Electrolyte for lithium-sulfur battery containing sulfide solubilizer

A lithium-sulfur battery and electrolyte technology, which is applied in the field of electrolyte, can solve the problems of low conductivity of sulfur and lithium sulfide, and reduced conductivity of the positive electrode.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

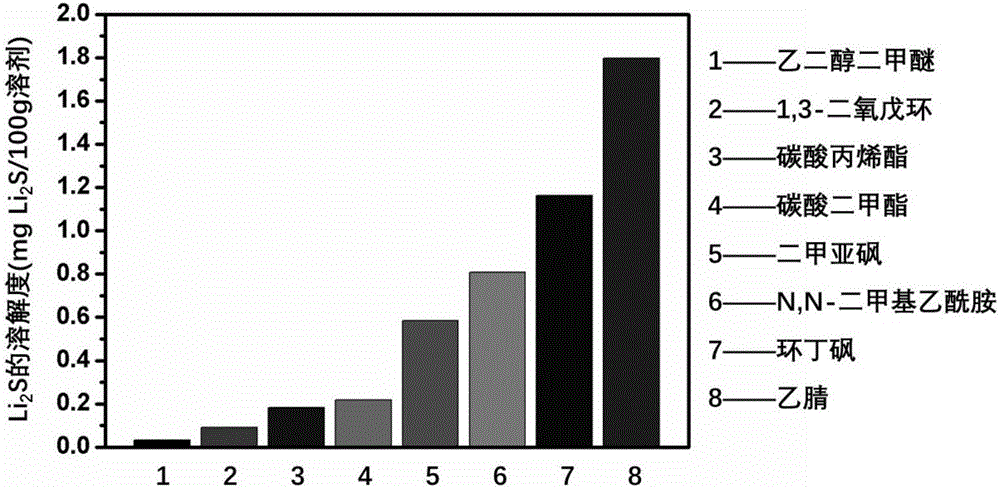

[0064]A kind of electrolytic solution that the present invention is used for lithium-sulfur battery mainly is made up of electrolytic salt, organic solvent, shuttle inhibitor and sulfide solubilizer, and this electrolytic salt is two (trifluoromethyl) sulfonylimide lithium (LiTFSI ), the concentration in the electrolyte is 1M, the organic solvent is a mixture of 1,3-dioxolane and ethylene glycol dimethyl ether in a volume ratio of 1:1, and the shuttle inhibitor is 0.2M lithium nitrate, sulfide The solubilizer is 4.3% of propylene carbonate, 2.6% of dimethyl sulfoxide, and 0.5% of acetonitrile.

[0065] The preparation method of the above-mentioned electrolyte solution of this embodiment includes the following steps: under the protection of an inert gas, prepare 1,3-dioxolane and ethylene glycol dimethyl ether solvent with a volume ratio of 1:1, and mix 1M bis( Lithium trifluoromethyl)sulfonylimide was dissolved in the mixed solvent, and the mixture was sonicated for 0.5 hours....

Embodiment 2

[0071] A kind of electrolytic solution that the present invention is used for lithium-sulfur battery mainly is made up of electrolytic salt, organic solvent, shuttle inhibitor and sulfide solubilizer, and this electrolytic salt is two (trifluoromethyl) sulfonylimide lithium (LiTFSI ), the concentration in the electrolyte is 1M, the organic solvent is a mixture of 1,3-dioxolane and ethylene glycol dimethyl ether in a volume ratio of 1:1, and the shuttle inhibitor is 0.2M lithium nitrate, sulfide The solubilizer is 2.7% of propylene carbonate, 3.6% of sulfolane, and 0.2% of acetonitrile.

[0072] Except that the electrolyte in this example is used instead of the electrolyte in Example 1, the composition, structure, preparation method and rate performance testing method of the lithium-sulfur battery in this example are exactly the same as those in Example 1.

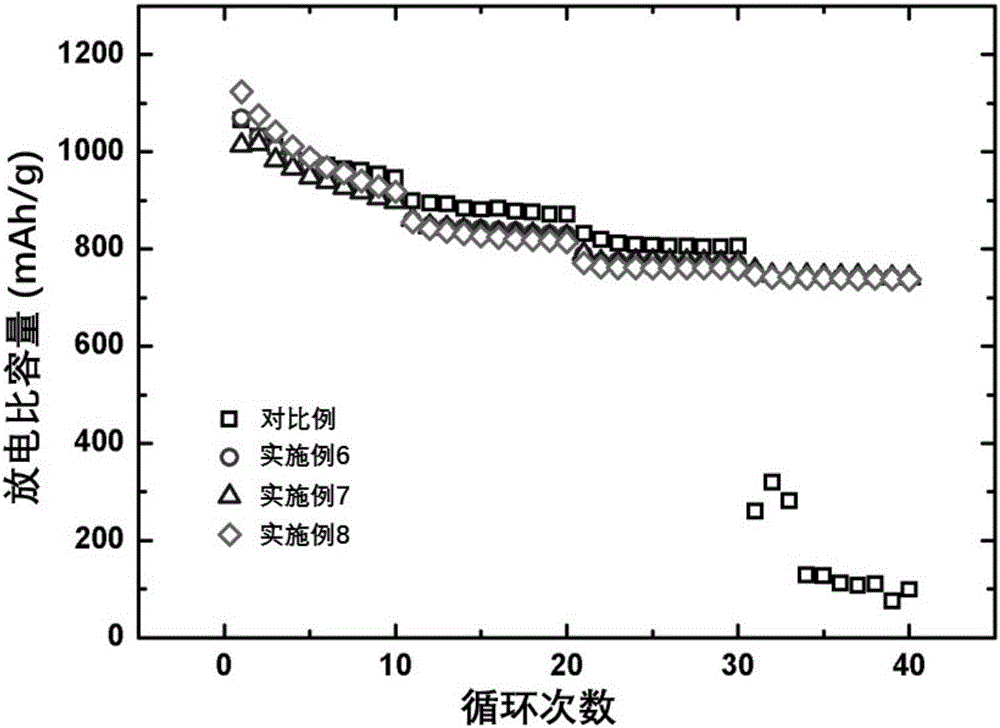

[0073] at 0.2 mA cm -2 Under the current density, the first discharge specific capacity is 1027mAh / g. After 40 cycles, ...

Embodiment 3

[0075] A kind of electrolytic solution that the present invention is used for lithium-sulfur battery mainly is made up of electrolytic salt, organic solvent, shuttle inhibitor and sulfide solubilizer, and this electrolytic salt is two (trifluoromethyl) sulfonylimide lithium (LiTFSI ), the concentration in the electrolyte is 1M, the organic solvent is a mixture of 1,3-dioxolane and ethylene glycol dimethyl ether in a volume ratio of 1:1, and the shuttle inhibitor is 0.2M lithium nitrate, sulfide The solubilizer is 2.7% of dimethyl carbonate, 1.8% of dimethyl sulfoxide, and 0.3% of acetonitrile.

[0076] Except that the electrolyte in this example is used instead of the electrolyte in Example 1, the composition, structure, preparation method and rate performance testing method of the lithium-sulfur battery in this example are exactly the same as those in Example 1.

[0077] at 0.2 mA cm -2 Under the current density, the first discharge specific capacity is 1110mAh / g. After 40 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com