Low-cost, high-strength and high-plasticity metastable beta titanium alloy and preparation method thereof

A β-titanium alloy, high-strength technology, applied in the field of low-cost, high-strength, high-plasticity metastable β-titanium alloy and its preparation, can solve the problems of high-cost alloy elements, gaps, low alloy strength, etc., to achieve fine structure, reduce The effect of alloy cost and uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The low-cost, high-strength, high-plasticity metastable beta titanium alloy of this embodiment includes the following chemical elements in weight percentages: Fe: 5wt.%, Al: 6wt.%, V: 4wt.%, O: ≤0.2wt.% , C: ≤0.08wt.%, N: ≤0.05wt.%, the balance is titanium and unavoidable impurities.

[0040] The method for preparing the low-cost, high-strength, and high-plasticity metastable beta titanium alloy of this embodiment is as follows:

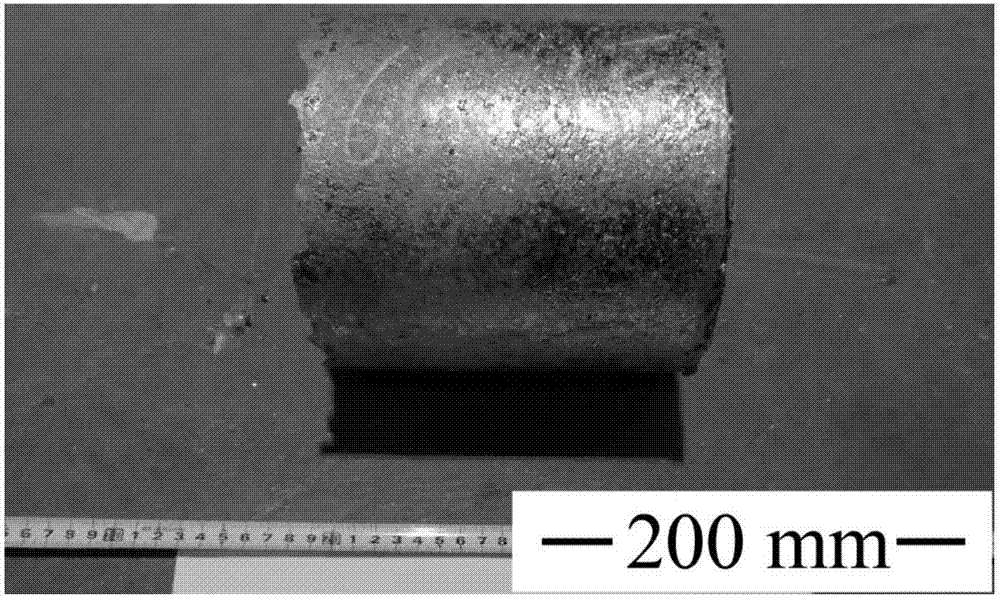

[0041] Weigh the sponge titanium, Al-V master alloy, pure Al, and pure Fe according to the above ratio. Among them, titanium is provided by sponge titanium, V is provided by Al-V master alloy, Al is provided by pure Al and Al-V master alloy, and Fe The mixed raw material is provided by pure Fe; after mixing according to the design composition, it is pressed into an electrode, and the electrode is smelted in a vacuum consumable arc melting furnace to obtain an alloy ingot with a diameter of 160mm (a primary ingot such as figure 1 As shown, the seco...

Embodiment 2

[0044] The low-cost, high-strength, high-plasticity metastable beta titanium alloy of this embodiment includes the following chemical elements in weight percentages: Fe: 5wt.%, Al: 6wt.%, V: 4wt.%, O: ≤0.2wt.% , C: ≤0.08wt.%, N: ≤0.05wt.%, the balance is titanium.

