A peeling tool with precise adjustment of cutting depth

A cutting depth, stripping tool technology, applied in the direction of dismantling/armoured cable equipment, etc., can solve the problems that the wallpaper knife is difficult to cut, the cutting operation is difficult, and the cutting work is easy to hurt hands, etc., to achieve the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

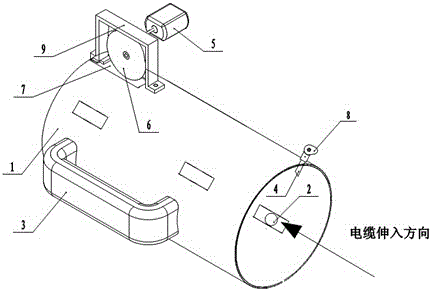

[0020] refer to figure 1 , the present invention is provided with cylindrical sleeve 1 and the cutting knife 4 that stretches into the sleeve 1, when cutting the cable, the cable stretches in the sleeve 1, at this moment, adjust the depth of the cutting knife 4 cutting into the cable sheath, and then Open the motor 5, the output shaft of the motor 5 drives the friction wheel 6 to rotate, the outer circumference of the friction wheel 6 is rough and has strong friction, the friction wheel 6 passes through the long hole 7 to compress the power cable, when the friction wheel 6 rotates, use The friction pulling power cable between the friction wheel 6 and the power cable advances in the sleeve, and both hands fix the sleeve 1, so that the cutter 4 cuts the cable sheath along the cable axial direction.

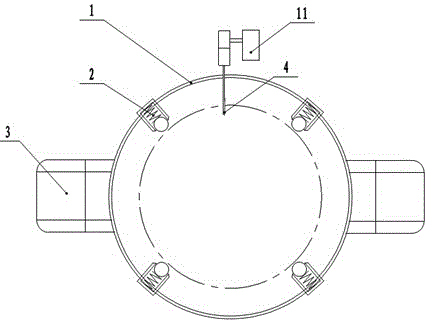

[0021] refer to figure 2 , 3 , the top of the cutter 4 among the present invention is provided with a knife rest 10, except that the knife rest 10 is used for fixing the cutter, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com