The preparation method of methyl tin maleate

A technology of methyl tin acid and maleic acid, which is applied in the field of preparation of methyl tin maleate, can solve the problems of poor compatibility between maleic anhydride and solvents, difficulty in judging the end point of the reaction, long reaction cycle, etc. The effect of shortening, avoiding wall-adhering paste, and short reaction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

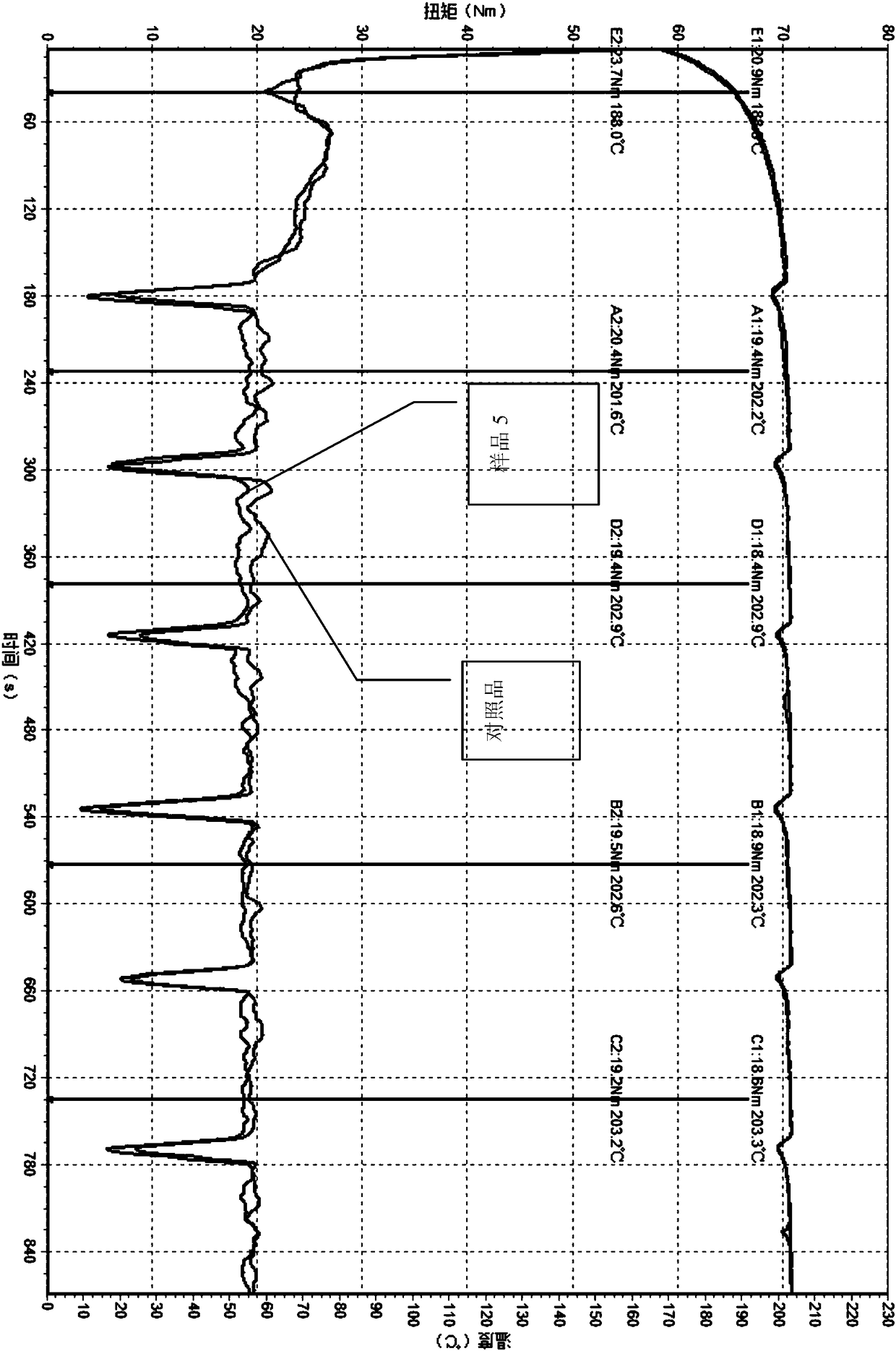

[0034] The preparation method of embodiment 1 methyl tin maleate

[0035] Add 0.250L of an aqueous solution of monomethyl tin trichloride compound with a chloride ion concentration of 5.60mol / L to a 500ml three-necked flask, stir, heat to 50°C, start the dropwise addition of liquid caustic soda reaction, control the dripping speed of liquid caustic soda to 5ml / min, control The reaction temperature is 55-75°C, and the pH value of the reaction system is adjusted to 7.5 as the end point of the reaction. Insulate and react for 30 minutes, cool, and the product is filtered through a plate and frame filter press, washed with water, and squeezed (pressing pressure reaches more than 10 MPa) to obtain a wet product methyl tin oxide (tin content is about 40%-50%).

[0036] After the above-mentioned methyl tin oxide was simply crushed, it was fed into a stirred 1000ml three-necked flask filled with 600ml of n-hexane, and 0.707mol of maleic acid was added. Set up a water separator on the...

Embodiment 2

[0038] The preparation method of embodiment 2 methyl tin maleate

[0039] Add 0.250L of an aqueous solution of monomethyl tin trichloride compound with a chloride ion concentration of 6.00mol / L to a 500ml three-necked flask, stir, heat to 55°C, start dropwise addition of liquid caustic soda reaction, control the liquid caustic soda dropping rate to 9ml / min, and control The reaction temperature is 60-80°C, and the pH value of the reaction system is adjusted to 8.0 as the end point of the reaction. Insulate and react for 50 minutes, cool, and the product is filtered through a plate and frame filter press, washed with water, and squeezed (pressing pressure reaches above 10MPa) to obtain a wet product methyl tin oxide (tin content is about 40%-50%).

[0040] After the above-mentioned methyl tin oxide was simply crushed, it was fed into a stirred 1000ml three-neck flask filled with -650ml of n-hexane, and 0.78mol of maleic acid was added. Set up a water separator on the reactor, c...

Embodiment 3

[0042] The preparation method of embodiment 3 methyl tin maleate

[0043] Add 0.200L of an aqueous solution of dimethyl tin dichloride compound with a chloride ion concentration of 6.50mol / L to a 500ml three-necked flask, stir, heat to 68°C, start dropwise addition of liquid caustic soda reaction, control the dripping speed of liquid caustic soda to 7ml / min, and control The reaction temperature is 60-85°C, and the pH value of the reaction system is adjusted to 8.2 as the end point of the reaction. Heat preservation reaction for 45 minutes, cool, and the product is filtered through a plate and frame filter press, washed with water, and squeezed (pressing pressure reaches above 10MPa) to obtain the wet product methyl tin oxide (tin content is about 40%-50%).

[0044] After the above-mentioned methyl tin oxide was simply crushed, it was fed into a stirring 1000ml three-necked flask containing 650ml of n-hexane, and 0.66mol of maleic acid was added. Set up a water separator on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com