High-temperature alloy for hydrogen fuel cell air compressor bearing, and preparation method thereof

A superalloy and fuel cell technology, applied in IPC classification C22C38/00 iron-based alloys, superalloys for hydrogen fuel cell air compressor bearings and their preparation fields, can solve difficult air compressor bearing parts, alloy strength reduction, microstructure Complex structure and other problems, to achieve the effect of control and cost, Fe content improvement, excellent processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] Among the present invention, the preparation method step of superalloy is:

[0044] Step 1: The above components are cast into master alloy ingots by vacuum induction melting, and then cast into alloy ingots by vacuum consumable melting process;

[0045] Step 2: Homogenize the alloy ingot in stages at 1150°C to 1200°C for more than 25 hours;

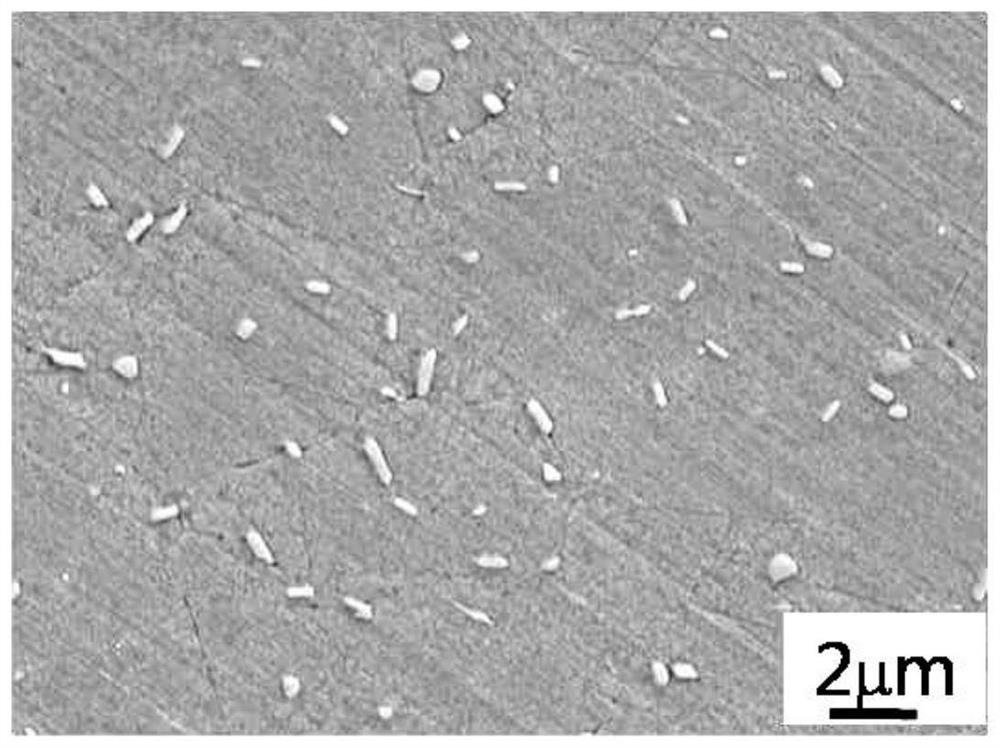

[0046] Step 3: Forging the homogenized master alloy ingot at 950°C to 1130°C to form a rod;

