A kind of laser self-mixing interferometric measurement device and measurement method

A self-mixing interference and measurement device technology, applied in the field of optical sensing, can solve the problems of expensive output light polarization of electro-optic modulators, small continuous wavelength modulation range, strong fluctuation of output light, etc., and achieve high interference phase detection accuracy, modulation Large scope, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

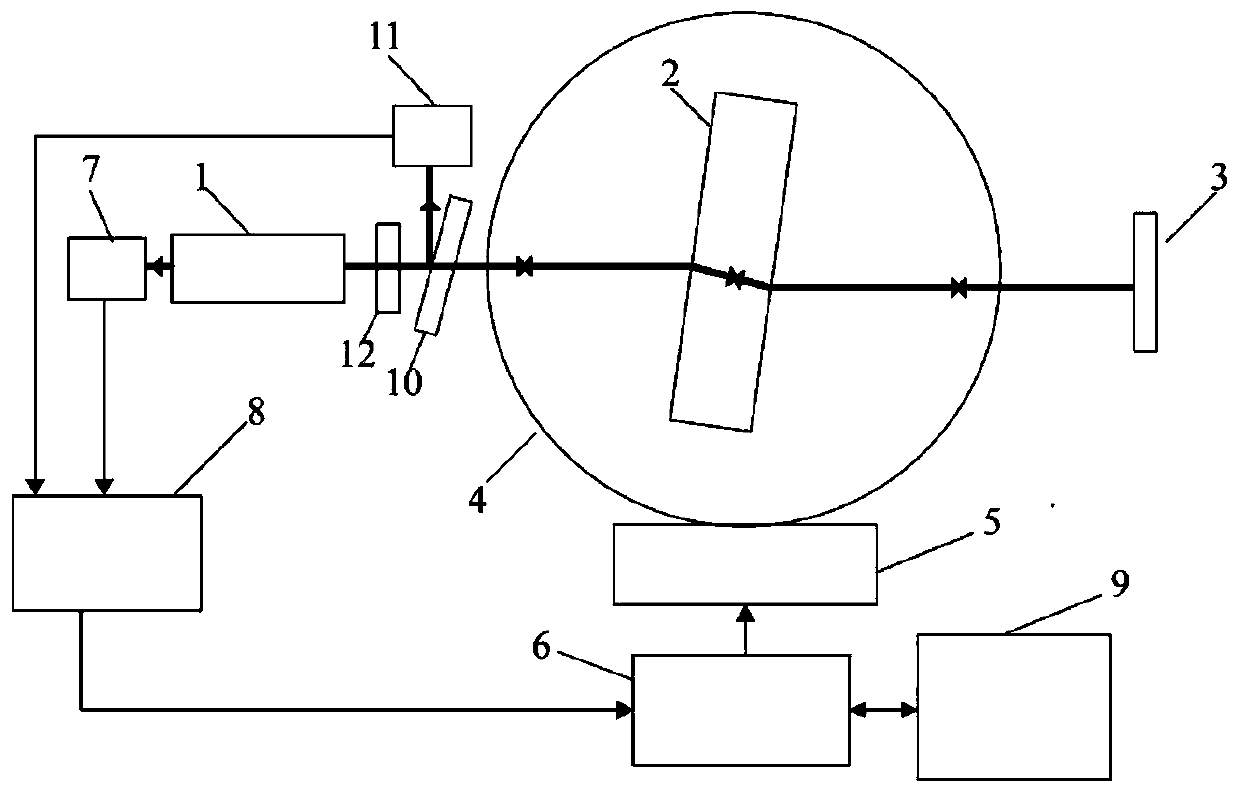

[0033] A laser self-mixing interferometry device, comprising a laser 1, a parallel flat crystal 2, a target reflector 3, a rotating platform 4, two intensity-type photodetectors (the first photodetector 7 and the second photodetector 11), Half mirror 10, attenuation sheet 12 and corresponding drive and control circuit.

