Preparation method of low moisture lithium tetrafluoroborate

A technology of lithium tetrafluoroborate and hydrated lithium metaborate, which is applied in the directions of tetrafluoroboric acid, borates, boron oxide compounds, etc., can solve the problems of being unsuitable for industrial production, increasing production costs, complicated operations, etc., and shortening the drying time. , the effect of reducing energy consumption and simple process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

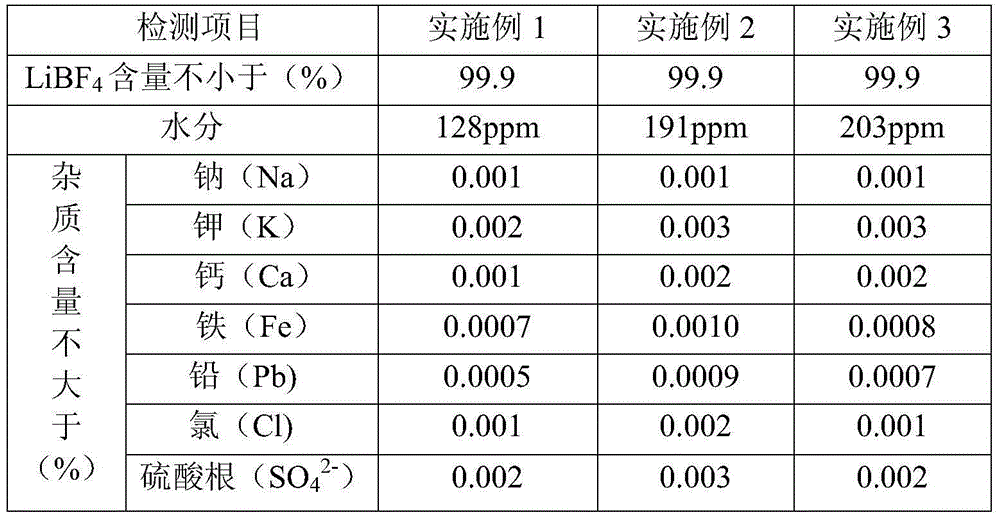

Examples

Embodiment 1

[0022] A preparation method of low-moisture lithium tetrafluoroborate, the steps are as follows:

[0023] 1) Weigh 86.1g of lithium metaborate dihydrate and dissolve it in 86.2g of pure water, and stir fully to obtain a lithium metaborate slurry;

[0024] 2) Slowly add the above slurry into a polytetrafluoroethylene reactor filled with 200.4g of 40% hydrofluoric acid for reaction and fully stir to obtain a crude solution of lithium tetrafluoroborate, and the reaction time is 1h;

[0025] 3) Slowly add boric acid to the above solution, and fully stir until the reaction is complete to obtain a clear lithium tetrafluoroborate solution, consuming 27.8g of boric acid, and the reaction time is 1h;

[0026] 4) Filter the above clarified lithium tetrafluoroborate solution, concentrate it in a water bath at 80°C until the content of lithium tetrafluoroborate is 55%, then adjust the temperature of the water bath to 30°C, and centrifuge to obtain lithium tetrafluoroborate after the cryst...

Embodiment 2

[0030] A preparation method of low-moisture lithium tetrafluoroborate, the steps are as follows:

[0031] 1) Weigh 172.0g of lithium metaborate dihydrate and dissolve it in 258.4g of pure water, and stir fully to obtain a lithium metaborate slurry;

[0032] 2) Slowly add the above slurry into a polytetrafluoroethylene reactor filled with 410.5g of 40% hydrofluoric acid for reaction and fully stir to obtain a crude solution of lithium tetrafluoroborate, and the reaction time is 1.5h;

[0033] 3) Boric acid was slowly added to the above solution, and fully stirred until the reaction was complete to obtain a clear lithium tetrafluoroborate solution, 59.6 g of boric acid was consumed, and the reaction time was 1.5 h;

[0034] 4) Filter the above-mentioned lithium tetrafluoroborate clarified solution, concentrate it in a water bath at 90°C until the content of lithium tetrafluoroborate is 65%, then adjust the temperature of the water bath to 35°C, and centrifuge to obtain lithium t...

Embodiment 3

[0038] A preparation method of low-moisture lithium tetrafluoroborate, the steps are as follows:

[0039] 1) Weigh 258.0g of lithium metaborate dihydrate and dissolve it in 516.3g of pure water, and fully stir to obtain a lithium metaborate slurry;

[0040] 2) Slowly add the above slurry into a polytetrafluoroethylene reactor filled with 631.2g of 40% hydrofluoric acid for reaction and fully stir to obtain a crude solution of lithium tetrafluoroborate, and the reaction time is 2h;

[0041] 3) Boric acid was slowly added to the above solution, and fully stirred until the reaction was complete to obtain a clear lithium tetrafluoroborate solution, 90.1 g of boric acid was consumed, and the reaction time was 2 hours;

[0042] 4) Filter the above-mentioned lithium tetrafluoroborate clarified solution, concentrate it in a water bath at 90°C until the content of lithium tetrafluoroborate is 75%, then adjust the temperature of the water bath to 40°C, and centrifuge to obtain lithium t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com