Precipitation-strengthening type AlCrFeNiV system high-entropy alloy and preparation method thereof

A high-entropy alloy, precipitation strengthening technology, applied in the field of metal materials, can solve the problem of low high-entropy alloy, achieve high strength and improve the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

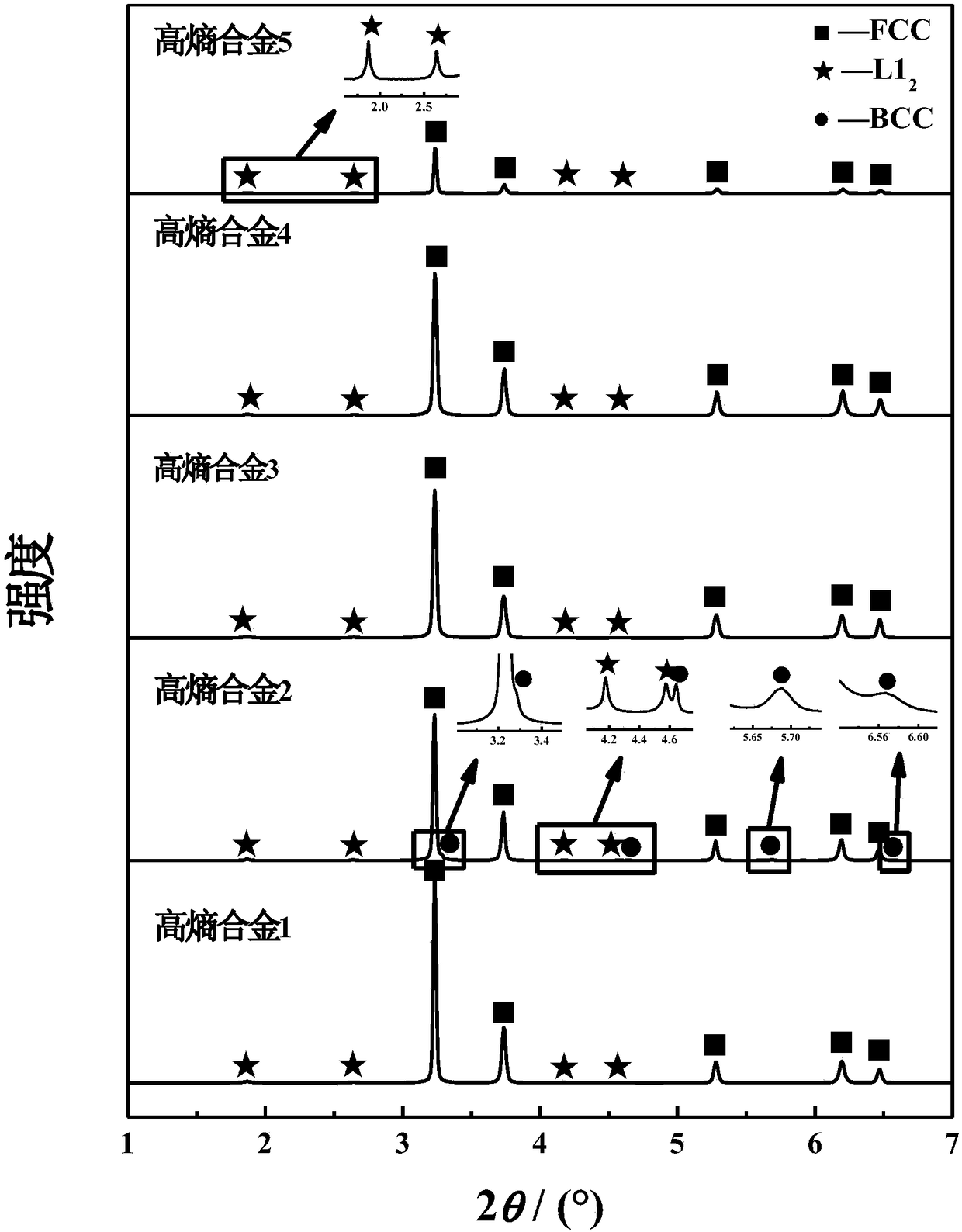

Embodiment 1

[0034] al 0.38 Cr 0.69 Fe 0.6 Ni 2.12 V 0.17 The specific preparation steps of high-entropy alloy (hereinafter referred to as high-entropy alloy 1) are as follows:

[0035] (1) Ingredients: Use sandpaper and grinder to remove impurities such as Al, Cr, Fe, Ni and V surface oxide scales, and then use acetone and absolute ethanol for ultrasonic cleaning to obtain clean metal elements; according to the measurement in the chemical formula Ratio, accurately weigh Al, Cr, Fe, Ni and V, the total mass of raw materials is 80g;

[0036] (2) Smelting: stack the clean metal elements from bottom to top in the order of melting point from low to high in the water-cooled copper crucible of the high-vacuum non-consumable arc melting furnace, and then vacuumize until the vacuum degree in the melting furnace up to 2.5×10 -3 Pa, and then filled with high-purity argon as a protective gas; first smelt pure Ti metal ingots to further reduce the oxygen content in the smelting furnace cavity, a...

Embodiment 2

[0043] al 0.6 Cr 0.84 Fe 1.2 Ni 3 V 0.24 The specific preparation steps of high-entropy alloy (hereinafter referred to as high-entropy alloy 2) are as follows:

[0044] (1) Ingredients: Use sandpaper and grinder to remove impurities such as Al, Cr, Fe, Ni and V surface oxide scales, and then use acetone and absolute ethanol for ultrasonic cleaning to obtain clean metal elements; according to the measurement in the chemical formula Ratio, accurately weigh Al, Cr, Fe, Ni and V, the total mass of raw materials is 80g;

[0045] (2) Smelting: stack the clean metal elements from bottom to top in the order of melting point from low to high in the water-cooled copper crucible of the high-vacuum non-consumable arc melting furnace, and then vacuumize until the vacuum degree in the melting furnace up to 2.5×10 -3 Pa, and then filled with high-purity argon as a protective gas; first smelt pure Ti metal ingots to further reduce the oxygen content in the smelting furnace cavity, and t...

Embodiment 3

[0052] al 0.5 Cr 0.55 FeNi 2.5 V 0.2 The specific preparation steps of high-entropy alloy (hereinafter referred to as high-entropy alloy 3) are as follows:

[0053] (1) Ingredients: Use sandpaper and grinder to remove impurities such as Al, Cr, Fe, Ni and V surface oxide scales, and then use acetone and absolute ethanol for ultrasonic cleaning to obtain clean metal elements; according to the measurement in the chemical formula Ratio, accurately weigh Al, Cr, Fe, Ni and V, the total mass of raw materials is 80g;

[0054] (2) Smelting: stack the clean metal elements from bottom to top in the order of melting point from low to high in the water-cooled copper crucible of the high-vacuum non-consumable arc melting furnace, and then vacuumize until the vacuum degree in the melting furnace up to 2.5×10 -3 Pa, and then filled with high-purity argon as a protective gas; first smelt pure Ti metal ingots to further reduce the oxygen content in the smelting furnace cavity, and then c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com