[0034] The front end of the resonant cavity of the laser 1 emits a laser beam, and the laser beam enters the parallel flat crystal 2, exits from the parallel flat crystal 2, is vertically incident on the target reflector 3, and is reflected by the target reflector 3 to form a feedback beam. The feedback beam returns to the resonant cavity of the laser 1 according to the original path, and the feedback beam and the beam in the resonant cavity form self-mixing interference (adjust the attenuation plate 12 to make the interference in a weak feedback state); after the first photodetector 7 detects the resonant cavity of the laser 1 end output light intensity (or p...

Embodiment 2

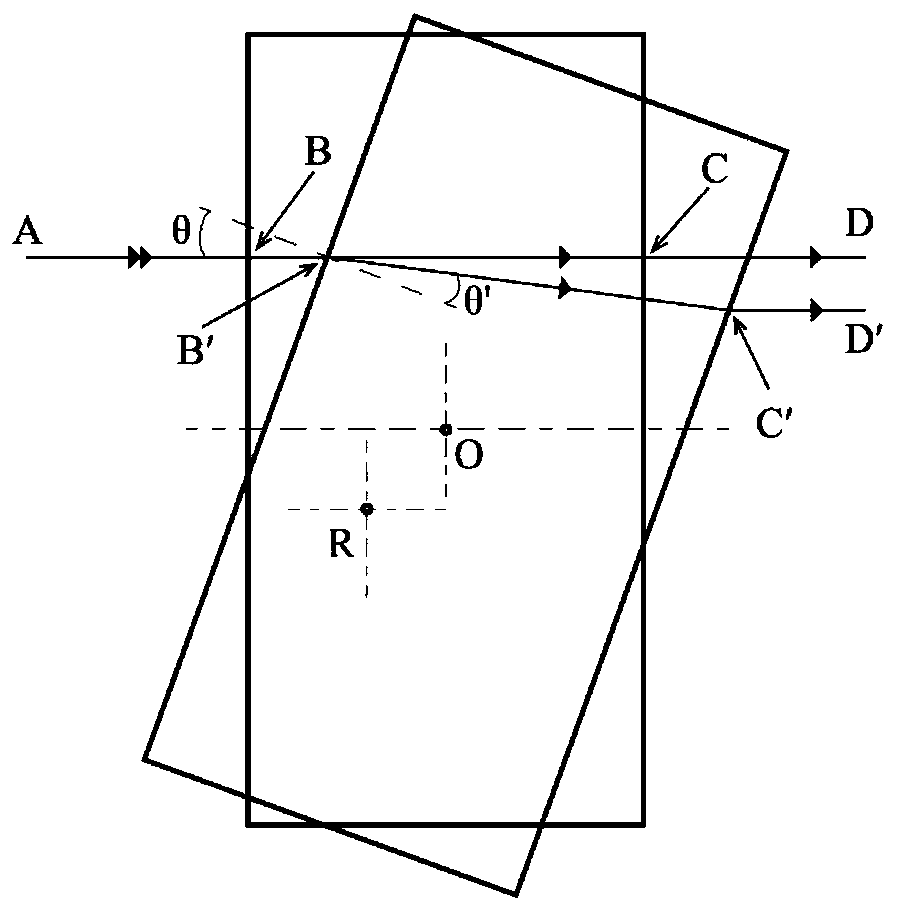

[0039] A method for measuring the micro-displacement of a target reflector using the device of Embodiment 1. First, adjust the above-mentioned optical path so that the laser beam output by the laser 1 is vertically incident on the target reflector 3 through the parallel flat crystal 2, and then passes through the target reflector. 3. The reflection is fed back to the laser cavity of laser 1 according to the original path, forming interference with the laser in the cavity (adjust the attenuation plate 12 to make the interference weak feedback). Then, record the initial position (0°) when the laser beam is vertically incident on the surface of the flat crystal 2, and the rotary table controller 5 drives the rotary platform 4 to rotate within the range of ±90°, changing the optical path of the laser beam inside and outside the parallel flat crystal 2 , to realize the modulation of the self-mixing interference signal, receive the self-mixing interference signal with the photodetect...

