Color mixer and reversing valve device thereof

A reversing valve and valve body technology, which is applied to valve devices, cocks including cut-off devices, mixers, etc., can solve the problem that the accuracy of a small amount of color paste cannot be guaranteed, the efficiency of a large amount of color paste is affected, and a small amount of color can not be achieved. The problem of paste injection, etc., can reduce the phenomenon of color paste drying, the structure is simple, and the effect of preventing color paste drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

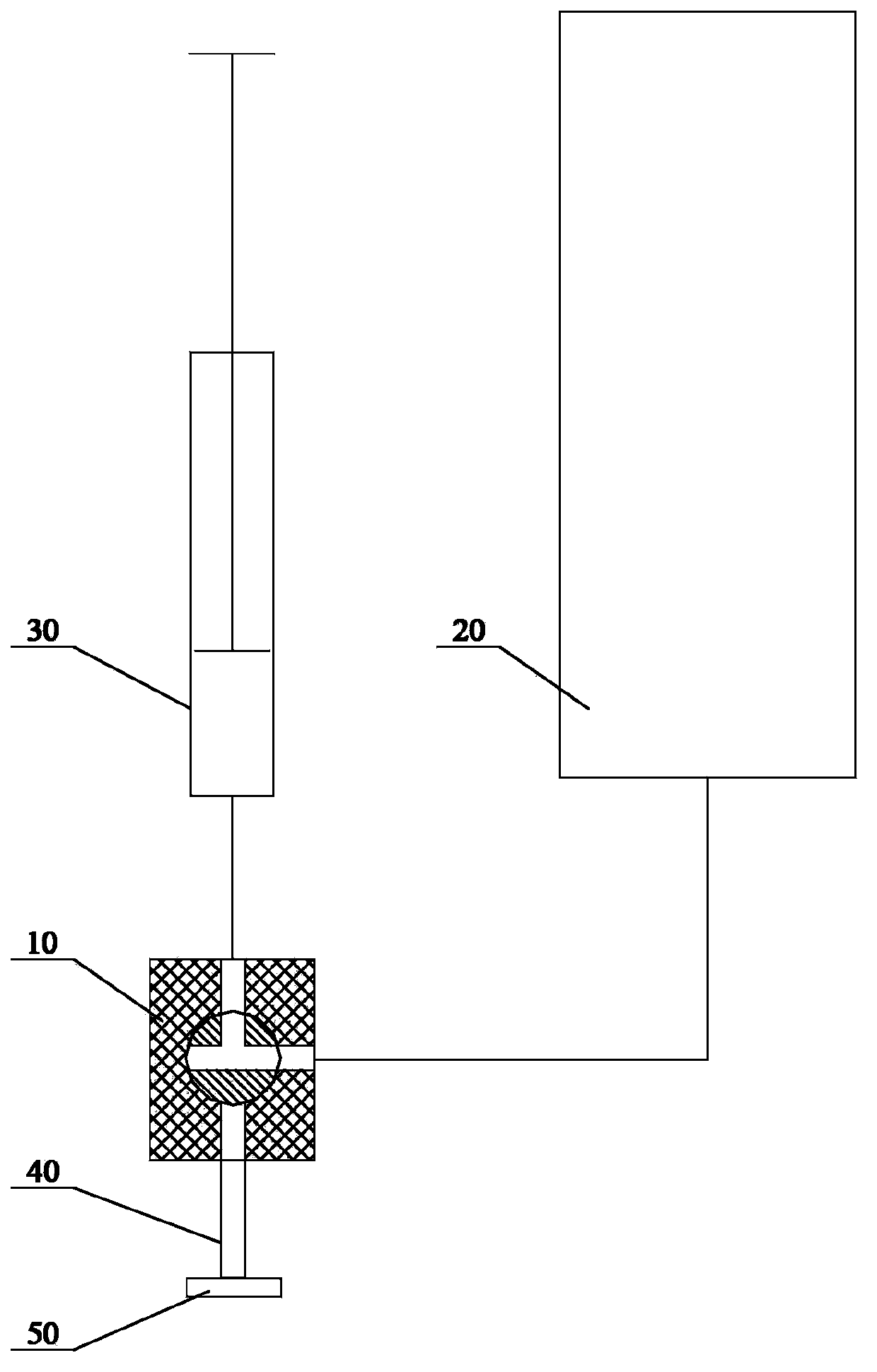

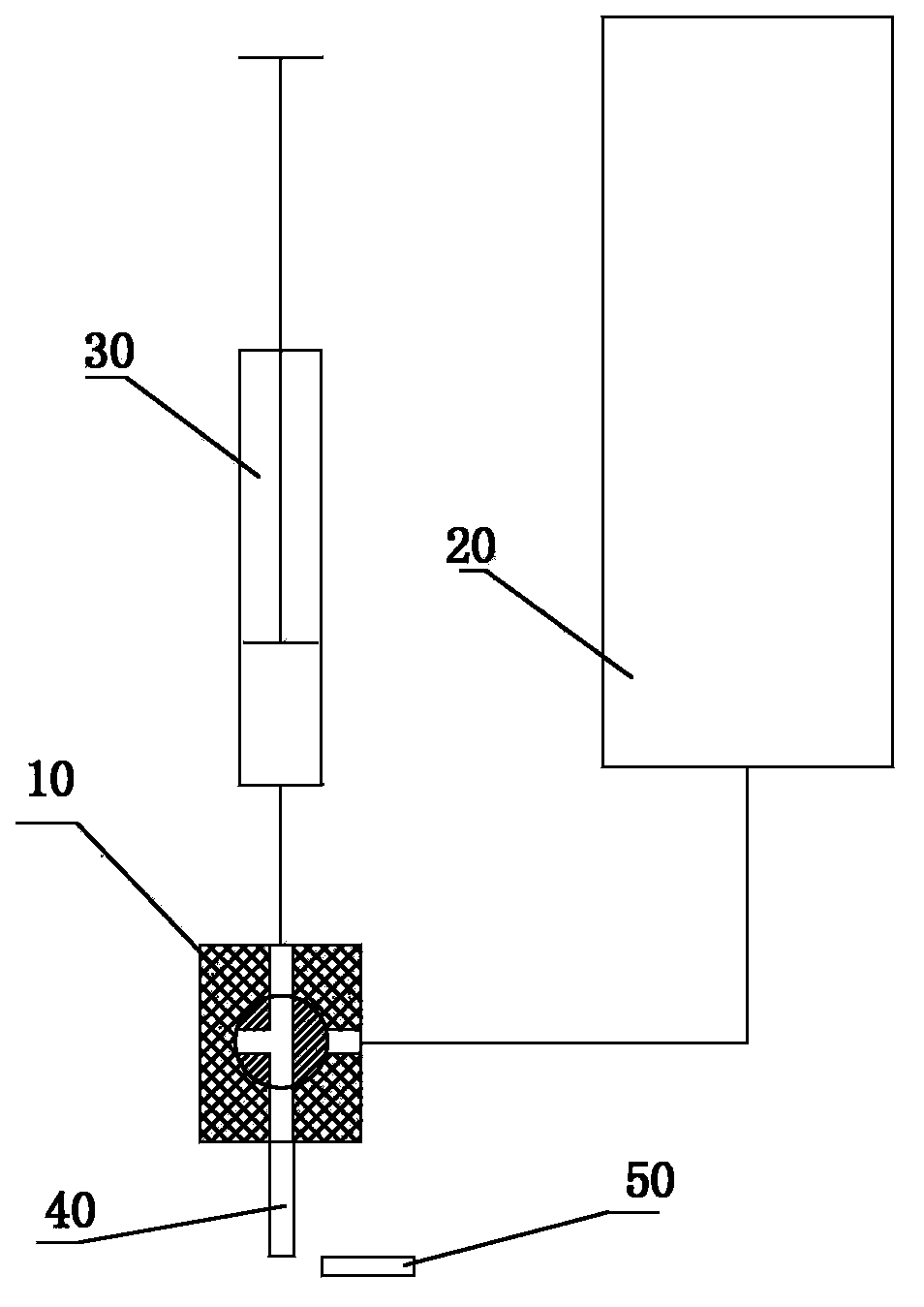

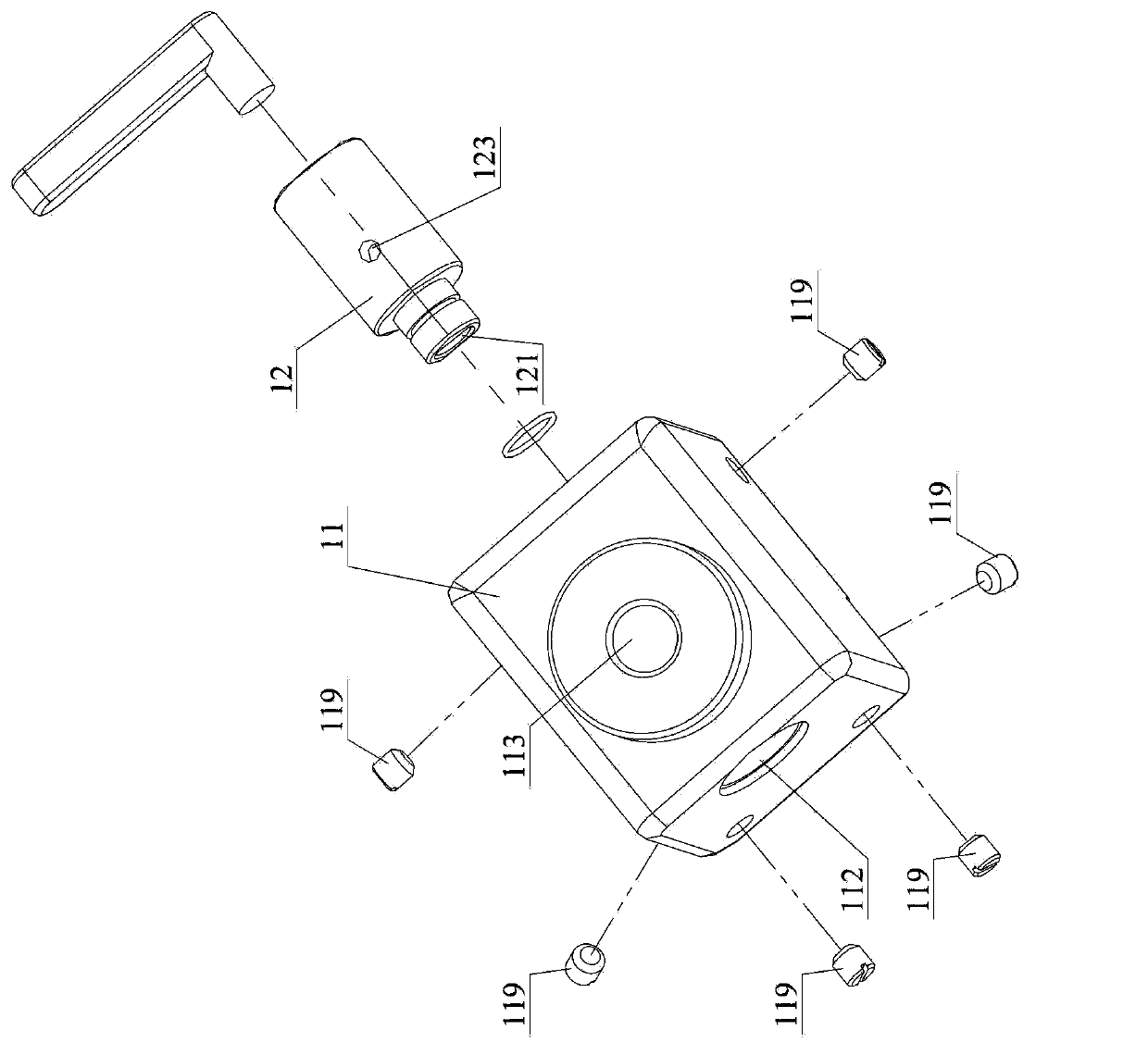

[0073] See image 3 , Figure 4 with Figure 5 ,in, image 3 It is an exploded schematic diagram of assembly of the reversing valve device described in the first embodiment, Figure 4 It is a top view of the reversing valve device described in the first embodiment, Figure 5 It is the front view of the reversing valve device described in the first embodiment.

