Method for making sample of chemical deposited nickel fixed alloy powder for transmission electron microscope observing

A technology for chemical deposition of nickel and chemical deposition, which is applied in the field of sample preparation for transmission electron microscopy experiments, can solve the problems of low success rate, high cost, complicated electroplating method and process flow, etc., and achieves the effect of high sample preparation success rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

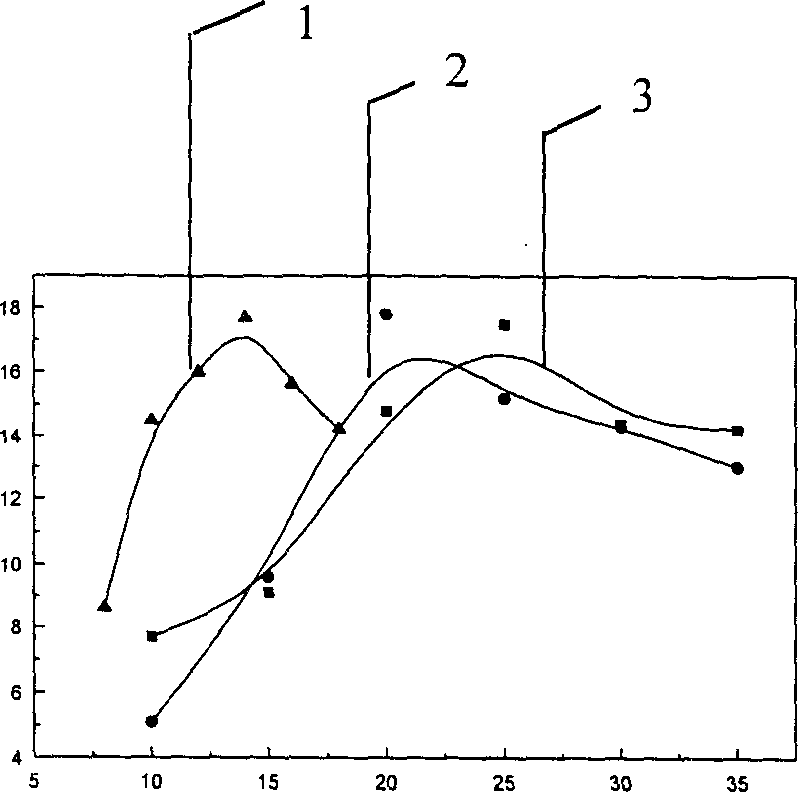

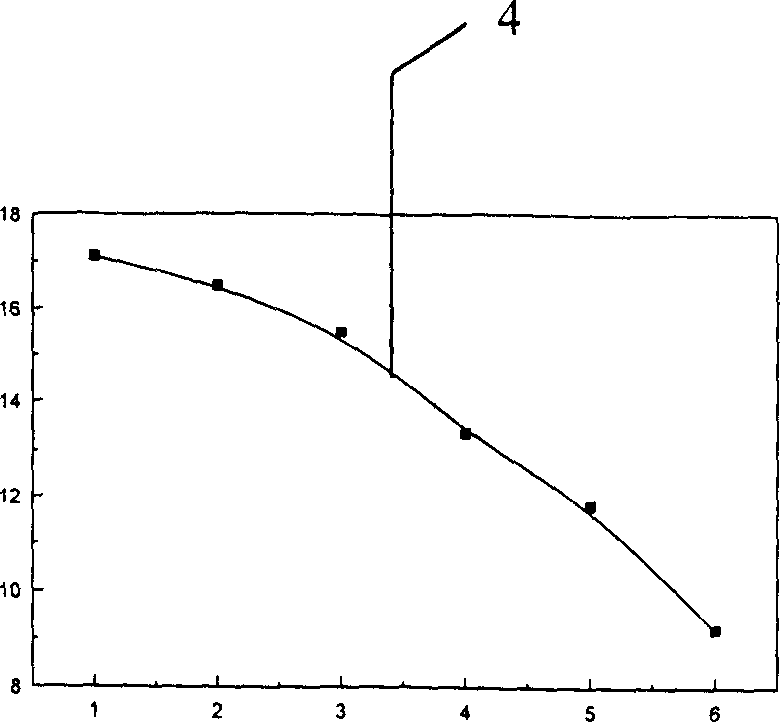

[0027] 1. Determination of chemical deposition ratio and experimental conditions

[0028] Pre-test chemical nickel plating deposition solution formula and experimental conditions are as follows:

[0029] Deposition solution: nickel sulfate (25g / l) + sodium hypophosphite (22.5g / l) + anhydrous sodium acetate (15g / l) + citric acid (2g / l) + lead acetate (5 drops / l);

[0030] PH value of deposition solution: 4.6;

[0031] Experimental temperature: 88°C.

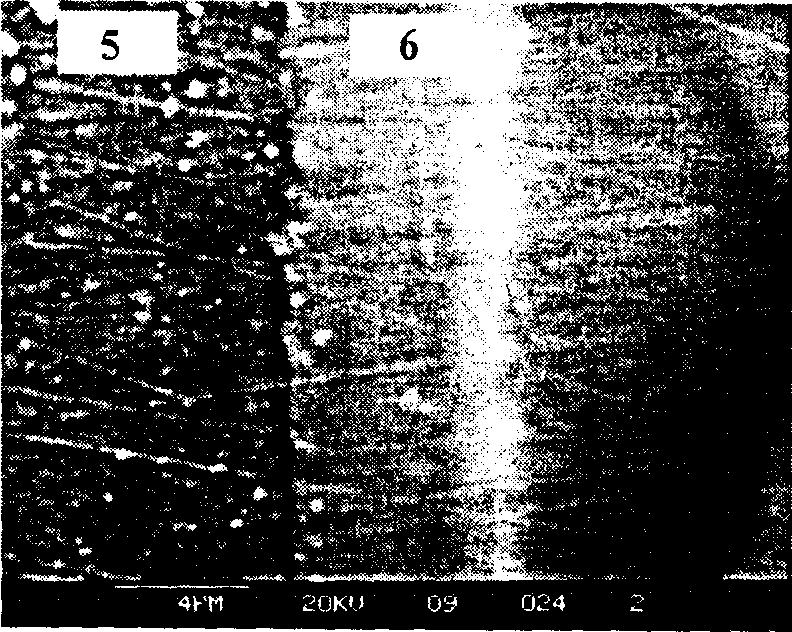

[0032] Substrate and powder: wash with 5% hydrochloric acid alcohol solution (30 minutes), and then evenly distribute nickel-based powder superalloy (FGH95) powder particles (Φ50-150μm) on the activated copper block

[0033] In order to determine the optimal ratio of deposition solution and find out the influence rules of various factors, the influence of nickel sulfate content, sodium hypophosphite content, sodium acetate content and citric acid content on the deposition rate was done by using mathematical statistics orthogonal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com