Embodiment 3

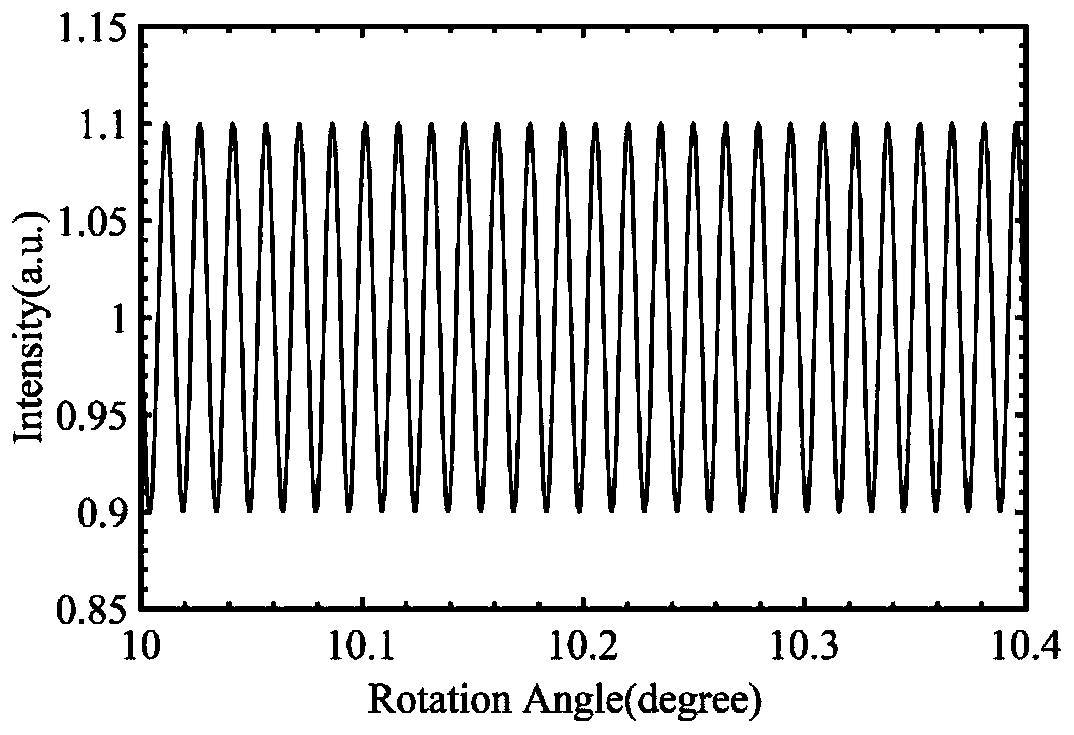

[0049] figure 1 It is a schematic structural diagram of the laser self-mixing interferometry device disclosed in this embodiment. Laser 1 is a helium-neon laser with an output power of 0.5mW and a wavelength of λ=632.8nm. The parallel flat crystal 2 is a K9 glass flat crystal with a refractive index of 1.5163 and a thickness of 20mm. The target reflector 3 is a plane mirror. After turning on the laser 1 and the computer 9, adjust the optical path so that the laser beam output by the laser 1 is incident on the reflector through the flat crystal, and then reflected by the reflector and fed back to the laser cavity according to the original path to form interference with the laser in the cavity (adjust the attenuation sheet 12, making the interference a weak feedback); then, use the rotating platform 4 to carry the flat crystal 2 to do the rotating motion, and modulate the self-mixing interference signal; use a loudspeaker with a power of 0.25W to carry the target reflector 3, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com