Super-soft aluminum alloy conductor and preparation method thereof

The technology of aluminum alloy conductor and aluminum alloy rod is applied in the field of ultra-soft aluminum alloy conductor and its preparation, and can solve the problems of large amount of wire and cable, insufficient ductility, flexibility, electrical performance and connection stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

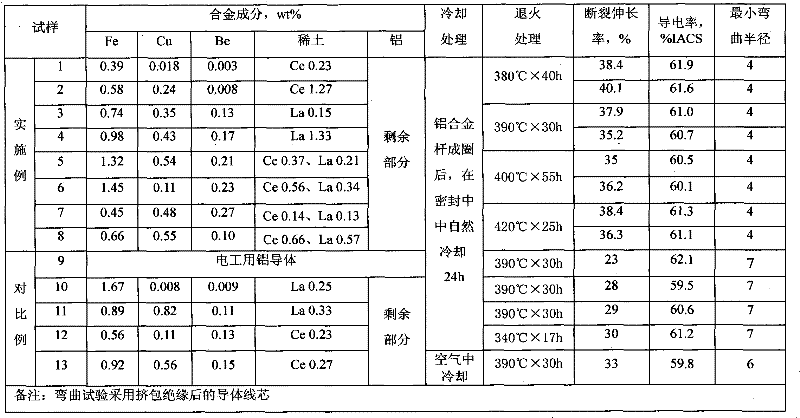

Examples

Embodiment 1

[0061] 1) 0.3-1.5wt% Fe, 0.001-0.3wt% Be, 0.005-0.6wt% Cu, 0.1-1.5wt% rare earth at 730-820°C, the rare earth element consists of at least one of Ce and La One composition, the rest is aluminum, put into the shaft furnace for smelting, after fully stirring evenly, after refining, slag removal, degassing, 740 ~ 770 ℃, after static heat preservation for 30 minutes, take samples before the furnace for analysis and adjustment to ensure the element content within the allowable range. Casting takes place in a casting machine. The cast bars are introduced into the rolling mill, the temperature of the introduction into the rolling mill is 500-550°C, and the outlet temperature is 350-420°C. Heated during hot rolling.

[0062] 2) After the aluminum alloy rod is formed into a circle, put it into a sealed heat preservation furnace or a heat preservation cover, and the rod is naturally cooled in it, and then taken out from it after 24 hours.

[0063] 3) The aluminum alloy rod is cold-dr...

