Integration design method for hypersonic slender body air vehicle and three-dimensional inward rotation air inlet channel

A hypersonic, design method technology, applied in aircraft parts, ground installations, transportation and packaging, etc., to achieve the effect of broadening the range of working Mach numbers and high lift resistance characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

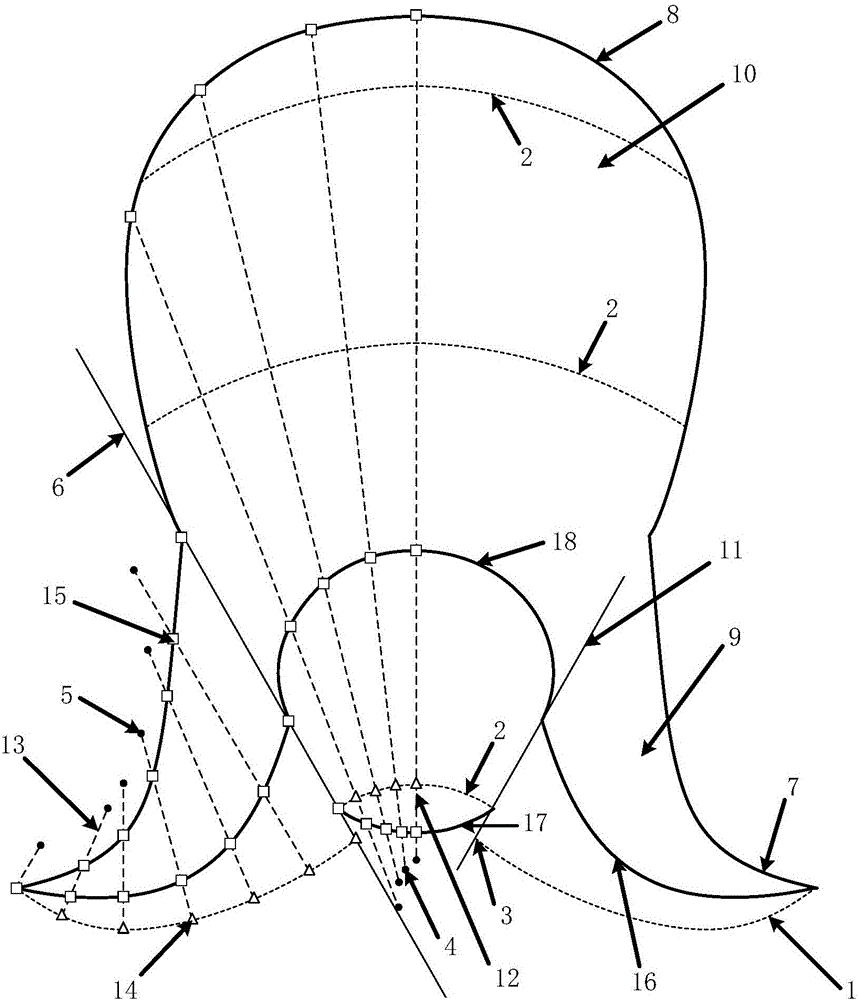

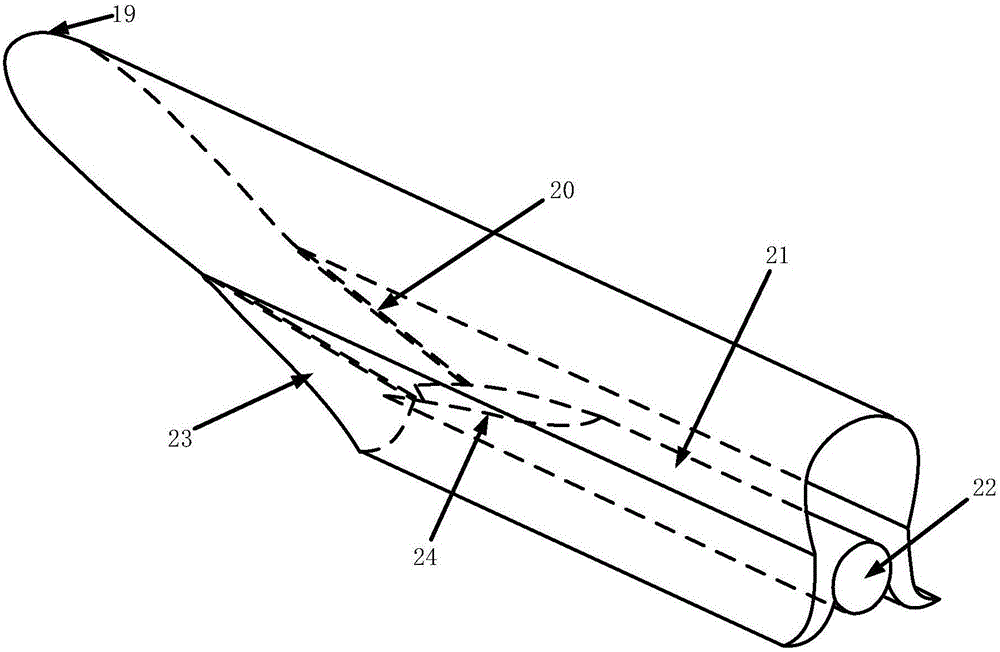

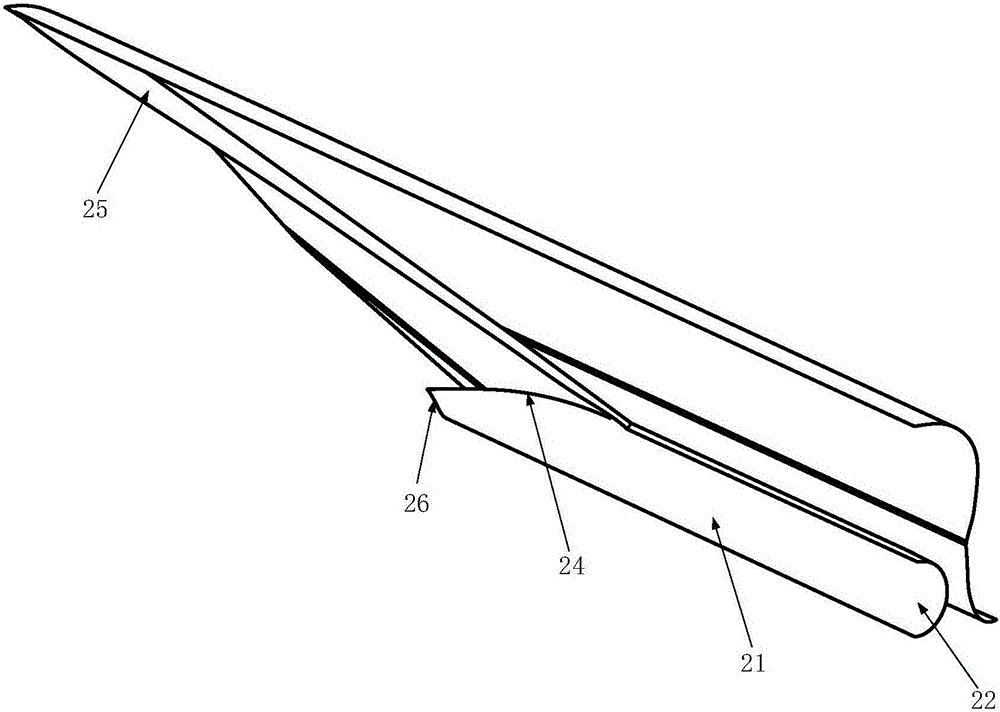

[0026] Such as Figure 1~5 As shown, the integration scheme of the hypersonic slender body aircraft and the three-dimensional inward turning inlet includes the slender waverider aircraft precursor 23 and the three-dimensional inturning inlet, wherein the aspect ratio of the integrated device is 26, and the three-dimensional inner turning inlet The air inlet consists of a three-dimensional inner turning inlet compression surface 25, a three-dimensional inner turning inlet lip 26, a three-dimensional inner turning inlet shoulder 24, a three-dimensional inner turning inlet isolation section 21 and a three-dimensional inner turning inlet Transverse overflow port 28 is formed. And the three-dimensional inward turning inlet can realize internal wave riding. The front body 23 of the slender waverider aircraft and the three-dimensional inward turning inlet are connected and transitioned by means of the binary wedge guide band 20, and the three-dimensional inner turning inlet profile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com