Ceramic fiber resistivity testing method

A ceramic fiber and testing method technology, applied in the direction of measuring resistance/reactance/impedance, measuring device, measuring electrical variables, etc., can solve problems such as errors in circuit connection methods, avoid damage, avoid interference from electromagnetic fields and electrostatic effects, and improve The effect of sample preparation success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

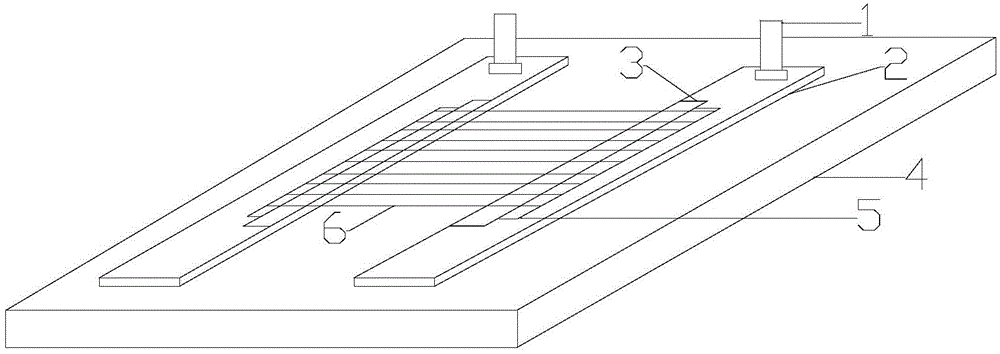

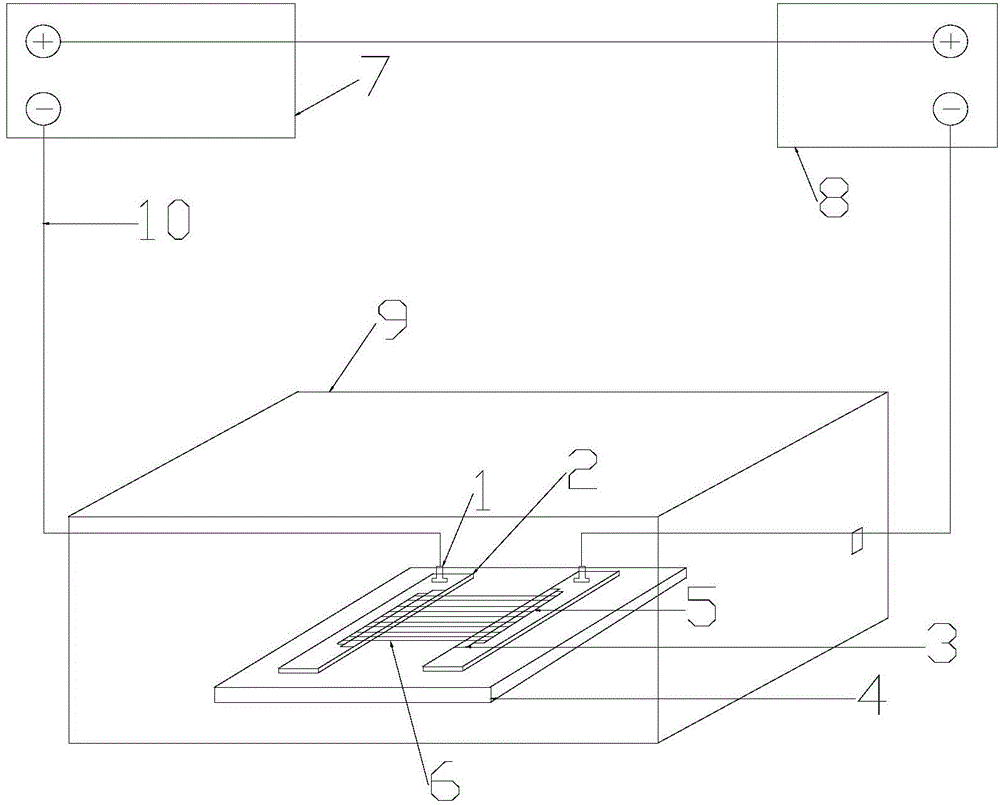

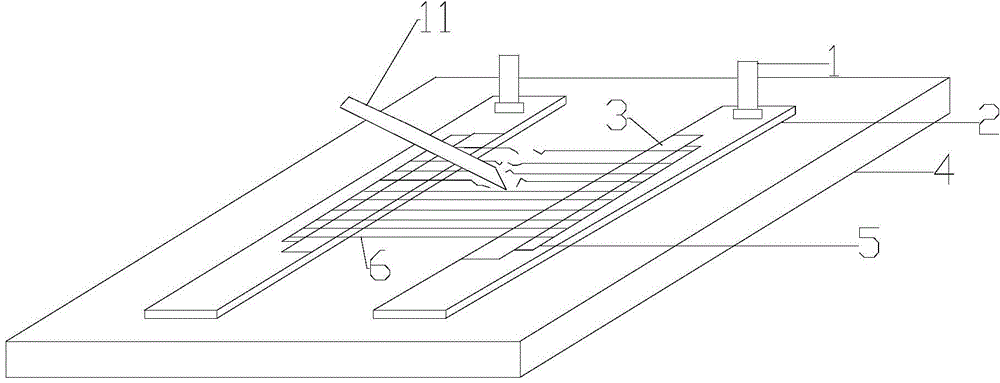

[0029] see Figure 1~3 , to measure the resistivity of continuous SiC fibers

[0030] Raw material: continuous silicon carbide fiber 6; length after cutting is 30mm, 10 pieces;

[0031] Metal plate sample table 2: the bottom is a 120mm×100mm plastic insulating plate 4, and two parallel copper plates are fixed on the upper end, the distance between the plates is 25mm, and the size of the copper plate is 70mm×20mm×5mm;

[0032] Double-sided tape 3: the width is 8mm;

[0033] Conductive silver paste 5: SPI;

[0034] Copper wire 10: several pieces;

[0035] wire terminal 1;

[0036] Blade 11: common blade.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com