Method determining impurity content in stannic oxide electrode material

A technology of impurity content and electrode material, which is applied in material excitation analysis, preparation of test samples, thermal excitation analysis, etc. Small error, high success rate of sample preparation and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

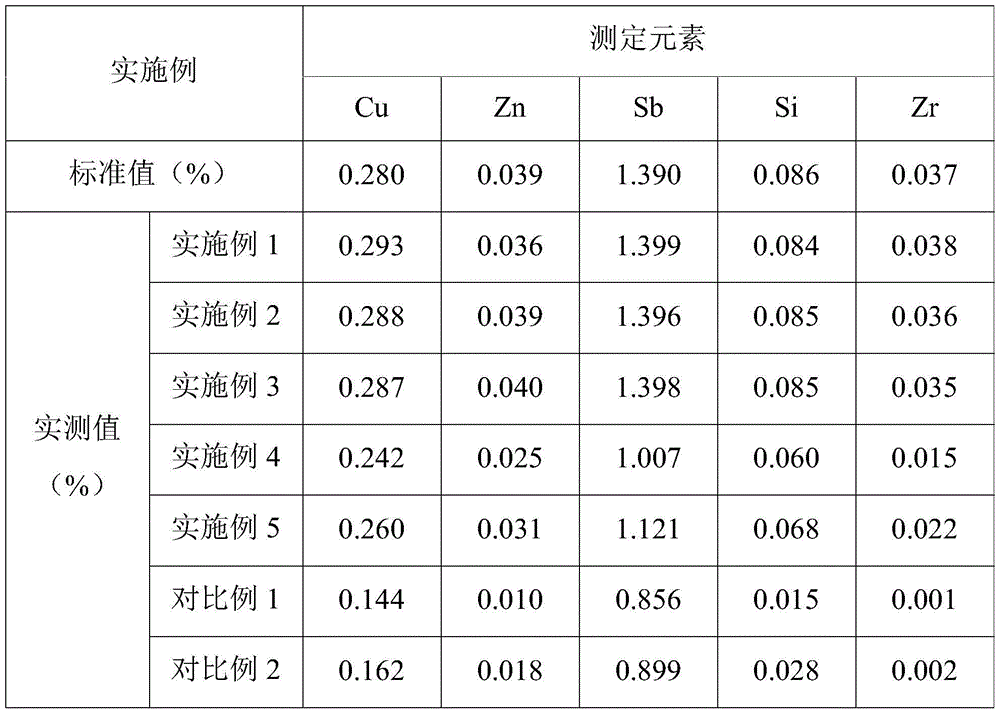

Examples

Embodiment 1

[0032] (1) Grind a tin oxide electrode sample with known impurity content until it has no graininess, put it in a weighing bottle, dry it in an oven at 110°C for 2 hours, take it out and cool it to room temperature in a desiccator. After adding 1g of lithium tetraborate and 2g of lithium metaborate into the platinum crucible, accurately weigh 0.1000g (accurate to 0.0001g) of the tin oxide electrode sample in it, and then add 1g of sodium hydroxide solid to cover it; place the platinum crucible Heat at 1000°C for 10 minutes in a high-frequency melting furnace; take out the platinum crucible, take out the melt piece after cooling, put it in a beaker and add 200g of pure water, then pipette 15g of high-grade pure concentrated hydrochloric acid with a concentration of 36.5%, and place Heat and dissolve on an electric furnace to obtain a clear and transparent solution, and transfer it to a 250mL volumetric flask;

[0033] (2) Prepare the standard solution of standard addition sampl...

Embodiment 2

[0036](1) Grind a tin oxide electrode sample with known impurity content until it has no graininess, put it in a weighing bottle, dry it in an oven at 110°C for 2 hours, take it out and cool it to room temperature in a desiccator. After adding 0.4g lithium tetraborate and 2g lithium metaborate into the platinum crucible, accurately weigh 0.1000g (accurate to 0.0001g) tin oxide electrode sample in it, then add 0.5g sodium hydroxide solid to cover it, and make samples at the same time Blank test; place the platinum crucible in a high-frequency melting furnace and heat it at 1000°C for 15 minutes; take out the platinum crucible, take out the melting piece after cooling, put it in a beaker, add 230g of pure water, and pipette 8g with a concentration of 65% The superior grade pure concentrated nitric acid is placed on an electric furnace for heating and dissolving to obtain a clear and transparent solution, which is transferred to a 250mL volumetric flask; step (2), step (3) are con...

Embodiment 3

[0038] (1) Grind a tin oxide electrode sample with known impurity content until it has no graininess, put it in a weighing bottle, dry it in an oven at 110°C for 2 hours, take it out and cool it to room temperature in a desiccator. After adding 0.1g lithium tetraborate and 0.8g lithium metaborate into the platinum crucible, accurately weigh 0.1000g (accurate to 0.0001g) tin oxide electrode sample in it, then add 0.2g sodium hydroxide solid to cover it, and do Sample blank test; place the platinum crucible in a high-frequency melting furnace and heat it at 1000°C for 20 minutes; take out the platinum crucible, take out the melting piece after cooling, put it in a beaker, add 230g of pure water, and pipette 5g with a concentration of 72 The superior grade pure perchloric acid of % is placed on electric furnace heating and dissolving to obtain clear and transparent solution, is transferred in the 250mL volumetric flask; Step (2), step (3) are consistent with embodiment 1, and test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com