Test method for interfacial bonding strength of ceramic fiber reinforced resin matrix composites

A technology of interfacial bonding strength and reinforced resin base, which is applied in the field of ceramic fibers, can solve the problems of difficult test sample preparation and low test efficiency, and achieve the effects of improving the success rate of sample preparation, efficient measurement, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings. The embodiments are only to further illustrate the content of the invention, and are not intended to limit the content of the invention.

[0033] The following is an example of testing the fiber-matrix interface bonding strength of silicon carbide fiber-reinforced epoxy resin-based composite materials.

[0034] Raw material: SiC fiber: 14μm in diameter, 30mm in length, 10 pieces;

[0035] Carrier for discharging fibers: rectangular hollow cardboard;

[0036] Quick-drying glue: 502 glue;

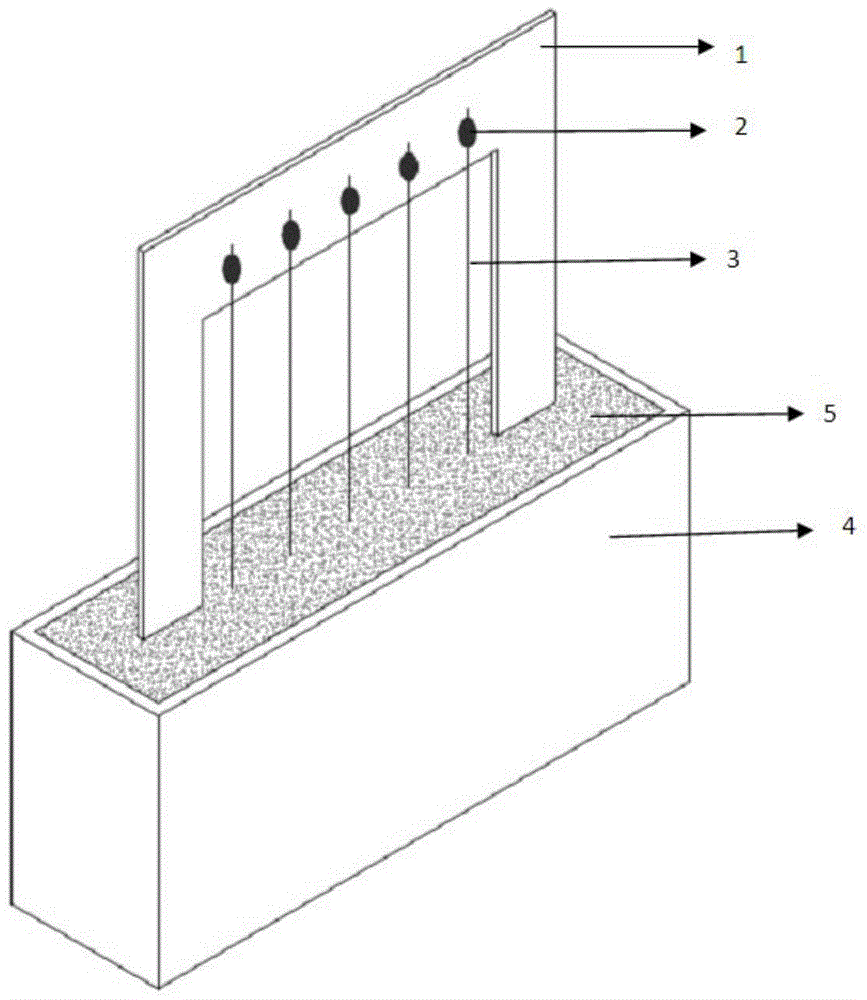

[0037]Embedding resin system: E40 epoxy resin 100 parts, ethylenediamine 14 parts;

