Super-strong high-plastic titanium alloy and preparation method thereof

A technology of titanium alloy and high plasticity, applied in the field of super-strength and high-plastic titanium alloy and its preparation, can solve problems such as the inability to meet the needs of aircraft design and parts processing and manufacturing, so as to solve metallurgical problems, reduce smelting segregation, and improve material strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

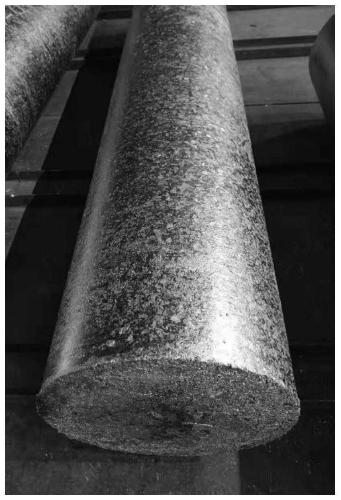

Examples

Embodiment 1

[0040] A method for preparing a super-strong high-plastic titanium alloy, comprising the following steps:

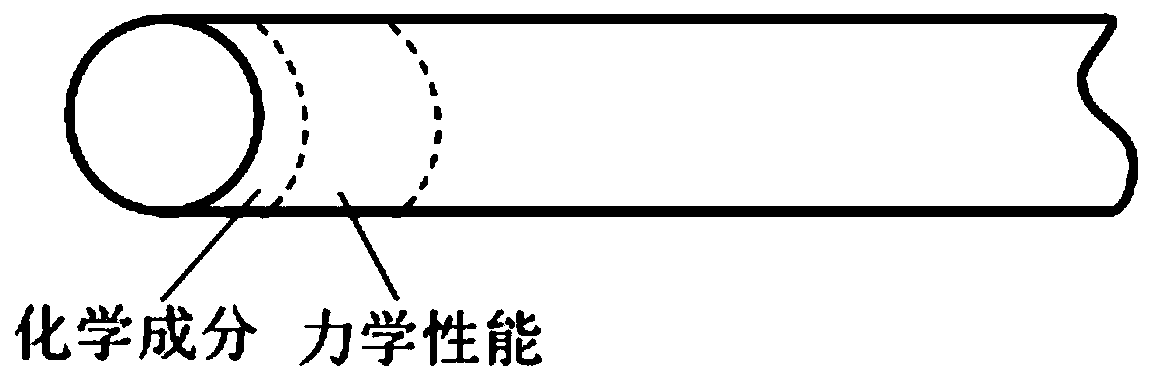

[0041] Step 1: Electrode preparation.

[0042] Select a quaternary alloy with a ratio of Al-Mo-Fe-Cr of 5.5:4.3:2.1:0.8, and the weight percentage ratio of each element in the electrode is: Al: 5.5%, Mo: 4.3%, Zr: 4.0%, Fe: 2.1% , Sn: 1.0%, Cr: 0.8%, O: 0.10%, the balance is Ti and trace impurities, impurity elements are less than 0.40% of the total weight. Take granular Al-Mo-Fe-Cr alloy, Ti-Sn alloy, Zr element, TiO 2 The powder and titanium sponge with a particle size of 0.83-25.4mm are mixed in proportion in the silo. The total weight of the mixture is 1t. Through continuous pressing, a monolithic electrode with a diameter of Φ400mm and no welding and a single weight of 1t is obtained.

[0043] Step 2: Ingot melting.

[0044] The vacuum consumable melting of the whole electrode was carried out three times in a vacuum consumable electric arc furnace using crucibles...

Embodiment 2

[0059] Step 1: Electrode preparation.

[0060] Select a quaternary alloy with a ratio of Al-Mo-Fe-Cr of 4.6:4.0:2.9:1.2, and the weight percentage ratio of each element in the electrode is: Al: 4.6%, Mo: 4.0%, Zr: 3.0%, Fe: 2.9% , Sn: 1.5%, Cr: 1.2%, O: 0.13%, the balance is Ti and trace impurities, impurity elements are less than 0.40% of the total weight. Take granular Al-Mo-Fe-Cr alloy, Ti-Sn alloy, Zr element, TiO 2 The powder and titanium sponge with a particle size of 0.83-25.4mm are mixed in proportion in the silo, the total weight of the mixture is 2t, and a monolithic electrode with a diameter of Φ430mm without welding and a single weight of 2t is obtained through continuous pressing.

[0061] Step 2: Ingot melting.

[0062] The overall electrode was smelted three times in a vacuum consumable electric arc furnace using crucibles with diameters of Φ560mm, Φ650mm, and Φ720mm in turn. The melting process parameters are shown in Table 4. The titanium alloy ingot is obt...

Embodiment 3

[0077] Step 1: Electrode preparation.

[0078] Select a quaternary alloy with a ratio of Al-Mo-Fe-Cr of 5.7:4.6:2.5:1.9, and the weight percentage ratio of each element in the electrode is: Al: 5.7%, Mo: 4.6%, Zr: 3.9%, Fe: 2.5% , Sn: 1.2%, Cr: 0.4%, O: 0.13%, the balance is Ti and trace impurities, impurity elements are less than 0.40% of the total weight. Take granular Al-Mo-Fe-Cr alloy, Ti-Sn alloy, Zr element, TiO 2 The powder and titanium sponge with a particle size of 0.83-25.4mm are mixed in proportion in the silo. The total weight of the mixture is 4t. Through continuous pressing, a monolithic electrode with a diameter of Φ460mm and a single weight of 4t without welding is obtained.

[0079] Step 2: Ingot melting.

[0080] The overall electrode was vacuum smelted three times in a vacuum consumable electric arc furnace using crucibles with diameters of Φ560mm, Φ650mm, and Φ720mm in turn. The melting process parameters are shown in Table 7. The titanium alloy ingot is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com