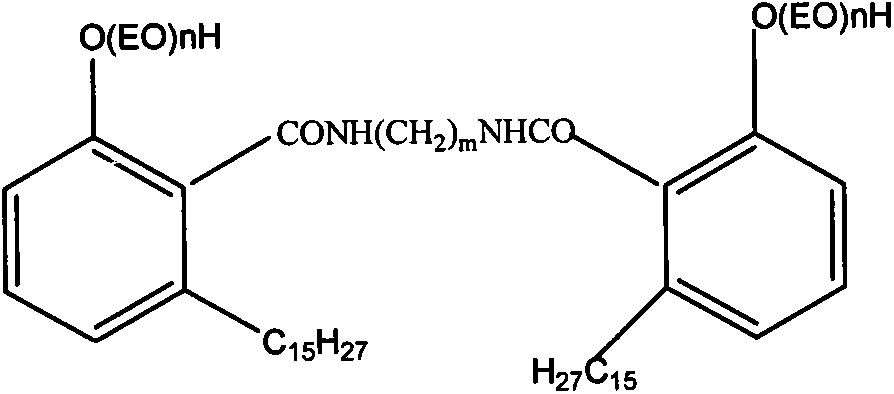

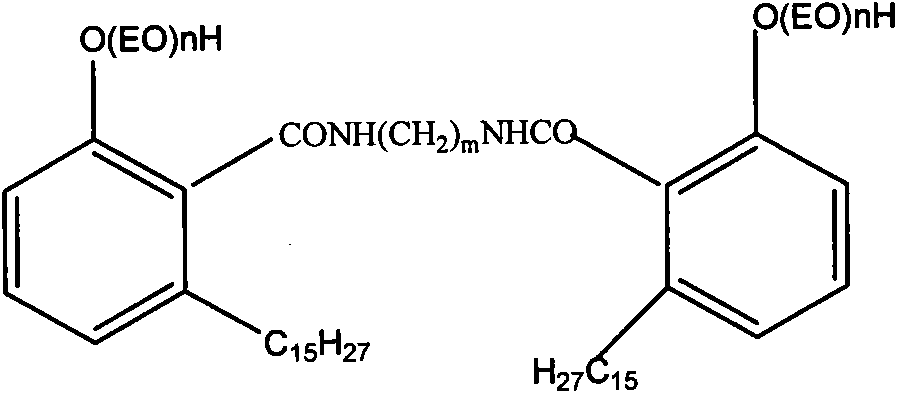

Cashew nut based amide surfactant and preparation method thereof

A technology of surfactant and amides, which is applied in the field of cashew-based amide surfactants and its preparation, can solve problems that need to be further developed, and achieve the effects of excellent emulsification and decontamination performance, high yield, and excellent salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