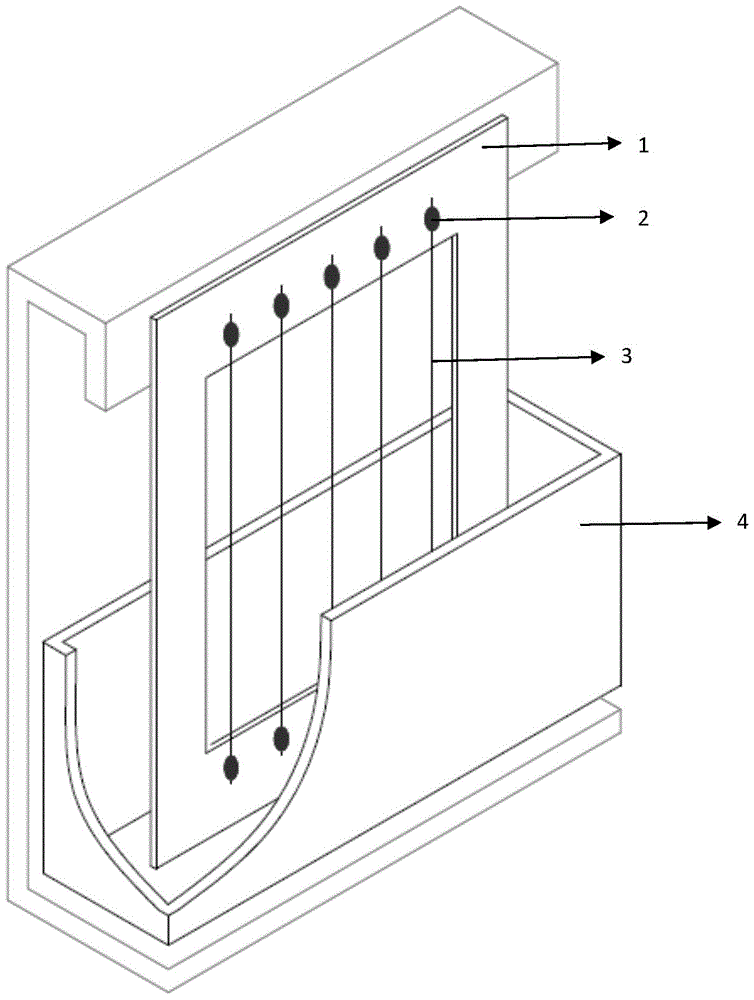

[0038] Mold: aluminum cuboid hollow groove.

[0039] Sample preparation process:

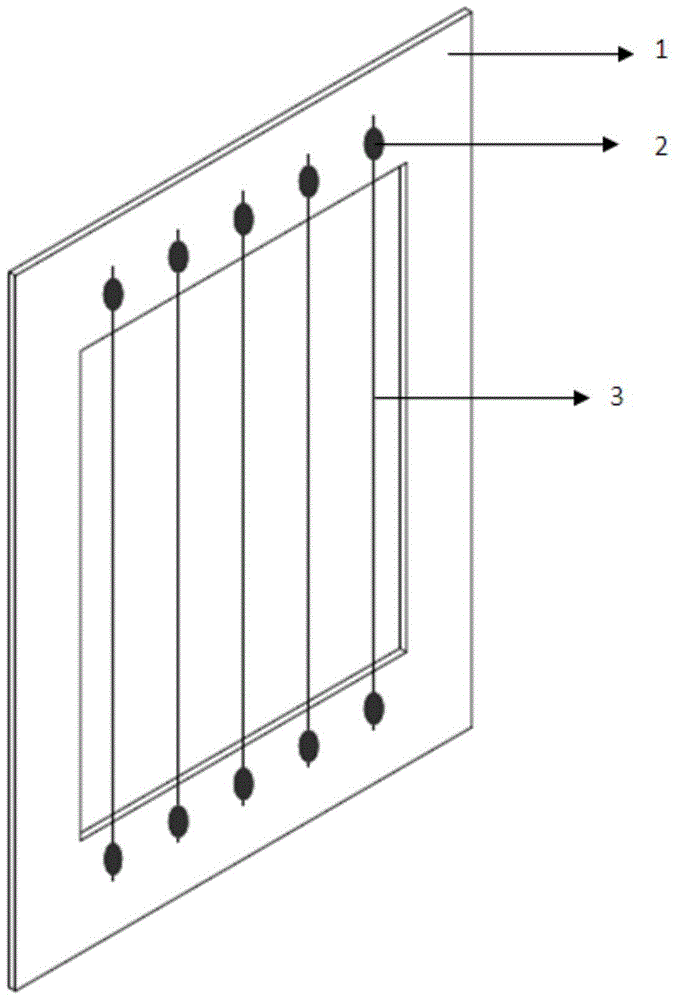

[0040] Use 502 glue to bond 10 silicon carbide single fibers in parallel on a hollow cardboard frame printed with scale lines. The size of the outer frame is 50mm×35mm, the size of the inner frame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com