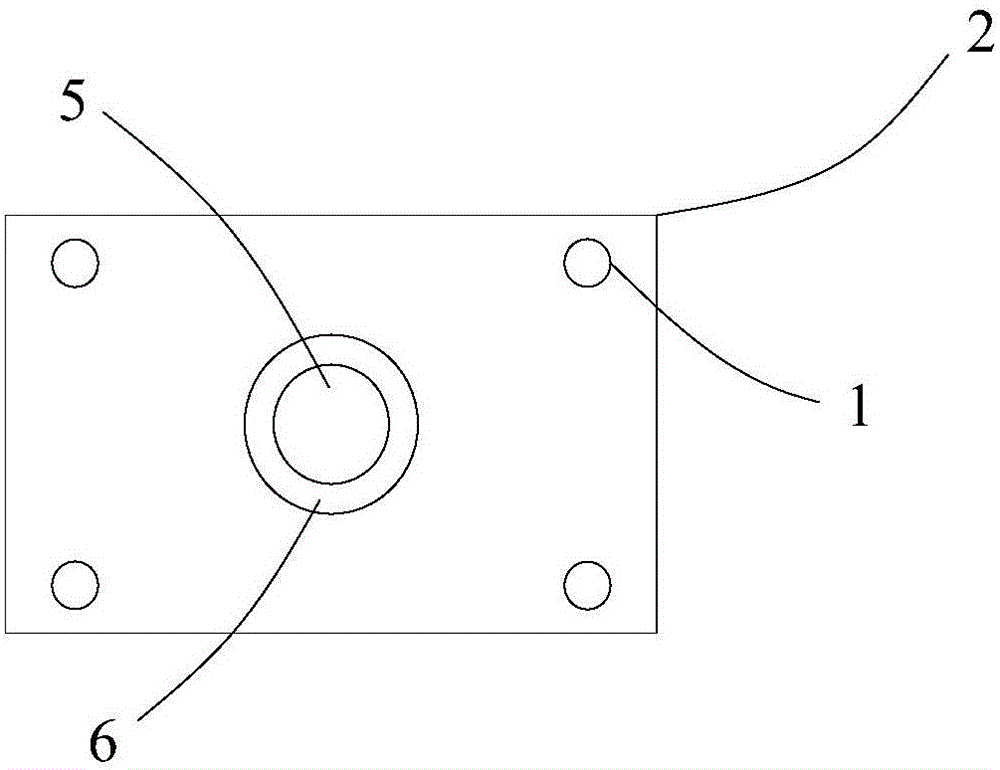

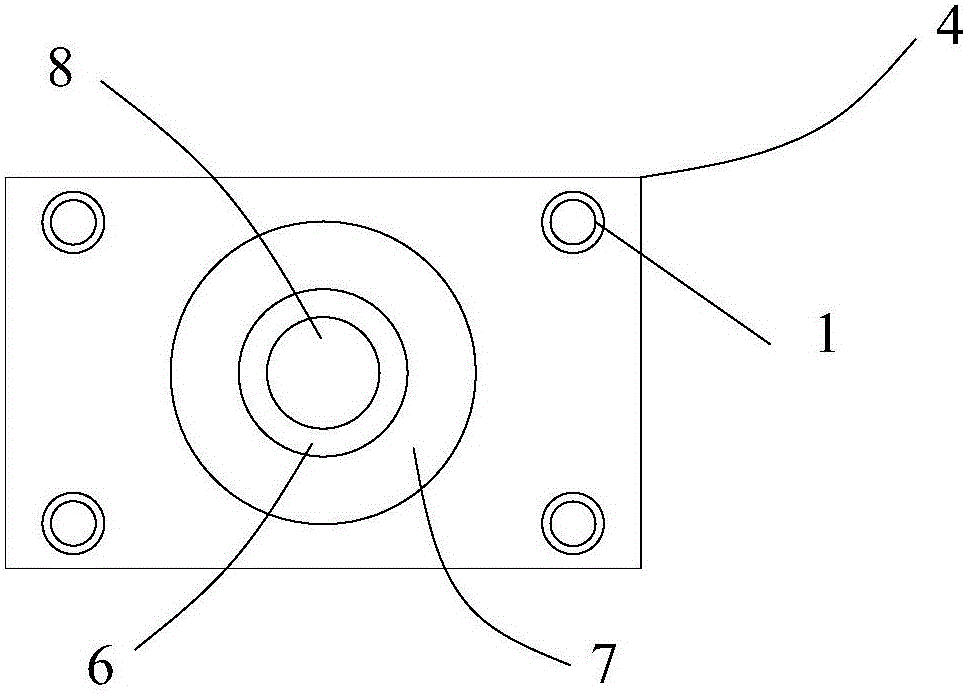

[0012] The present invention will be further described below in conjunction with accompanying drawing:

[0013] Such as figure 1 , 2 , shown in 3, a kind of briquette sample preparation device is characterized in that: comprise column (1), upper panel (2), lower panel (3), middle panel (4), spacer (5), hollow cylinder (6), chassis lower part (7), chassis upper part (8), jack (9), jack piston rod (10); said chassis lower part (7) and chassis upper part (8) are consolidated into one; said hollow cylinder (6) The inner surface is smooth; the spacer (5) can be fully extended into the cylinder (6), and is in close contact with the inner wall of the cylinder (6); there are four columns (1), and the columns (1) Through the middle panel (4), the two ends are respectively fixed on the upper panel (2) and the lower panel (3); the jack (9) is placed at the center of the lower panel (3).

[0014] Attached below figure 1 , 2 , 3 specifically illustrate the use method of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com