Low-position few-fulcrum modularized integral jacking steel platform formwork system

An overall jacking and steel platform technology, applied in the field preparation of formwork/formwork/working frame, building components, construction, etc., can solve the problems of non-standardized operation, non-returnable use, high erection cost, etc., to achieve The effects of standardization, lower project cost, and lower construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

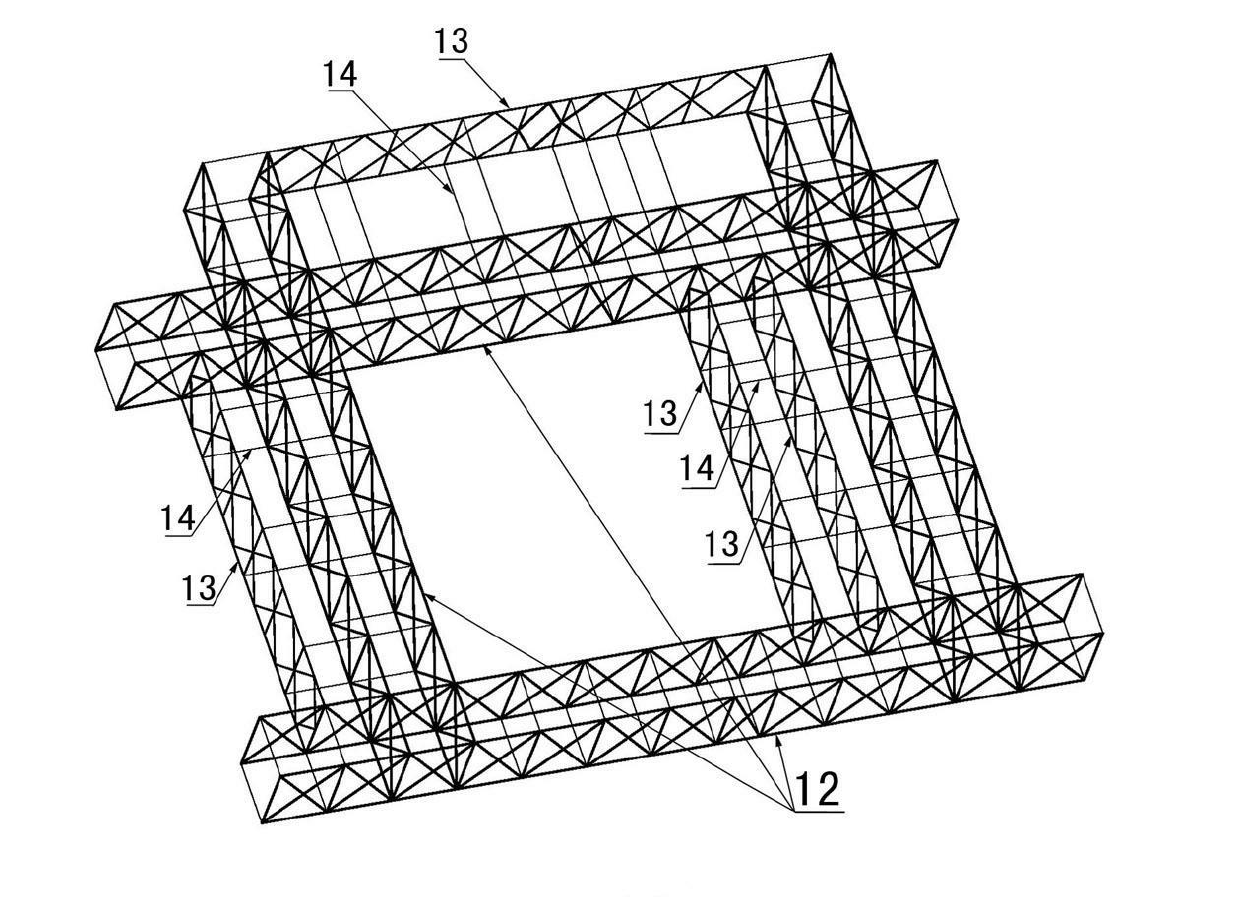

[0065] Examples see figure 1 As shown, this low-position and less-fulcrum modular overall jacking steel platform formwork system includes the low-position jacking formwork system jacking device supported on the core tube shear wall 8, which is connected to the low-level jacking system through the support column 3. The steel platform 1 on the jacking device of the formwork system, and the hanger 2 and the formwork 7 suspended on the steel platform 1, in this embodiment, the formwork 7 is a shaped large steel formwork. The entire low-level and less-fulcrum modular overall jacking steel platform formwork system often requires three or four sets of low-level jacking formwork system jacking devices.

