Preparation method of transmission electron microscope sample

A technique for TEM samples and samples, which is applied in the preparation, sampling, and sampling devices of test samples, and can solve the problems of inconsistent cutting speed, curtain effect, and easy to produce stretch marks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

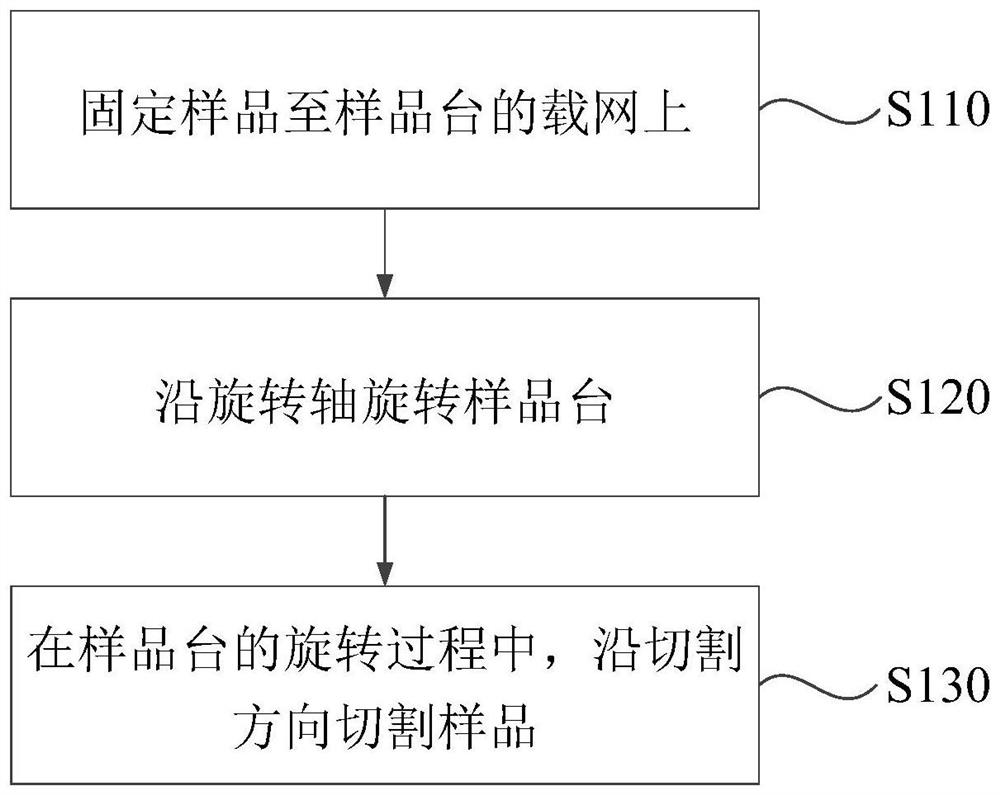

[0044] figure 1 A flow chart of a method for preparing a transmission electron microscope sample provided by an embodiment of the present invention, such as figure 1 Shown, this preparation method comprises:

[0045] S110, fixing the sample on the carrier grid of the sample stage.

[0046] Specifically, firstly, the carrier net can be installed on the sample platform, and then the sample can be fixed on the carrier net. Carrier grid is a common vocabulary in the field of transmission electron microscope sample preparation, and it can also be called copper grid, microgrid, etc. The type of carrier grid can be selected according to actual needs, which is not limited in the embodiment of the present invention. It can be understood that the above-mentioned sample is a tiny sample including the position to be detected, and the sample includes a surface to be thinned, and in the subsequent sample preparation process, the surface to be thinned of the sample is cut to thin the sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com