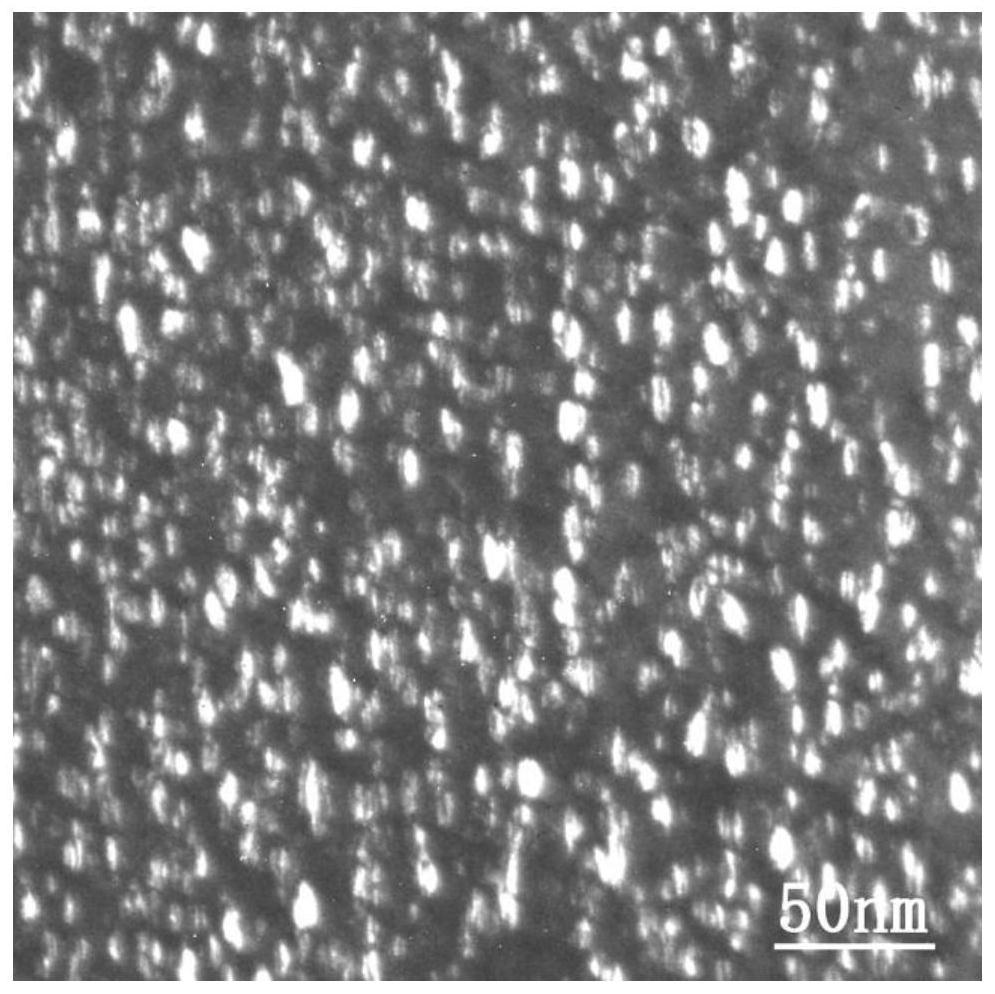

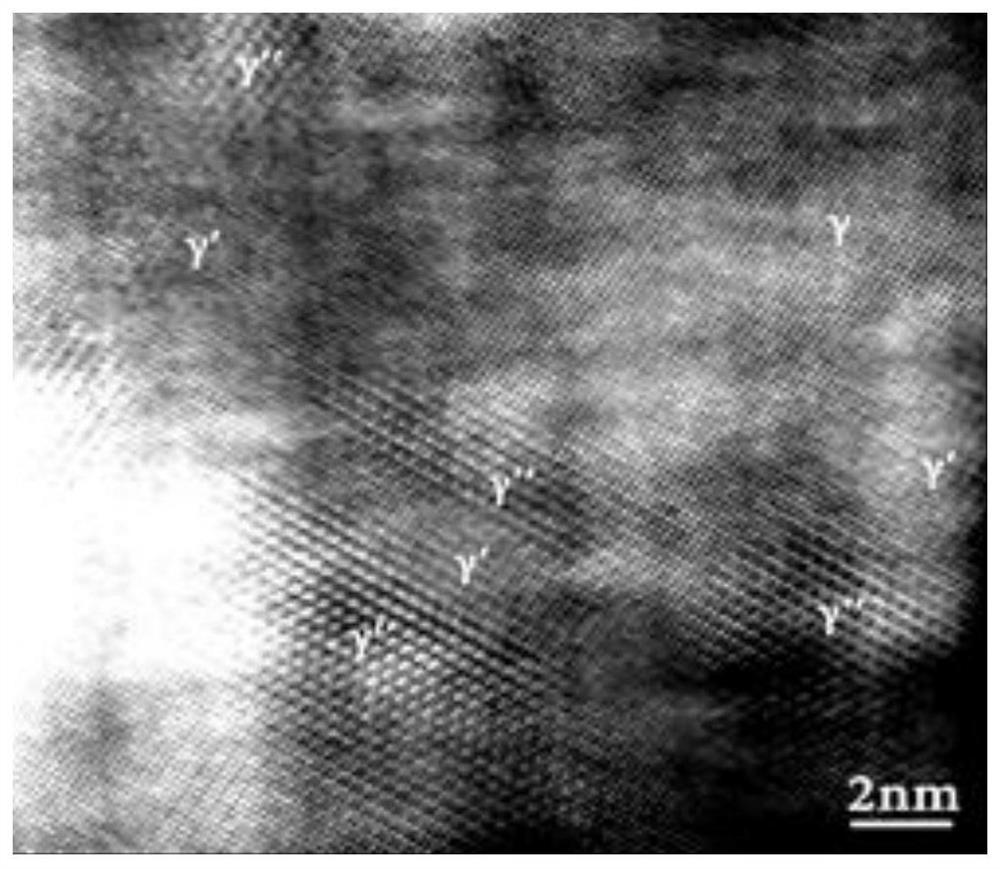

[0047] Step 4: Perform mechanical treatment on the surface of the rod to make the grain size on the surface of the rod less than 0.1 μm, further improving the room temperature strength and surface quality of the alloy.

[0048] In the present invention, the superalloy has the advantages of low cost, high strength from room temperature to high temperature, and excellent processing performance, and can be made into rods of different sizes, which are used to prepare bearings, the core component of oil-free air compressors. Further, the man...

Embodiment 1

[0051] Example 1: The composition by weight is: C 0.07%, Fe 18%, Cr 18%, Al 1.5%, Ti 2.2%, Nb 5%, Mo 5%, B 0.05%, Si 0.13%, Mn 0.08%, balance For you.

Embodiment 2

[0052] Embodiment 2: The weight ratio composition is: C 0.02%, Fe 10%, Cr 12.5%, Al 0.9%, Ti 1.2%, Nb3.6%, Mo 2.5%, B 0.03%, Si 0.10%, Mn 0.09%, The balance is Ni.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com