[0074] In this embodiment, the main functional parts constituting the reversing valve device include a valve body 11 and a valve core 12, wherein the valve body 11 has an internal valve cavity 111 for accommodating the valve core 12, and the valve core 12 is pivotally connected to the internal valve cavity , so that it can be rotated to switch to different working positions and establish different conduction relationships. The valve body 11 is also provided with a first opening 112 and a second opening 113 communicating with the internal valve cavity 31. The first opening 112 is used to communicate with the color p...

Embodiment 2

[0085] See Figure 12 , Figure 13 , Figure 14 with Figure 15 ,in, Figure 12 It is an axonometric schematic diagram of the reversing valve device described in the second embodiment, Figure 13 for Figure 12 An exploded schematic diagram of the assembly of the reversing valve assembly shown in , Figure 14 for Figure 12 A-direction view, Figure 15 for Figure 12 B direction view.

[0086] The basic working principle of this embodiment is completely the same as that of the first embodiment. The valve body 21 has an inner valve cavity 211 for accommodating the valve core 22, and the valve core 22 is pivotally connected in the inner valve cavity to establish different conduction relationships. The valve body 21 is also provided with a first opening 212, a second opening 213 and a sixth opening 219 communicating with the internal valve chamber 211, wherein the first opening 212 and the sixth opening 219 are respectively used for connecting with the color paste conta...

Embodiment 3

[0093] See Figure 21 , which is a schematic structural diagram of the reversing valve device described in this embodiment.

[0094] Except for the setting position of the second opening, the structure and connection relationship of the reversing valve device in this embodiment are completely the same as those in the second embodiment, so please refer to the second embodiment for specific structural details.

[0095] In order to clearly show the difference and connection between the present embodiment and the second embodiment, the corresponding components and structures described are marked with the same symbols in the drawings of the present embodiment. As shown in the figure, in this solution, the second opening 213 used to communicate with the injection pump (shown by double-dashed lines) is opened on the lower surface of the valve body 21, and the corresponding slurry port of the injection pump communicated with the valve body 21 faces In this way, when there is gas in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com