Horizontal branch multi-well-group butted well and construction method thereof

A technology of horizontal branching and construction methods, applied in the direction of boreholes/well components, drilling equipment and methods, drilling equipment, etc., to achieve the effects of reducing mining risks, reducing drilling costs, and reducing construction periods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

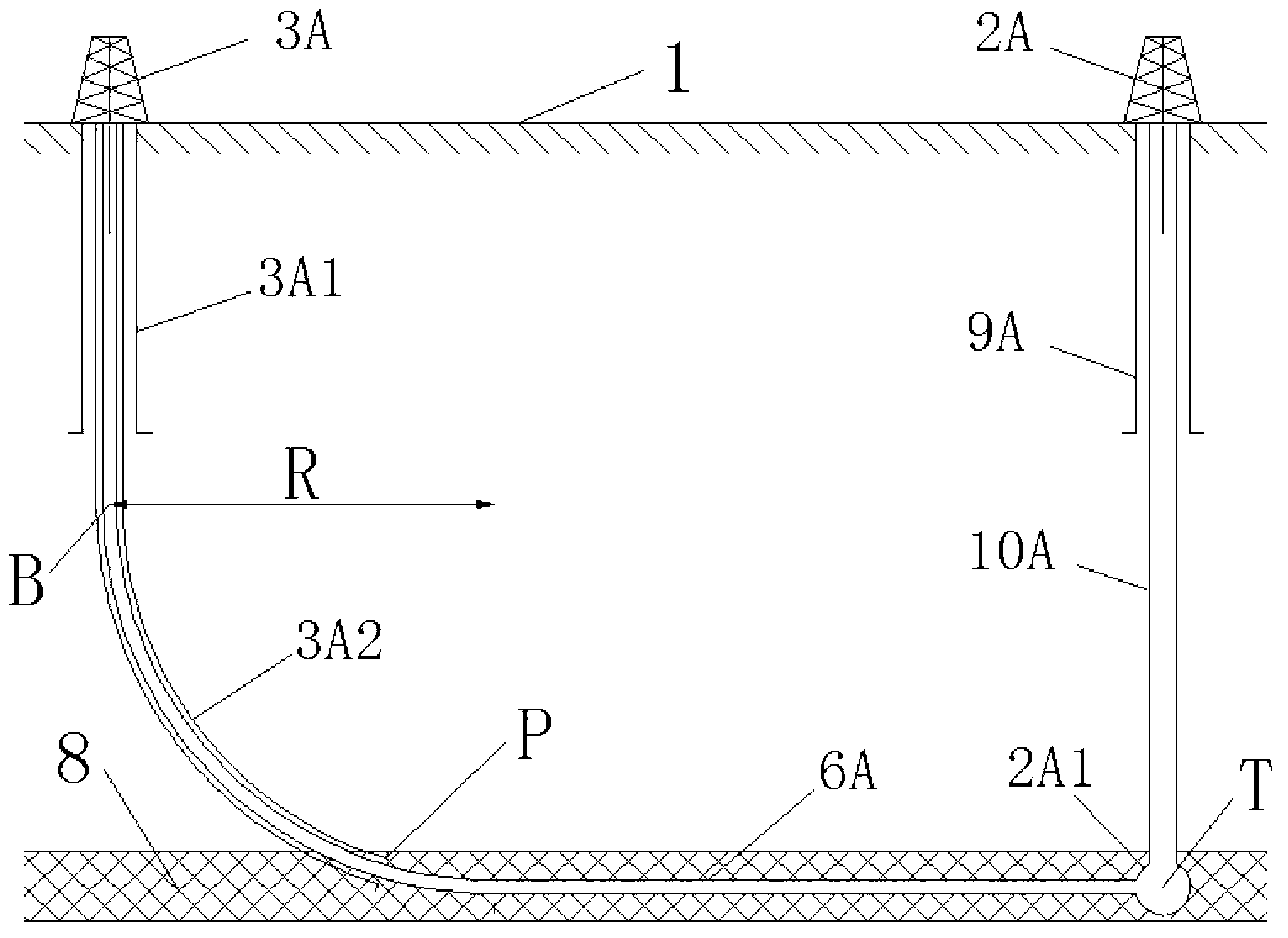

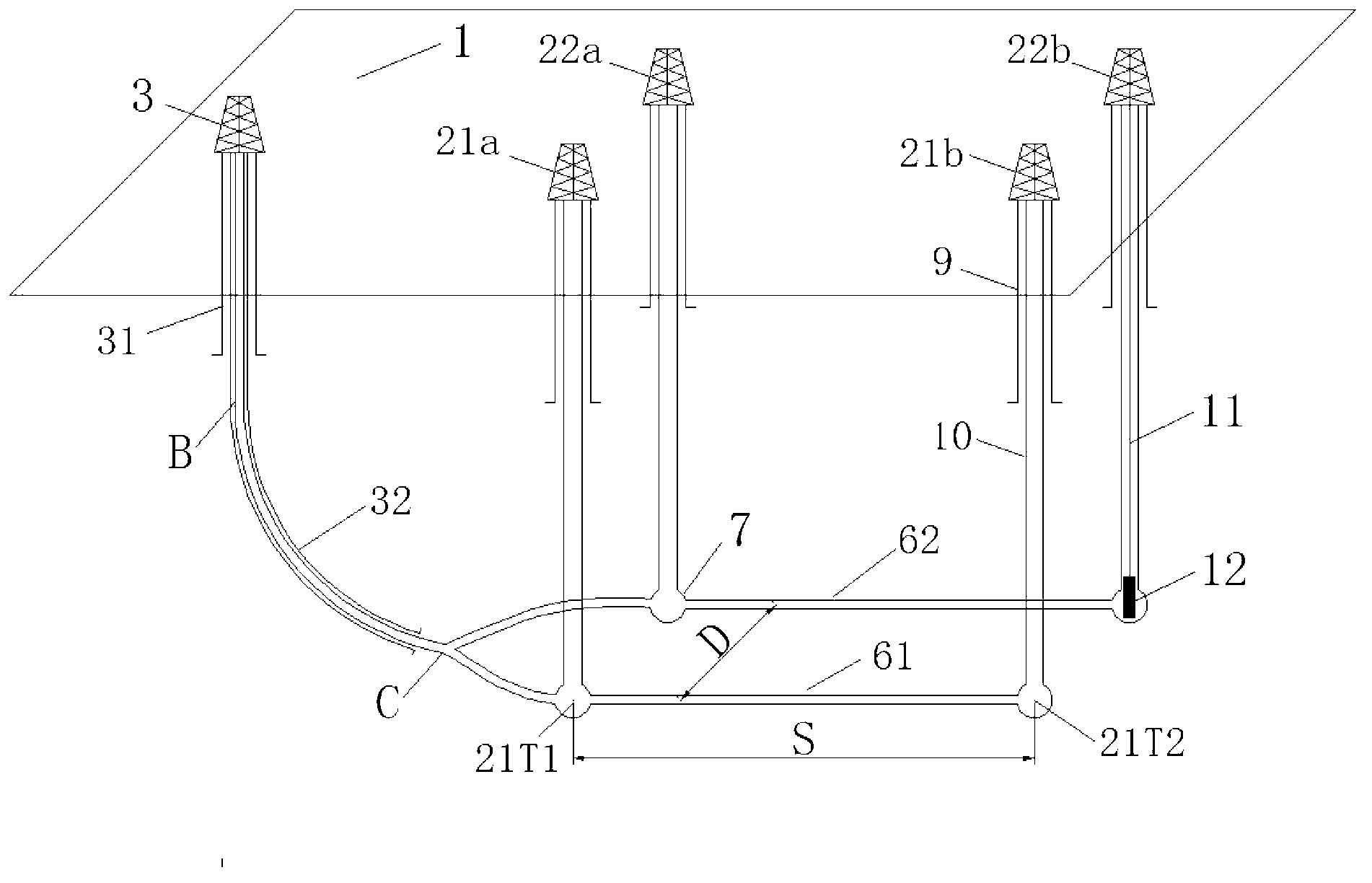

[0025] Embodiment 1: as figure 2 As shown, the horizontal branch multi-well group docking well in this embodiment adopts a distribution structure in which one horizontal well 3 corresponds to two vertical well groups, the first vertical well group includes two vertical wells 21a, 21b, and the second vertical well group includes Two vertical wells 22a, 22b; vertical wells 21a, 21b, 22a, 22b are connected to the horizontal well 3 at the target points at their respective bottoms (the target point 21T1 of the vertical well 21a and the target point 21T2 of the vertical well 21b are marked in the figure) , forming first and second horizontal mining passages 61, 62 corresponding to two vertical well groups one-to-one, wherein the target point at the bottom of the vertical well is located in the target ore seam 8 .

Embodiment 2

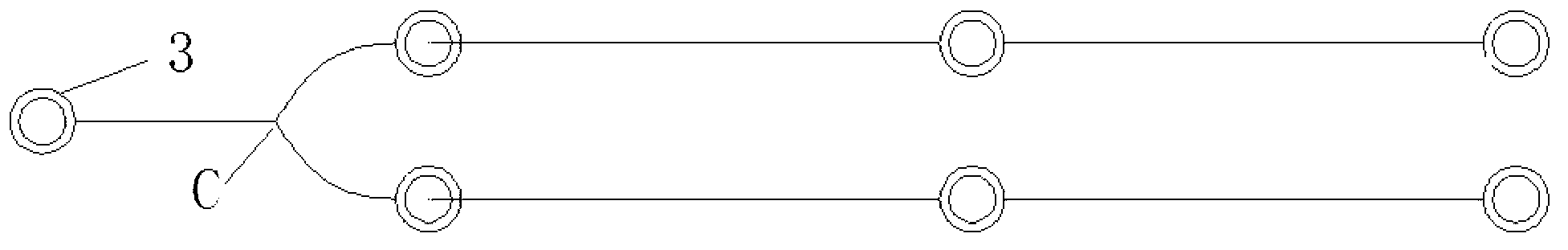

[0026] Embodiment 2: as Figure 3a As shown, the horizontal branch multi-well group docking well in this embodiment adopts a distribution structure in which one horizontal well 3 corresponds to two vertical well groups, and the two vertical well groups respectively include three vertical wells, forming two horizontal mining passages in total.

Embodiment 3

[0027] Embodiment 3: as Figure 3b As shown, the horizontal branch multi-well group docking well in this embodiment adopts a distribution structure in which one horizontal well 3 corresponds to three vertical well groups, and each vertical well group includes two vertical wells, forming three horizontal mining passages in total.

[0028] Now take the distribution structure of embodiment 1 as an example, specifically illustrate the construction method of the horizontal branch multi-well group butt joint well of the present invention:

[0029] Step 1: Drill four vertical wells 21a, 21b, 22a, 22b respectively to the target mineral layer 8, and perform mud logging and well logging to accurately determine the drilling depth of the target mineral layer 8, and control the well deviation of the drilled holes to make them as vertical as possible , run the vertical well surface casing 9 and the vertical well technical casing 10 respectively at corresponding depths, and cement the well w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com