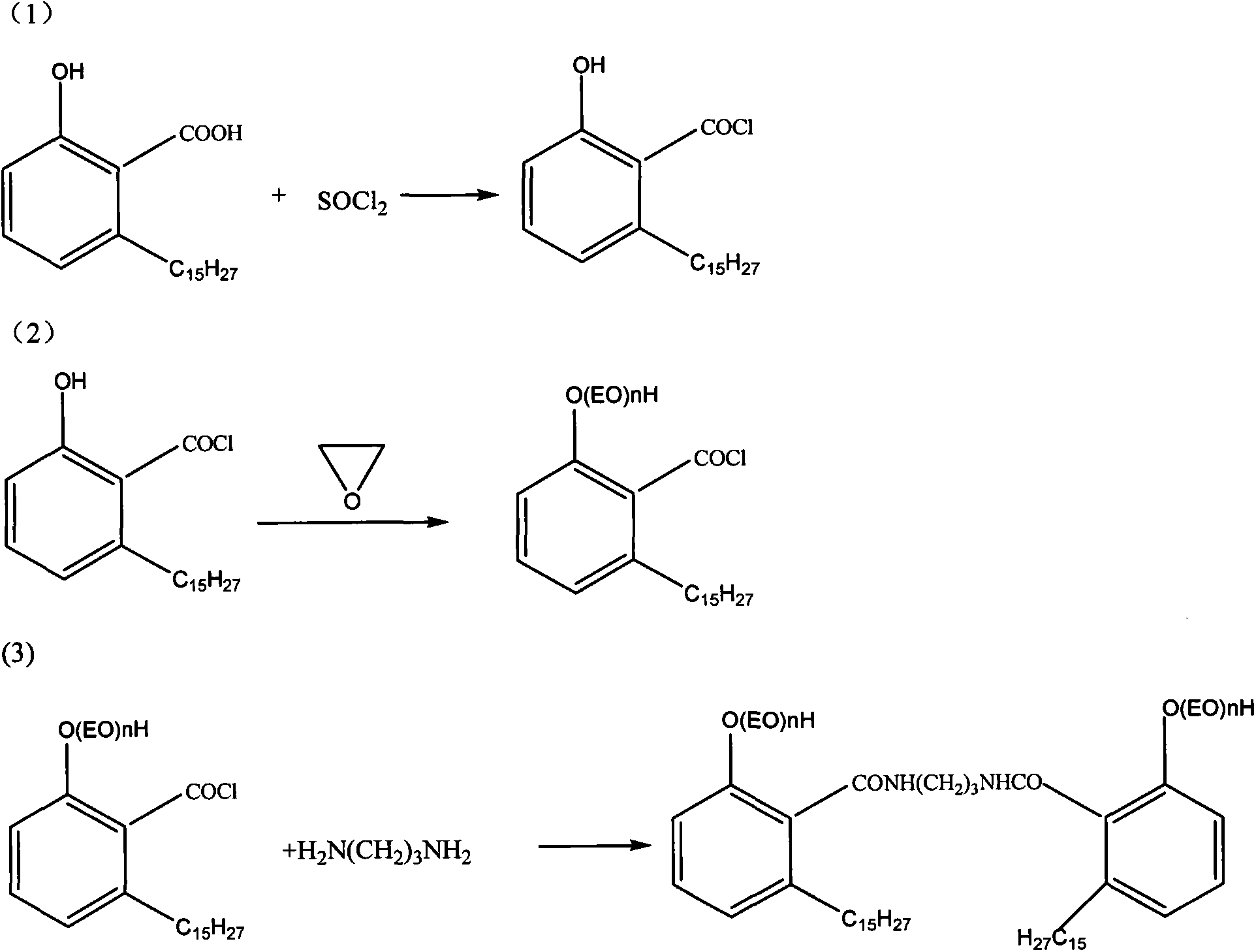

Method used

Image

Examples

Embodiment 1

[0019] 1) Add 42.26g of anacardic acid into a four-neck bottle, slowly heat up to 60°C (2, add 21.54g of thionyl chloride dropwise while stirring, react for 4 hours after the addition, and distill the excess thionyl chloride Rear underpressure distillation obtains 36.01g (2-hydroxyl-5-pentadecyl) benzoyl chloride. 2) 36.01g (2-hydroxyl-5-pentadecyl) benzoyl chloride and 8g alkali are added to the reactor In, after replacing 3 times with vacuum nitrogen, the temperature was raised to 140° C. and 40.10 g of ethylene oxide was added to fully stir, and the polymerization reaction was carried out for 4 hours to obtain 41.07 g (2-hydroxyl ether-5-pentadecyl) benzoyl chloride ( EO=3). 3) Add 41.07g (2-hydroxyether-5-pentadecyl)benzoyl chloride into the four-neck flask, add 6.84g 1,3-propanediamine dropwise under full stirring, and control the reaction temperature at 5°C for 0.5 Hour, purified to obtain 24.24g anacardiamide surfactant. The critical micelle concentration of this cash...

Embodiment 2

[0021] 1) Add 30.17g of anacardic acid into a four-neck bottle, slowly heat up to 50°C, add 11.04g of thionyl chloride dropwise while stirring, react for 3 hours after the addition, distill the excess thionyl chloride and reduce Pressure distillation gave 32.76 g of (2-hydroxy-4-pentadecyl)benzoyl chloride. 2) Add 32.76g (2-hydroxy-5-pentadecyl) benzoyl chloride and 4.13g base to the reaction kettle, replace it with vacuum nitrogen for 3 times, then raise the temperature to 135°C and add 41.26g ethylene oxide Thoroughly stirred and polymerized for 3 hours to obtain 51.20 g of (2-hydroxyether-5-pentadecyl)benzoyl chloride (EO=5). 3) Add 51.20g (2-hydroxyether-5-pentadecyl)benzoyl chloride into the four-neck flask, add 5.74g ethylenediamine dropwise under full stirring, control the reaction temperature at 8°C for 1 hour, and purify 29.42 g of anacardyl amide surfactant was obtained. The critical micelle concentration of this cashew-based surfactant is 2.77×10 -4 mol / L, the su...

Embodiment 3

[0023] 1) Add 34.25g of anacardic acid into a four-neck bottle, slowly heat up to 45°C, add 10.97g of thionyl chloride dropwise while stirring, react for 5 hours after the addition, distill the excess thionyl chloride and reduce Pressure distillation gave 35.10 g of (2-hydroxy-4-pentadecyl)benzoyl chloride. 2) Add 35.10g (2-hydroxy-5-pentadecyl) benzoyl chloride and 4.26g base to the reaction kettle, replace it with vacuum nitrogen for 3 times, then raise the temperature to 145°C and add 43.98g ethylene oxide Thoroughly stirred and polymerized for 5 hours to obtain 59.46 g of (2-hydroxyether-5-pentadecyl)benzoyl chloride (EO=7). 3) Add 59.46g (2-hydroxyether-5-pentadecyl)benzoyl chloride into the four-neck flask, add 8.17g of 1,4-butanediamine dropwise under full stirring, and control the reaction temperature at 10°C for 1.5 Hour, purified to obtain 34.59g anacardiamide surfactant. The critical micelle concentration of this cashew-based surfactant is 3.56×10 -4 mol / L, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com