Novel biomass-based catalyst as well as preparation method thereof and application of catalyst in coal pyrolysis

A biomass and catalyst technology, applied in the field of coal dry distillation engineering, can solve the problems such as thermal depolymerization that no one has raised, and achieve the effects of good thermal stability and oxidation resistance, stable structure, and improved conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

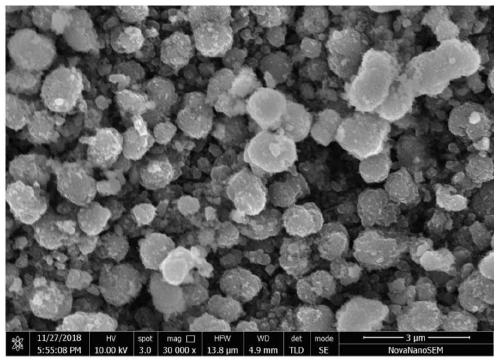

Image

Examples

Embodiment 1

[0037] A method for pyrolyzing coal using a novel bio-based catalyst, the steps are as follows:

[0038] (1) Take 1g of dehydrated lignite powder, add 4mL of swelling agent (the volume ratio of tetrahydrofuran: isopropanol is 3:1, the following examples are the same), stir for 24h in a water bath at 50°C, filter, recover the swelling agent, and collect The solid is dried to obtain swollen lignite;

[0039] (2) Take 1g of humus, carbonize it at 800°C for 1 hour, cool it and grind it into a powder below 200 meshes. Under ultrasonic conditions, disperse the powder into 100mL ethanol to obtain a humus solution; at the same time, take Ni(NO 3 ) 2 solution (100g / L, 5mL), add 0.1g of Al 2 o 3 powder, stirred in a water bath at a constant temperature of 50°C for 10 hours, dried in a constant temperature oven at 110°C to dryness to make a light green powder, and then roasted at 700°C for 2 hours to obtain a binder; Fe 2 o 3 Mix evenly with the obtained humic solution at a mass rat...

Embodiment 2

[0043] A method for pyrolyzing coal using a novel bio-based catalyst, the steps are as follows:

[0044] (1) Take 1 g of dehydrated lignite powder, add 4 mL of swelling agent, stir for 24 hours in a water bath at 50°C, filter, recover the swelling agent, collect the solid and dry to obtain swollen lignite;

[0045] (2) Take 1g of humic substance, carbonize it at 800°C for 1h, cool it and grind it into a powder below 200 mesh, and disperse the powder into 100mL ethanol under ultrasonic conditions to obtain humic acid solution; meanwhile, take Ni(NO 3 ) 2 solution (100g / L, 5mL), add 0.1g of Al 2 o 3 powder, stirred in a water bath at a constant temperature of 50°C for 10 hours, dried in a constant temperature oven at 110°C to dryness to make a light green powder, and then roasted at 700°C for 2 hours to obtain a binder; Fe 2 o 3 Mix evenly with the pretreated humic substance solution at a mass ratio of 1:3, add 0.4g of binder, then add nitric acid solution (63g / L, 3mL), mix ...

Embodiment 3

[0049] A method for pyrolyzing coal using a novel bio-based catalyst, the steps are as follows:

[0050] (1) Take 1 g of dehydrated lignite powder, add 4 mL of swelling agent, stir for 24 hours in a water bath at 50°C, filter, recover the swelling agent, collect the solid and dry to obtain swollen lignite;

[0051] (2) Take 1g of humic substance, carbonize it at 800°C for 1h, cool it and grind it into a powder below 200 mesh, and disperse the powder into 100mL ethanol under ultrasonic conditions to obtain humic acid solution; meanwhile, take Ni(NO 3 ) 2 solution (100g / L, 5mL), add 0.1g of Al 2 o 3 powder, stirred in a water bath at a constant temperature of 50°C for 10 hours, dried in a constant temperature oven at 110°C to dryness to make a light green powder, and then roasted at 700°C for 2 hours to obtain a binder; Fe 2 o 3 Mix evenly with humus solution at a mass ratio of 1:3, add 0.4g of binder, and then add nitric acid solution (63g / L, 3mL), mix evenly, extrude, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com