A Floating Cutter Head That Can Automatically Find the Longitudinal Slit of Towel Blank

A technology of automatic search and blank, which is applied in the cutting of textile materials, textiles and papermaking, etc. It can solve the problems of automatic knife setting, uncontrollable size of towel setting, and reduced production efficiency, so as to reduce the damage rate and wide detection range , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

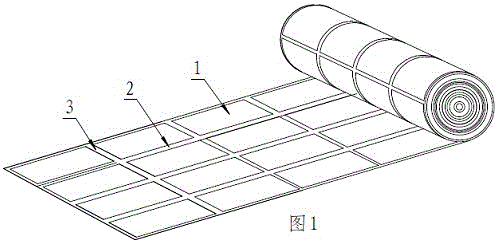

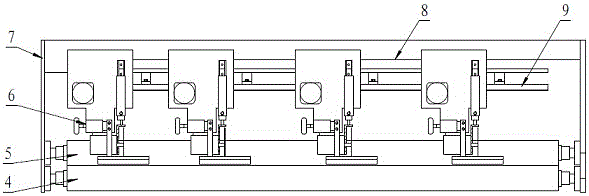

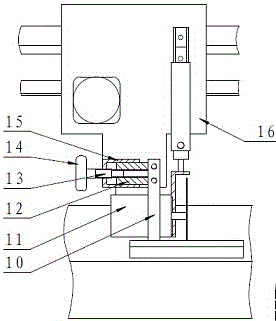

[0034] see Figure 2-Figure 4 , multiple floating cutter heads are installed on each towel blank slitting device, and each floating cutter head corresponds to a slitting slit 2 . The mechanical part of the present invention comprises horizontal track 8, vertical slideway (not shown in the figure), rack 9, sensor support 10, traverse motor M, cutting motor 11, adjustment slide block 12, adjustment bolt 13, adjustment hand Wheel 14, adjustment cover 15, floating base 16, blade 18, lifting cylinder 19, slide block 20 and gear 21. The floating base 16 is fixed on the slide block 20 on the horizontal rail 8 and can slide freely along the horizontal rail 8. The rack 9 is fixed on the frame 7. The traverse motor M on the floating base 16 drives the gear 21 to rotate, and the gear 21 and The tooth bar 9 is engaged; the blade 18 driven by the cutting motor 11 is arranged on the floating base 16, and the towel blank can be cut. There is a fabric guide roller at the front and back of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com