[0045] The method for preparing the low-cost, high-strength, and high-plasticity metastable beta titanium alloy of this embodiment is as follows:

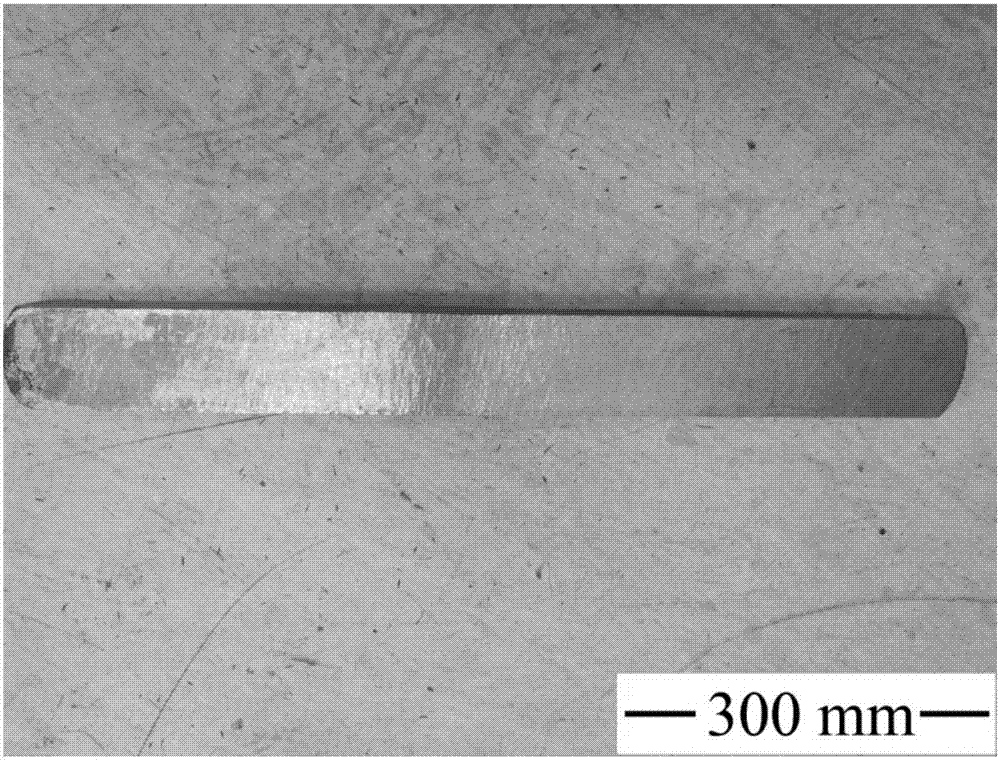

[0046] Weigh sponge titanium, Al-V master alloy, pure Al, and pure Fe according to the above-mentioned ratio. Titanium is provided by sponge titanium, V is provided by Al-V master alloy, Al is provided by pure Al and Al-V master alloy, and Fe The mixed raw material is provided by pure Fe; it is mixed according to the design composition and pressed into an electrode, and the electrode is smelted in a vacuum consumable arc melting furnace to obtain an alloy ingot with a diameter of 160mm, which is used in free forging equipment such as hydraulic press or forging hammer Open b...

Embodiment 3

[0049] The low-cost, high-strength, high-plasticity metastable beta titanium alloy of this embodiment includes the following chemical elements in weight percentages: Fe: 5wt.%, Al: 6wt.%, V: 4wt.%, O: ≤0.2wt.% , C: ≤0.08wt.%, N: ≤0.05wt.%, the balance is titanium.

[0050] The method for preparing the low-cost, high-strength, high-plasticity metastable beta titanium alloy of this embodiment is as follows:

[0051] Weigh sponge titanium, Al-V master alloy, pure Al, and pure Fe according to the above-mentioned ratio. Titanium is provided by sponge titanium, V is provided by Al-V master alloy, Al is provided by pure Al and Al-V master alloy, and Fe The mixed raw materials are provided by pure Fe; after mixing according to the design components, the electrodes are pressed into electrodes, and the electrodes are smelted in a vacuum consumable arc melting furnace to obtain alloy ingots with a diameter of 160mm, which are used in free forging equipment such as hydraulic presses or forging...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com