Sample preparation toolkit for determining curing temperature of high-solid-content propellant powder and use method of sample preparation toolkit

A technology with high solid content and aging temperature, which is applied in the field of physical and chemical performance detection and research of launch drugs, can solve the problems of large sample preparation loss, poor sample preparation repeatability, collapse and splashing, etc. The effect of high sample success rate and small sample preparation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] The composition of propellant sample A is 30% of NC, 16% of NG, and 54% of solid additives such as NQ. It is made into 8 cylinders with a diameter of 14mm and a height of 15mm, none of which has been matured.

[0092] A sample preparation kit for determining the aging temperature of propellants with high solid content, the sample preparation kit includes a sample preparation knife 1, a sample preparation cover 2, a sample preparation tray 3, and a hammer;

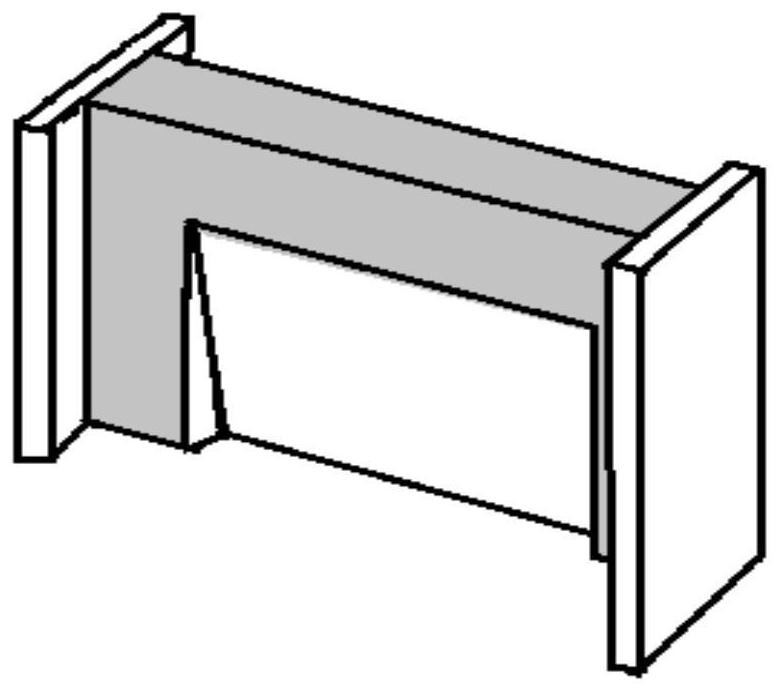

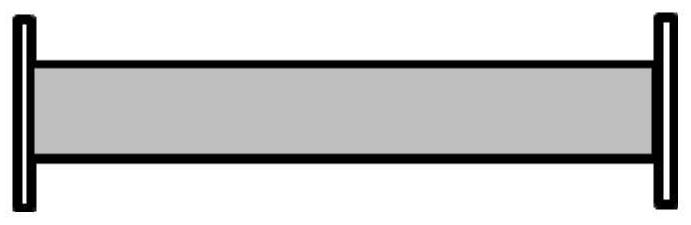

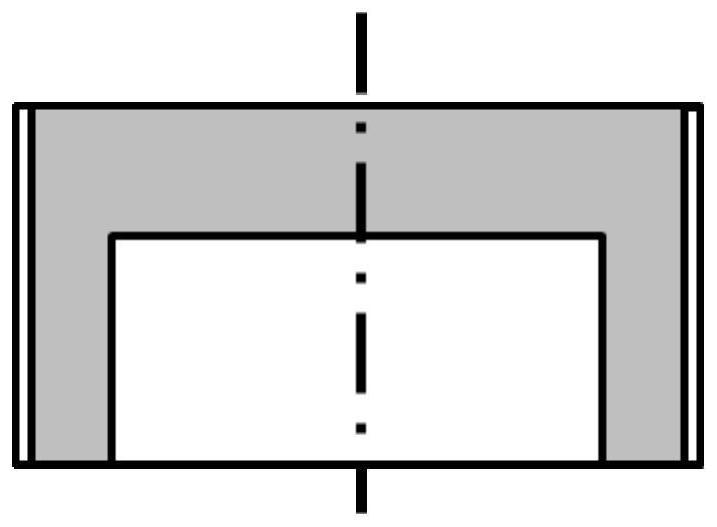

[0093] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the sample preparation knife 1 is composed of three parts: the outer, the middle, and the inner. It is the blade body; there are 2 control plates of the sample preparation knife 1, both of which are flat plates with a height of 13 mm, a width of 2 mm, and a thickness of 7 mm. The height and thickness of the control plates form the side of the control plate; The outer height of the handle is 13mm, the inner height is 8mm, the outer width is 22m...

Embodiment 2

[0108] The composition of propellant sample B is 30% of NC, 16% of (NG+DIANP) and 54% of solid additives such as NQ. It is made into 8 cylinders with a diameter of 14mm and a height of 15mm, none of which has been matured.

[0109] A sample preparation kit for determining the aging temperature of propellants with high solid content, the sample preparation kit includes a sample preparation knife 1, a sample preparation cover 2, a sample preparation tray 3, and a hammer;

[0110] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the sample preparation knife 1 is composed of three parts: the outer, the middle, and the inner. It is the blade body; there are 2 control plates of the sample preparation knife 1, both of which are flat plates with a height of 13 mm, a width of 2 mm, and a thickness of 7 mm. The height and thickness of the control plates form the side of the control plate; The outer height of the shank is 13mm, the inner height is 8mm, the outer width ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com