An automated method for sample thinning

A sample and metal technology, applied in the field of automated sample thinning, can solve the problems of high failure probability of sample preparation, imprecise slicing position, and low degree of automation, and achieve high sample preparation success rate, low labor cost, and high degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

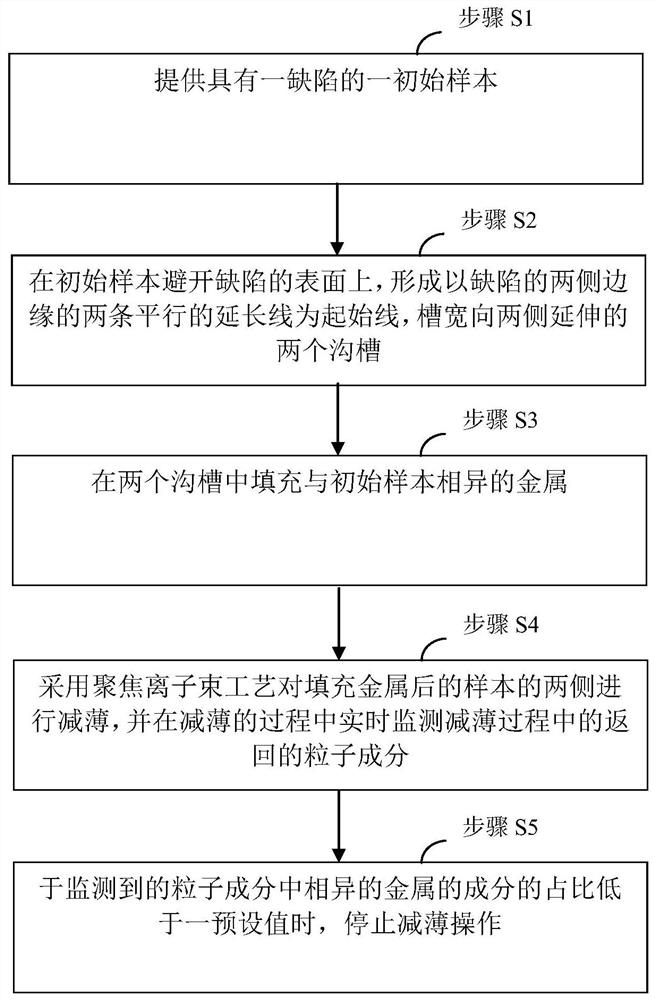

[0023] In a preferred embodiment, as figure 1 with figure 2 As shown, an automated sample thinning method is proposed for the preparation of a failure analysis sample; which may include:

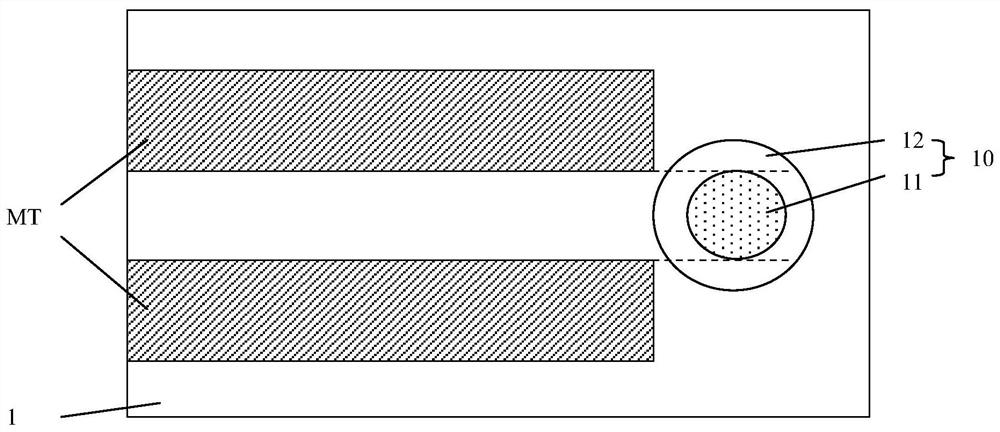

[0024] Step S1, providing an initial sample 1 with a defect 10;

[0025] Step S2, on the surface of the initial sample 1 avoiding the defect 10, forming two grooves starting from two parallel extension lines of the edges on both sides of the defect 10 and extending to both sides in groove width;

[0026] Step S3, filling the two grooves with metal MT different from the initial sample;

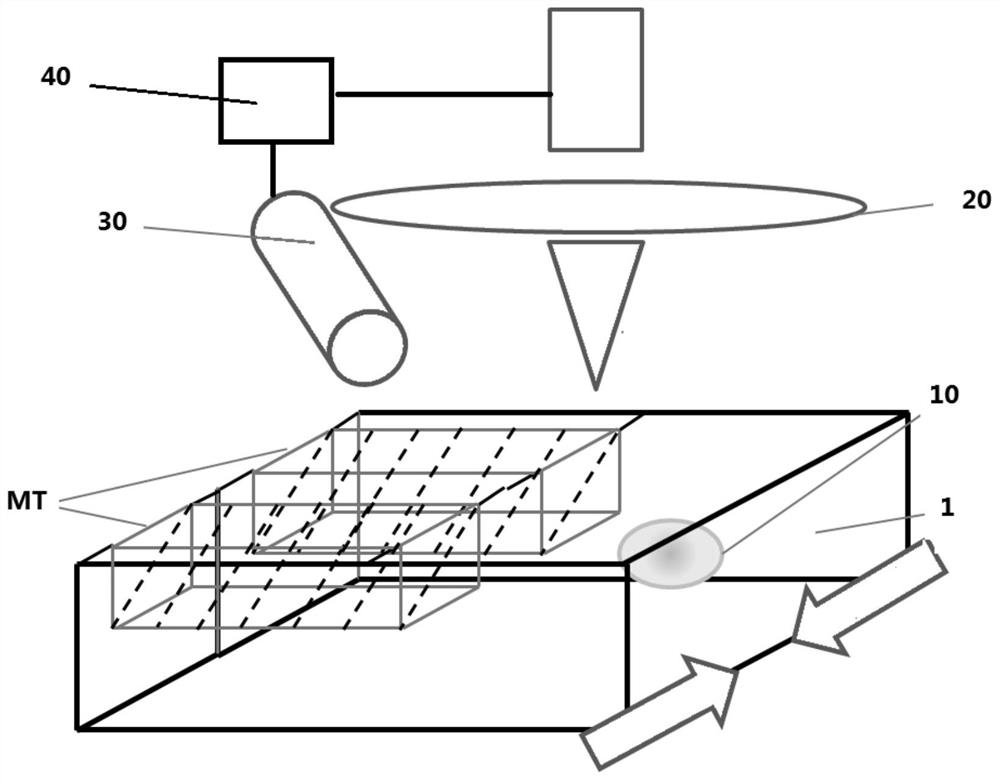

[0027] Step S4, using focused ion beam technology to thin both sides of the sample filled with metal MT, and monitor the returned particle composition in the thinning process in real time during the thinning process;

[0028] Step S5 , when the proportion of different metal MT com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com