Lithium Hydroxide Recovery Technology from Solution by Bipolar Membrane Method

A technology of lithium hydroxide and bipolar membranes, applied in electrolysis process, electrolysis components, etc., can solve the problems of long production process, high operation cost, environmental pollution, etc., reduce production operation cost, reduce production cost, no secondary The effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Lithium sulfate solution is mainly derived from the by-products produced in the production of lithium iron sulfate batteries, with a concentration ranging from 5-20%. Mainly contains lithium sulfate and some Fe 3+ , enter the system for processing.

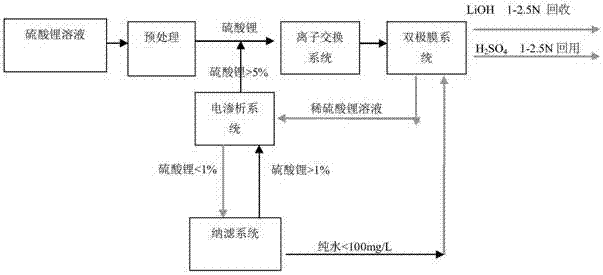

[0024] With reference to the accompanying drawings, the lithium sulfate solution entering the process of the present invention is first processed in step (1): the lithium sulfate solution is treated with an ultrafiltration system and ion exchange, mainly to remove divalent and more than divalent metal ions; after pretreatment Finally, the parameters of the purified lithium sulfate solution are as follows: control iron ions below 1mg / l, calcium and magnesium ions below 1mg / l, COD below 5mg / l, bicarbonate below 20mg / l, silicon dioxide If it is lower than 5mg / l, the concentration of lithium sulfate is 5-20% (mass percentage), the water produced in the pretreatment system enters the treatment of step (2), and the concentrated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com