A sample preparation process of undisturbed triaxial sample of spin-down type soil

A technology of triaxial sample and undisturbed soil, which is applied in the field of indoor geotechnical testing of civil engineering disciplines, can solve the problems that the proficiency of sample preparation personnel is greatly affected, the success rate of sample preparation is not high, and the operation steps are cumbersome, so as to improve the production efficiency. The effect of improving the sample success rate, avoiding the influence of uncertain factors and human factors, and simplifying the operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described in detail in conjunction with specific examples below.

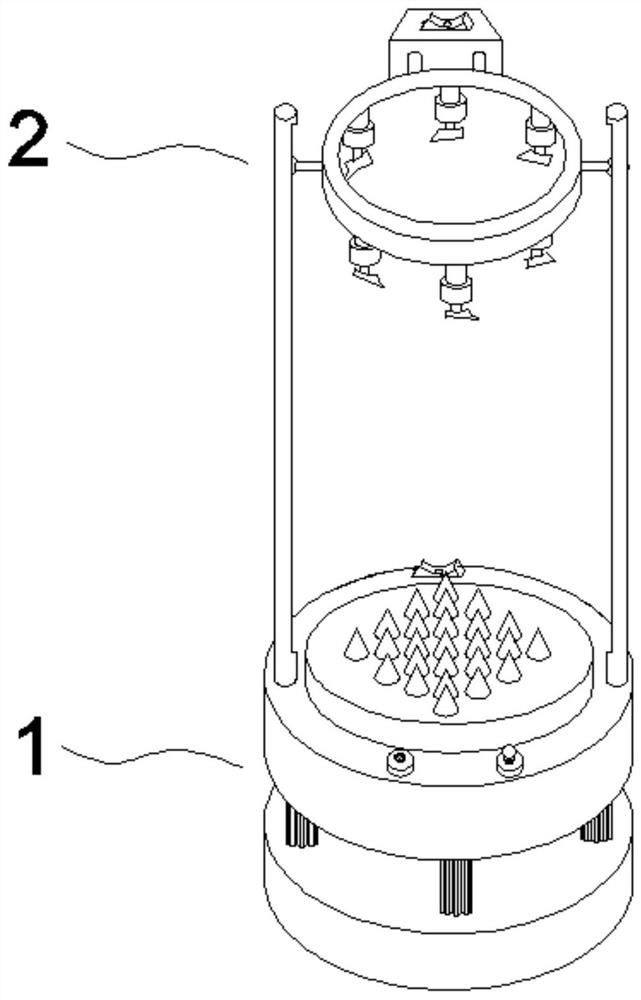

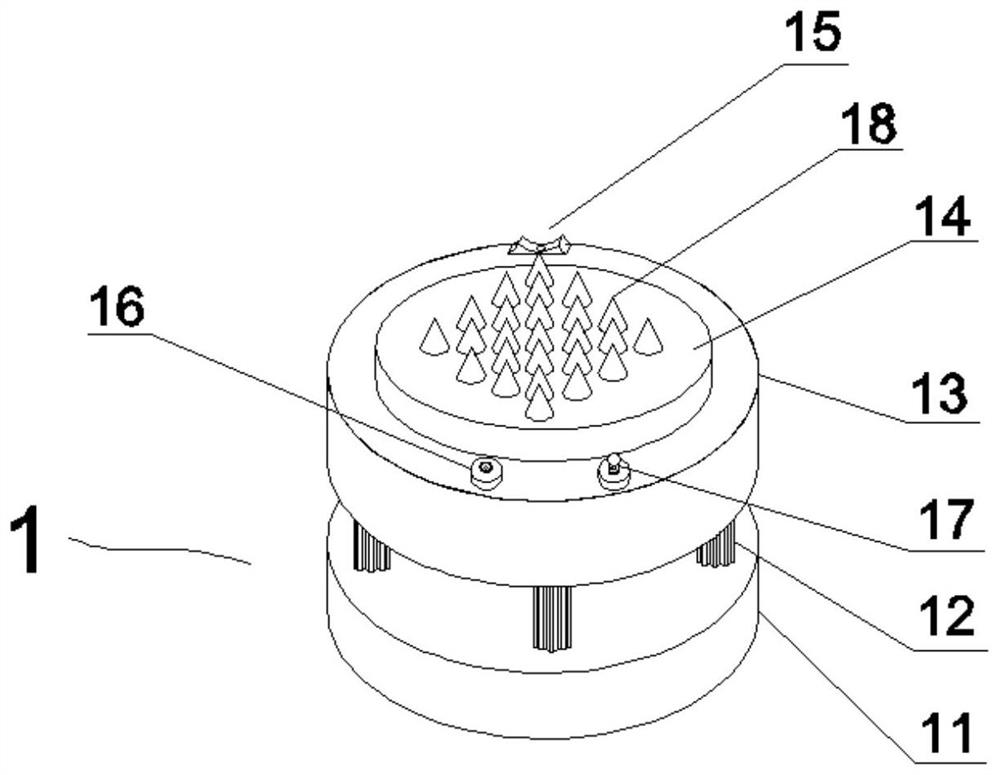

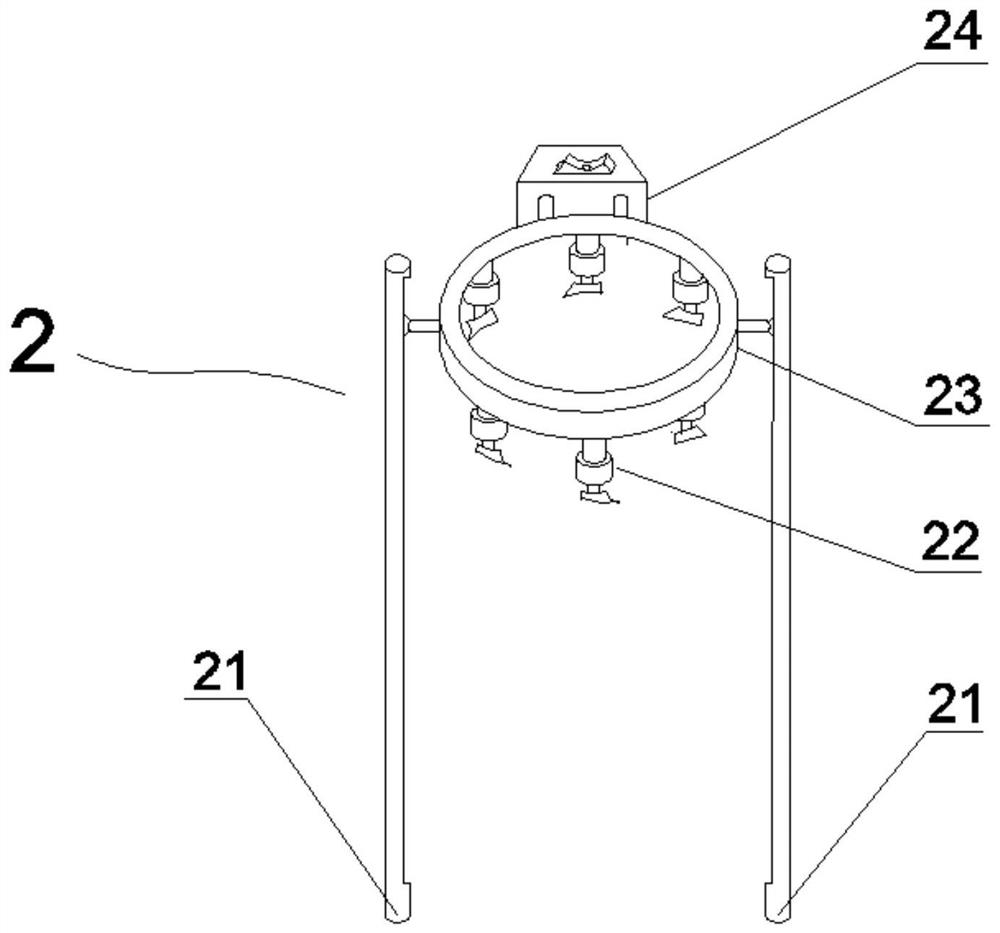

[0049] combine Figure 1-Figure 10 As shown, a spin-down undisturbed soil triaxial sample preparation device of the present invention includes a support mechanism 1 , a cutting mechanism 2 , and a sample receiving mechanism 3 .

[0050] The support mechanism 1 includes a lower base 11, a leveling nut 12, an upper base 13, a nail plate 14, a lifting switch 15, a level bubble 16, a warning light 17, and a steel nail 18. The lower base 11 is located at the bottom, and the upper base 13 is located on Above the lower base 11, the leveling nut 12 is located between the lower base 11 and the upper base 13, the nail plate 14 is fixed on the upper base 13, the lifting switch 15, the level bubble 16, and the warning light 17 are all installed on the upper base 13. The outer edge of the upper surface, wherein the level bubble 16 is adjacent to the warning light 17 left and rig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com