An inorganic full-solid electric driven color-changing part making method

An electrochromic, all-solid-state technology, applied in the direction of color-changing fluorescent materials, chemical instruments and methods, optics, etc., can solve the problems of high price, easy diffusion of ions, unsatisfactory service life and coloring stability, and achieve modulation The effect of large range, promotion of research and application, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

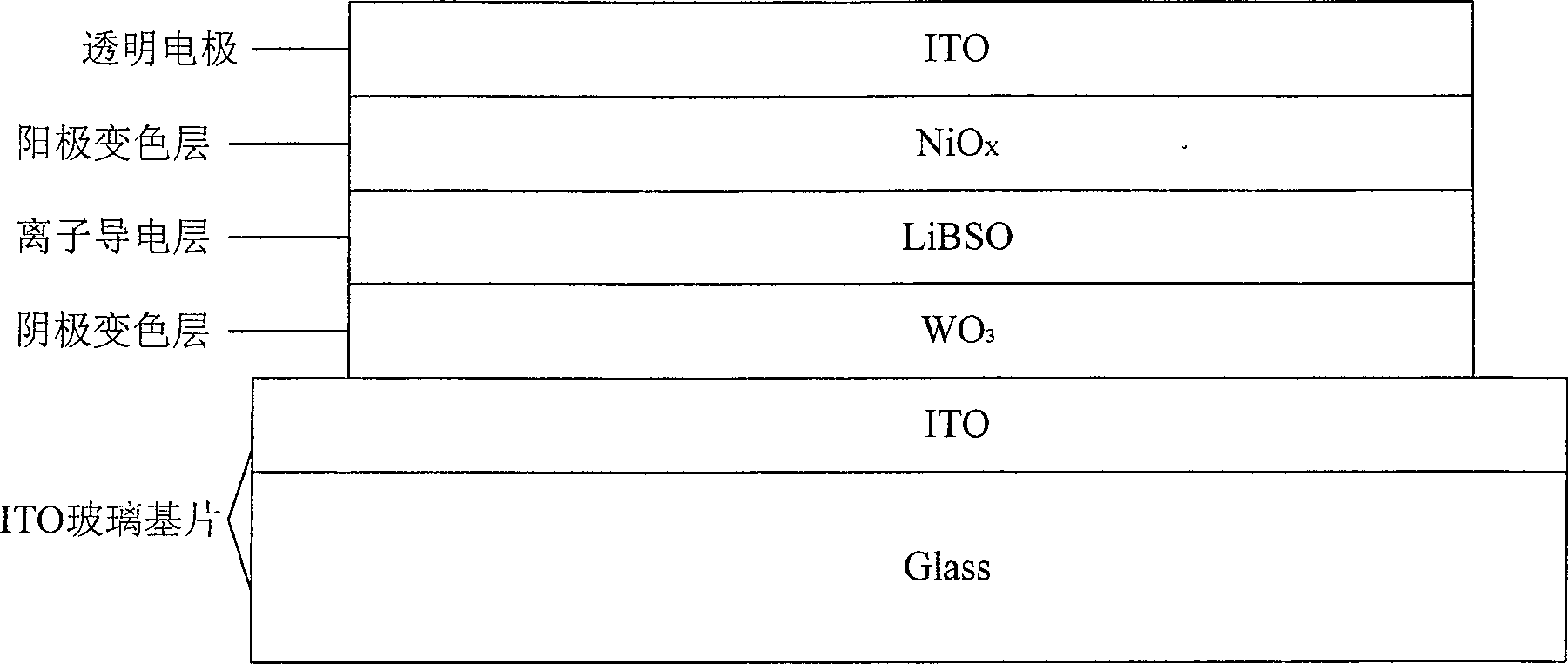

[0091] (1) Preparation of the substrate

[0092] The purchased ITO conductive glass was cut into 2×3cm substrates, and the cut substrates were ultrasonically cleaned in acetone for 2 hours, then ultrasonically cleaned with absolute ethanol for 2 hours, and finally cleaned in deionized water for 2 hours to obtain Spare ITO glass substrate; this substrate is installed on the sample support of multi-target magnetron sputtering.

[0093] (2) vacuuming

[0094] Open the sputtering film forming chamber, install the sample holder with the substrate on the rotatable sample holder, close the sputtering chamber, and evacuate to 1×10 -4 Pa.

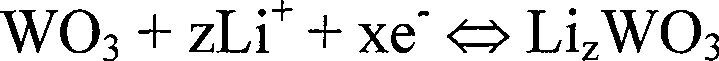

[0095] (3) Deposition of WO 3 film

[0096] Ar and O are introduced into the vacuum coating chamber through a mass flow meter 2 , adjust various parameters, pre-sputter for 30 minutes, cool the substrate with liquid nitrogen, make the substrate temperature about -120°C, and then start to deposit WO on the ITO substrate 3 Thin film, described c...

Embodiment 2

[0138] (1) Preparation of the substrate

[0139] The purchased ITO conductive glass was cut into 2×3cm substrates, and the cut substrates were ultrasonically cleaned in acetone for 2.5 hours, then ultrasonically cleaned with absolute ethanol for 2.5 hours, and finally cleaned in deionized water for 2.5 hours to obtain Spare ITO glass substrates. Mount the substrate on a sample holder for multi-target magnetron sputtering.

[0140] (2) vacuuming

[0141] Open the sputtering film forming chamber, install the sample holder with the substrate on the rotatable sample holder, close the sputtering chamber, and evacuate to 1×10 -4 Pa.

[0142] (3) Deposition of WO 3 film

[0143] Ar and O are introduced into the vacuum coating chamber through a mass flow meter 2 , adjust various parameters, pre-sputter for 30 minutes, cool the substrate with liquid nitrogen, make the substrate temperature about -130°C, and then start to deposit WO on the ITO substrate 3 Thin film, described con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com