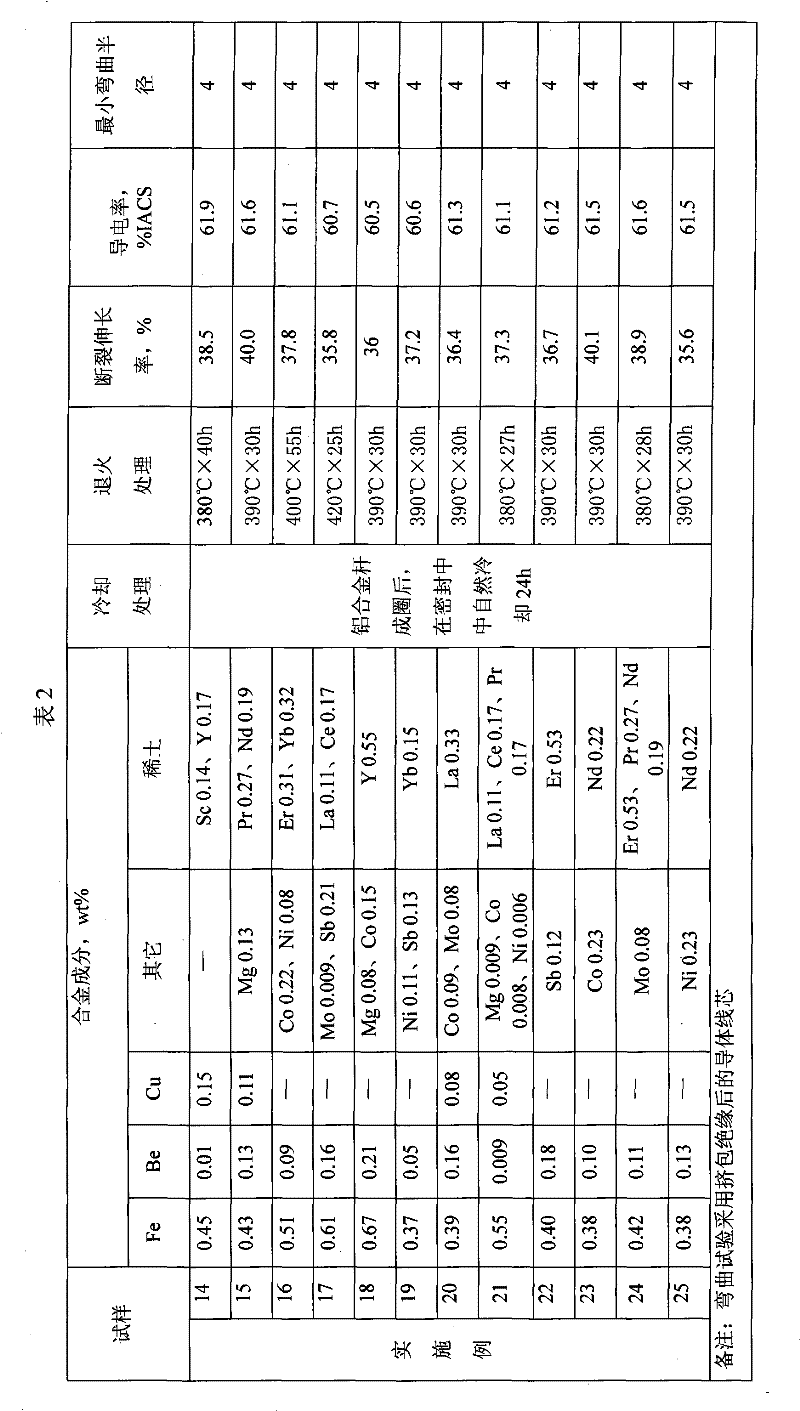

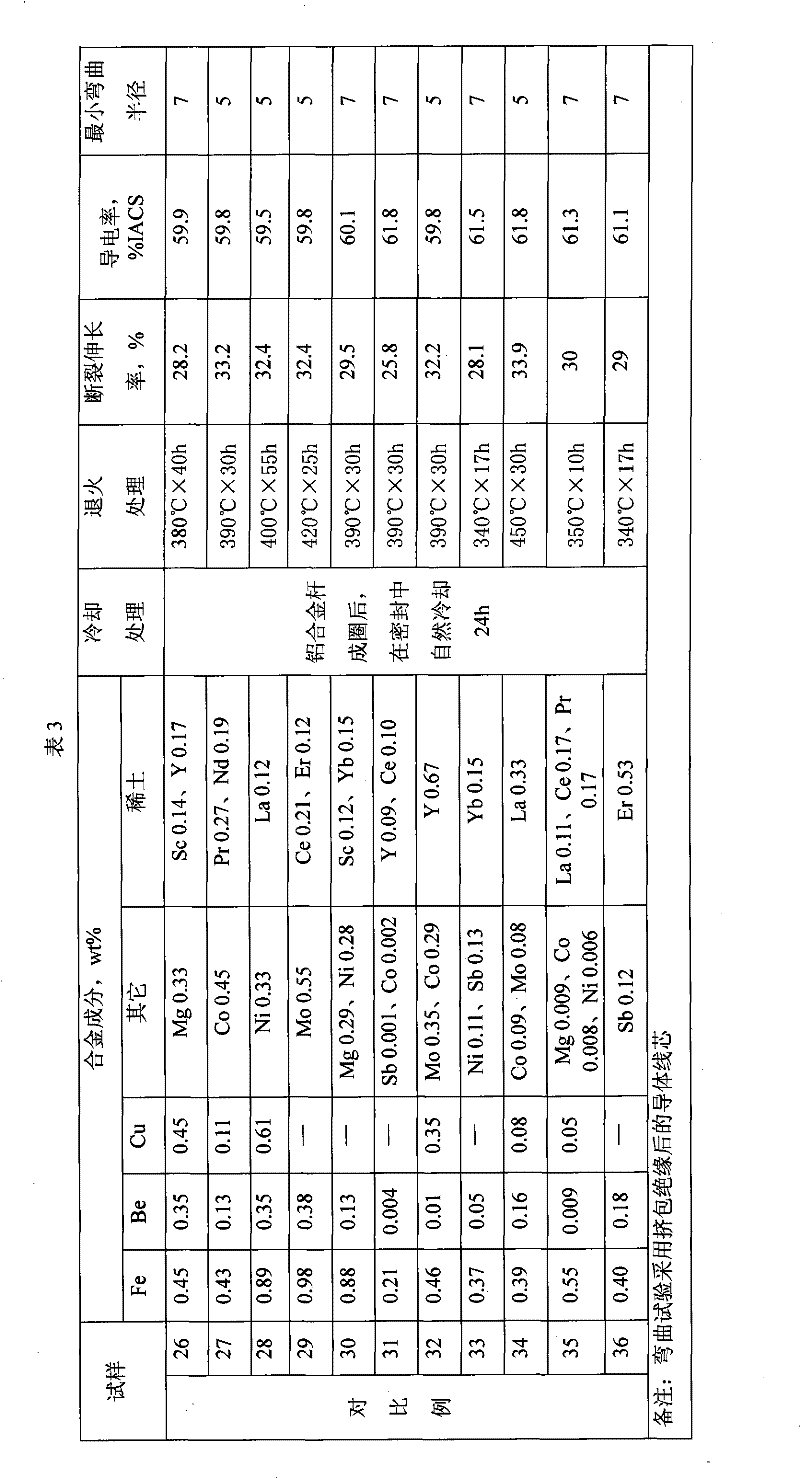

Embodiment 2

[0079] 1) Add 0.3-0.8wt% Fe, 0.001-0.3wt% Be, 0.005-0.4wt% Cu, 0.1-0.8wt% rare earth, 0.005-0.6wt% Cu at 730-820°C, and the rest are aluminum. Cu can be replaced by other elements, at least one of Mg, Cu, Co, Ni, Mo and Sb can be freely selected. The rare earth element is composed of at least one of Sc, Y, La, Ce, Pr, Nd, Er, and Yb. Put it into the shaft furnace for smelting, stir well, refine, remove slag, degas, 740 ~ 770 ℃, after static heat preservation for 30 minutes, take samples before the furnace for analysis and adjustment to ensure that the element content is within the allowable range. Casting takes place in a casting machine. The cast bars are introduced into the rolling mill, the temperature of the introduction into the rolling mill is 500-550°C, and the outlet temperature is 350-420°C. Heated during hot rolling.

[0080] 2) After the aluminum alloy rod is formed into a circle, put it into a sealed heat preservation furnace or a heat preservation cover, and t...

Embodiment 3

[0087] 1) Adding 0.3-0.8wt% Fe, 0.001-0.3wt% Be, 0.005-0.4wt% Cu, 0.1-0.8wt% rare earth and the rest aluminum at 730-820°C. Cu can be replaced by other elements, at least one of B, Ca, Ti, Cu, Zn, Ge, Sr, Zr, Nb, Ag, Sn can be freely selected. The rare earth element is composed of at least one of Sc, Y, La, Ce, Pr, Nd, Er, and Yb. Put it into the shaft furnace for smelting, stir well, refine, remove slag, degas, 740 ~ 770 ℃, after static heat preservation for 30 minutes, take samples before the furnace for analysis and adjustment to ensure that the element content is within the allowable range. Casting takes place in a casting machine. The cast bars are introduced into the rolling mill, the temperature of the introduction into the rolling mill is 500-550°C, and the outlet temperature is 350-420°C. Heated during hot rolling.

[0088] 2) After the aluminum alloy rod is formed into a circle, put it into a sealed heat preservation furnace or a heat preservation cover, and the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com