High Fe content Al-Mg2Si alloy prepared by laser selective melting and preparation method

A technology of laser selective melting and alloying, which is applied in the direction of improving process efficiency, additive manufacturing, and improving energy efficiency. It can solve problems such as high cost and difficulty in promotion, and achieve the effects of eliminating harmful effects, good strengthening effects, and excellent mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

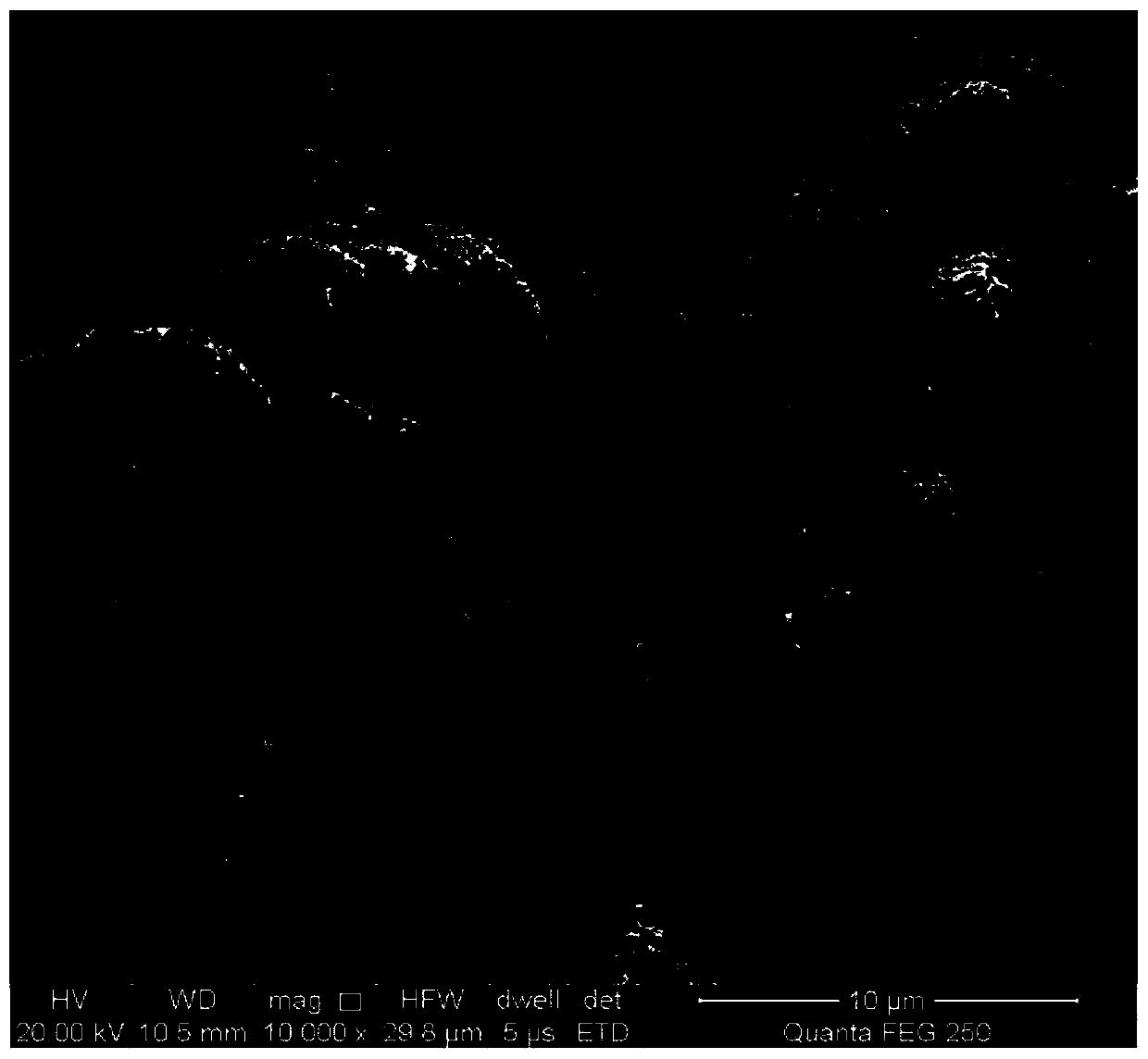

Image

Examples

Embodiment 1

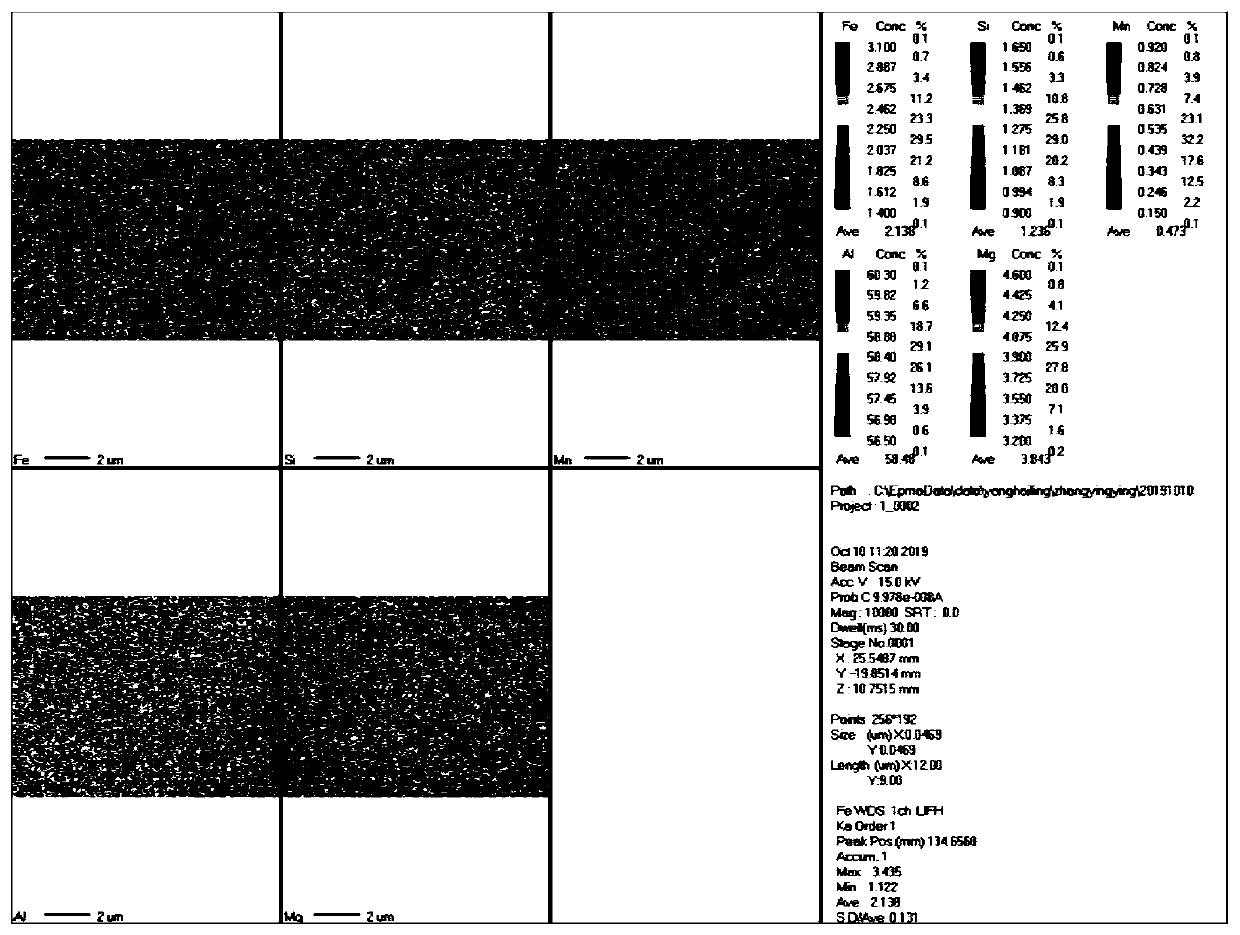

[0067] 1. Composition and content of aluminum alloy composition

[0068] A1-89.7% Mg-5.5% Si-2.2% Mn-0.6% Fe-2%

[0069] 2. Preparation steps of aluminum alloy forming parts

[0070] 1) Provide the sieved Al-Mg Si gas atomized spherical powder;

[0071] 2) Use slicing software to slice the CAD model of the part to obtain the two-dimensional data of each layer, and then transmit the data to the SLM device;

[0072] 3) Spread 0.05mm of Al-Mg provided in step 1) on a detachable aluminum alloy substrate preheated to 100°C 2 Si alloy powder;

[0073] 4) Laser scanning step 3) The geometric shape of the cross-section of the metal powder layer. During the scanning process, the laser spot is 0.1mm, the laser power is 310W, and the laser scanning rate is 800mm / s to make it melt and solidify. Under the condition of Ar atmosphere;

[0074] 5) The piston of the forming cylinder is lowered by one powder layer thickness, the scraper runs to spread the second layer of powder evenly, and...

Embodiment 2

[0079] 1. Composition and content of aluminum alloy composition

[0080] A1-89.7% Mg-5.5% Si-2.2% Mn-0.6% Fe-2%

[0081] 2. Preparation steps of aluminum alloy forming parts

[0082] 1) Provide the sieved Al-Mg Si gas atomized spherical powder;

[0083] 2) Use slicing software to slice the CAD model of the part to obtain the two-dimensional data of each layer, and then transmit the data to the SLM device;

[0084] 3) Spread 0.05mm of the Al-Mg2Si alloy powder provided in step 1) on a detachable aluminum alloy substrate preheated to 100°C;

[0085] 4) Laser scanning step 3) The geometric shape of the cross-section of the metal powder layer. During the scanning process, the laser spot is 0.1mm, the laser power is 310W, and the laser scanning rate is 800mm / s to make it melt and solidify. Under the condition of Ar atmosphere;

[0086] 5) The piston of the forming cylinder is lowered by one powder layer thickness, the scraper runs to spread the second layer of powder evenly, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com