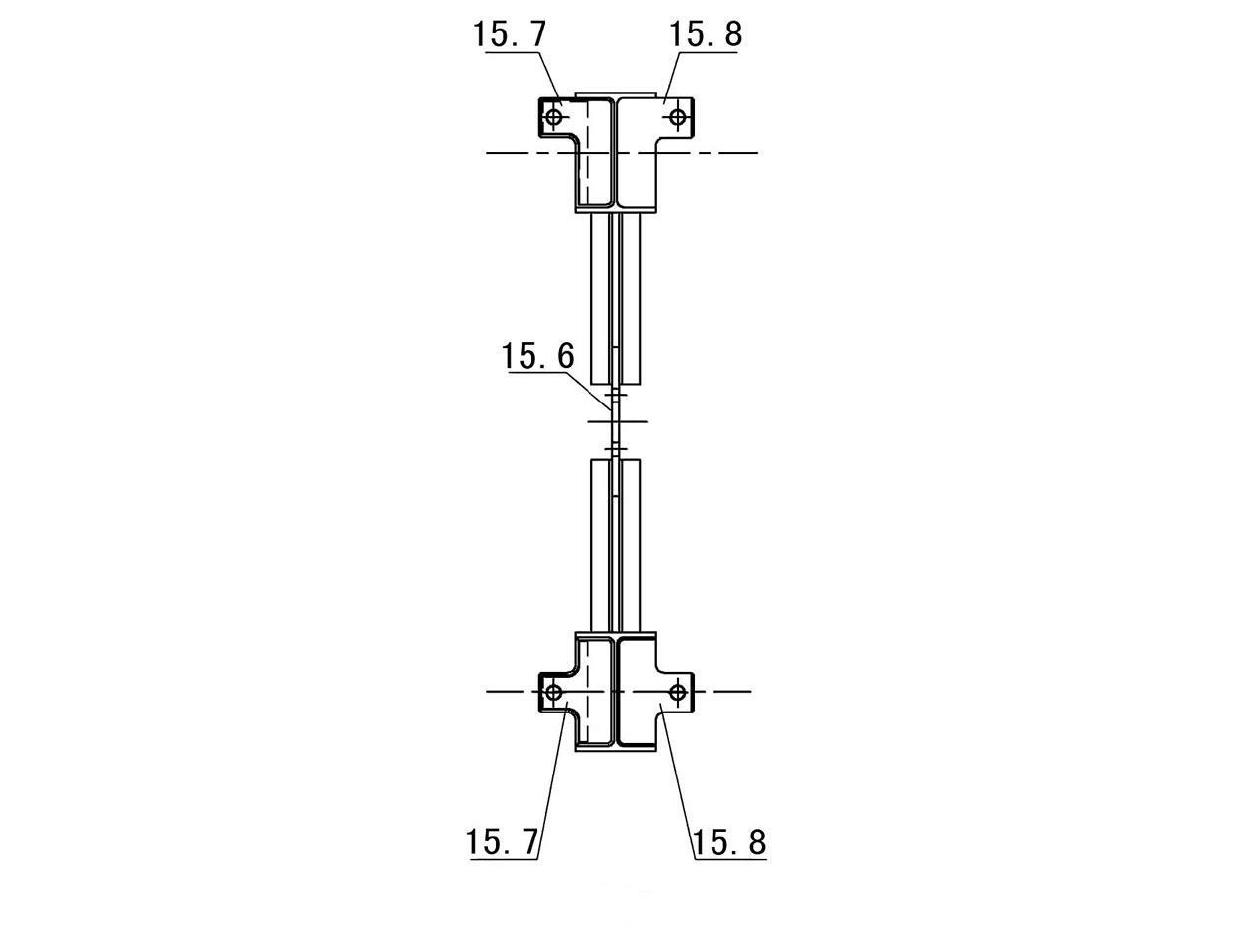

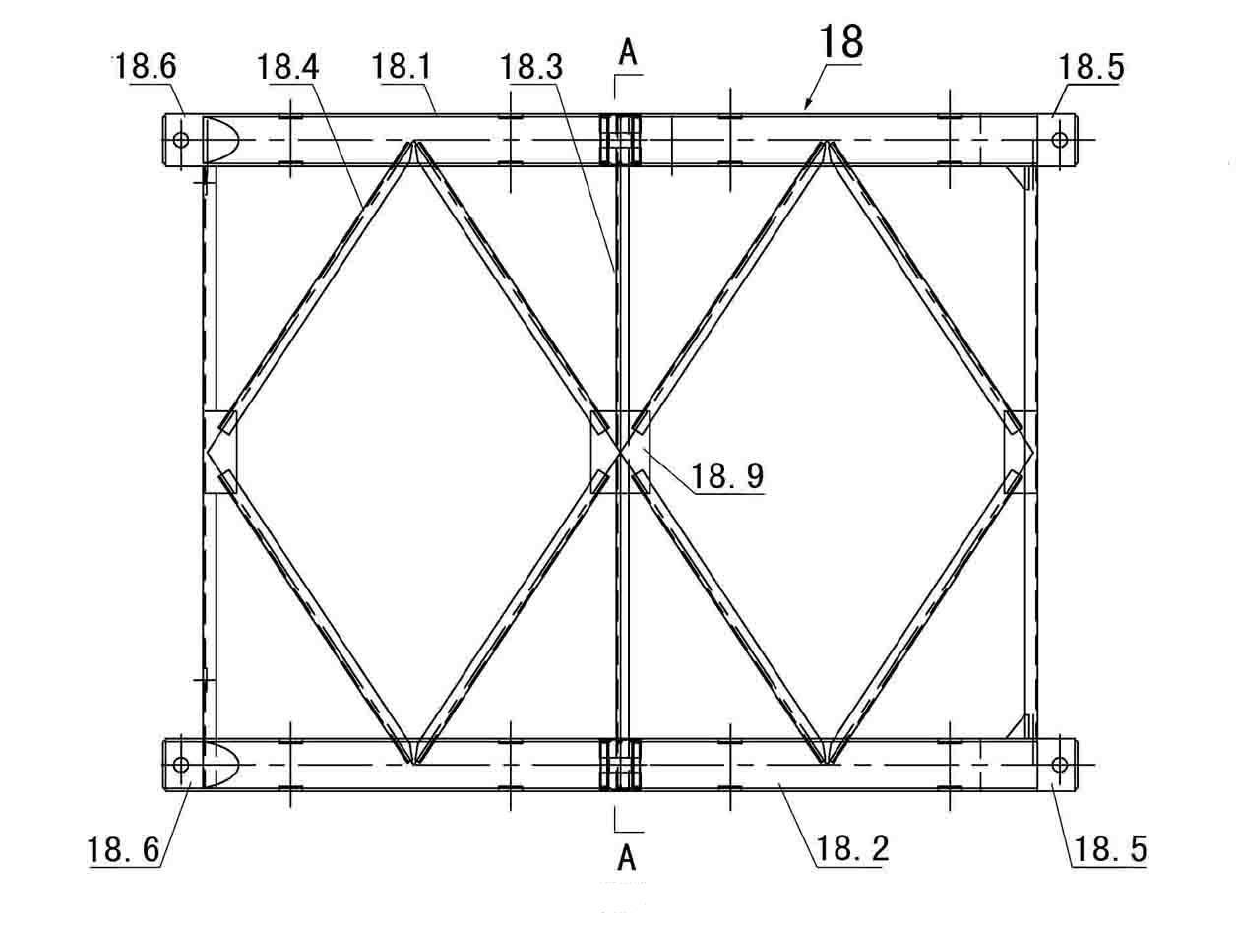

[0066] see Figure 18-20 , the supporting column 3 is a standardized lattice column, including an upper pad beam 31 connected with the steel platform 1, a lower pad beam 32 connected with the upper support beam 5, and connected between the upper pad beam 9 and the lower pad beam 32 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com