Internal waverider hypersonic inlet and design method for giving attention to internal and external flow performance

A design method and air intake technology, applied to the air intake of the turbine/propulsion device, combustion air/combustion-air treatment, engine components, etc., can solve the problems of high flow field quality, high outflow resistance, etc., and reach the working Mach number The effect of wide range, high internal flow quality and high airflow quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

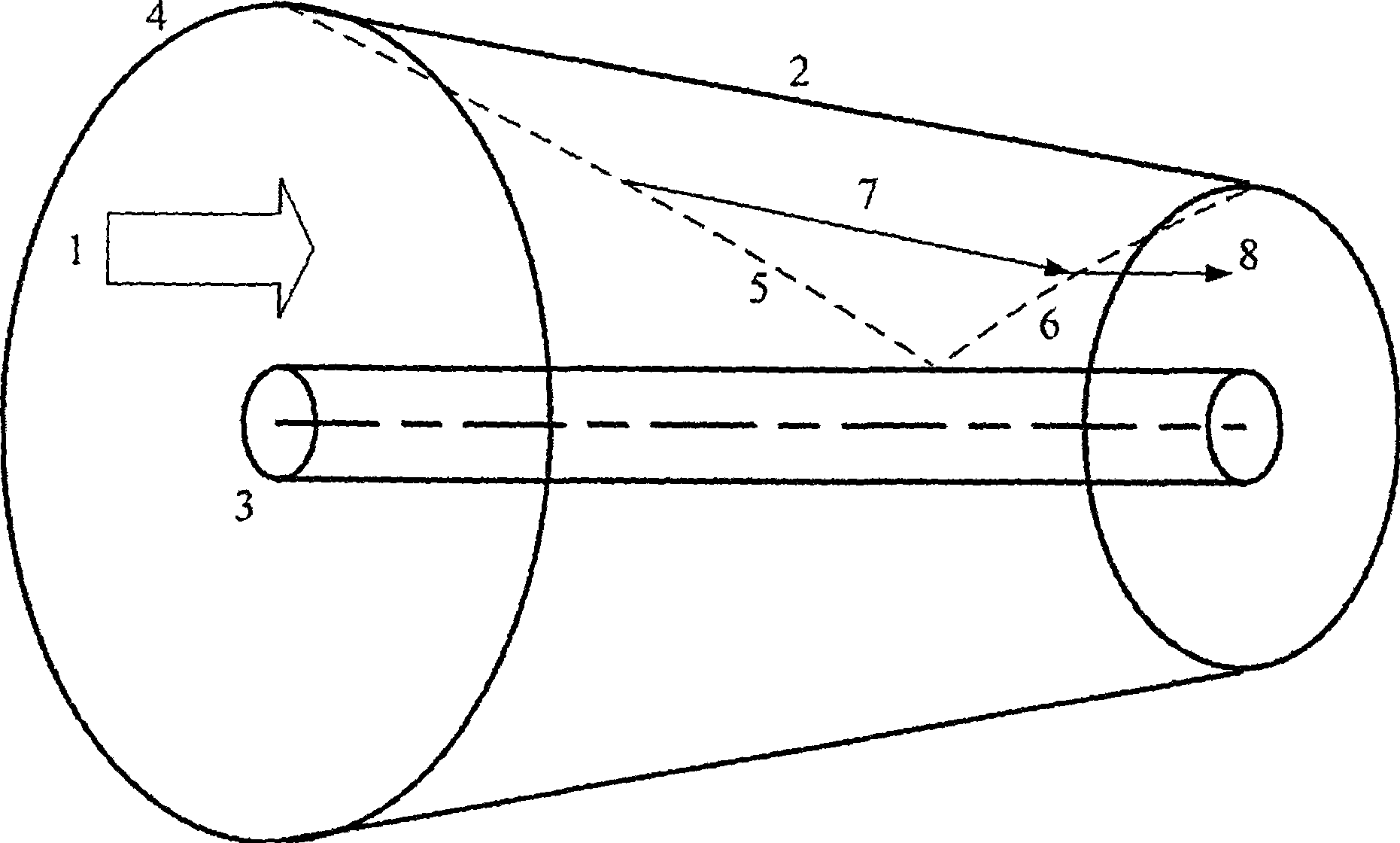

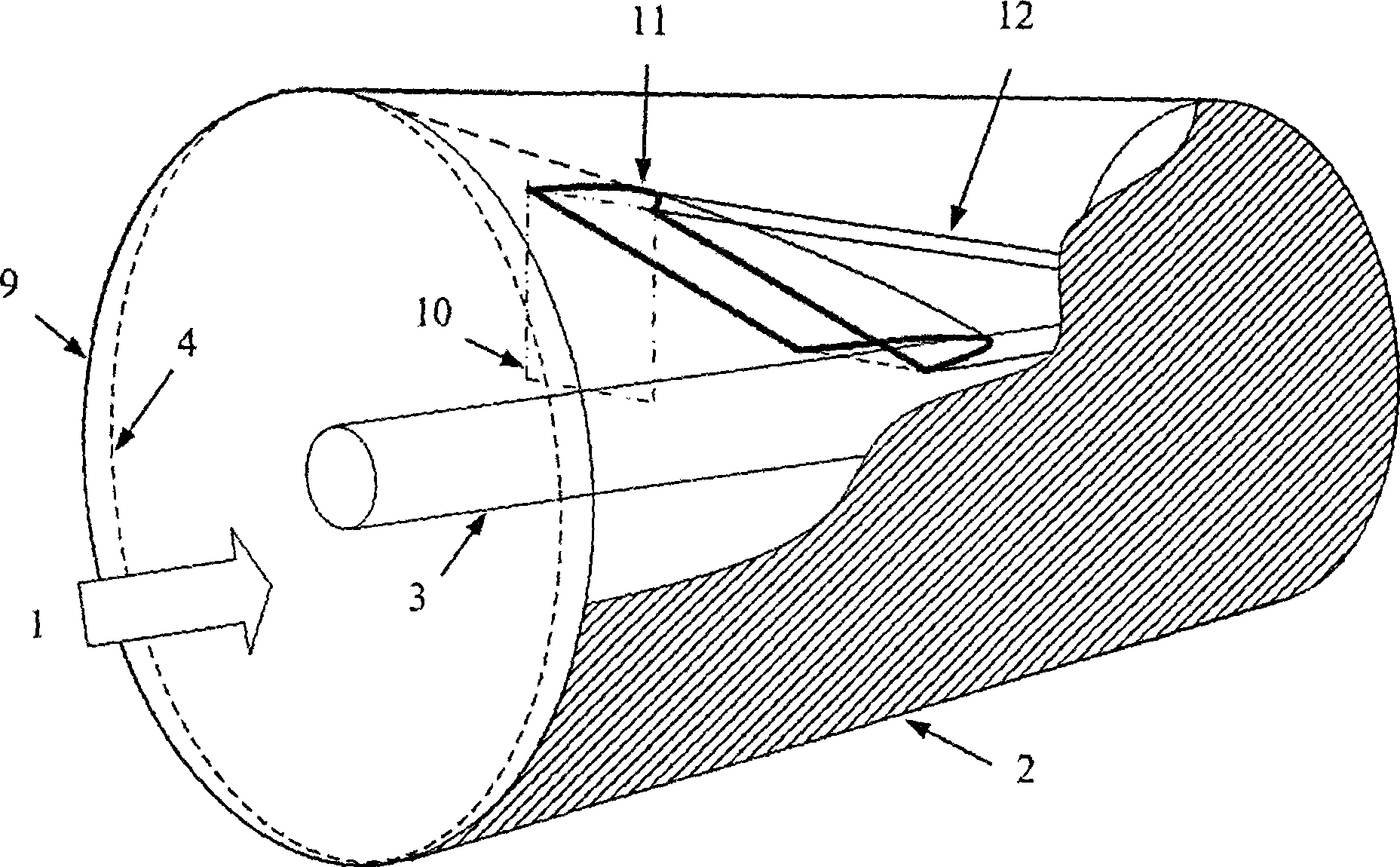

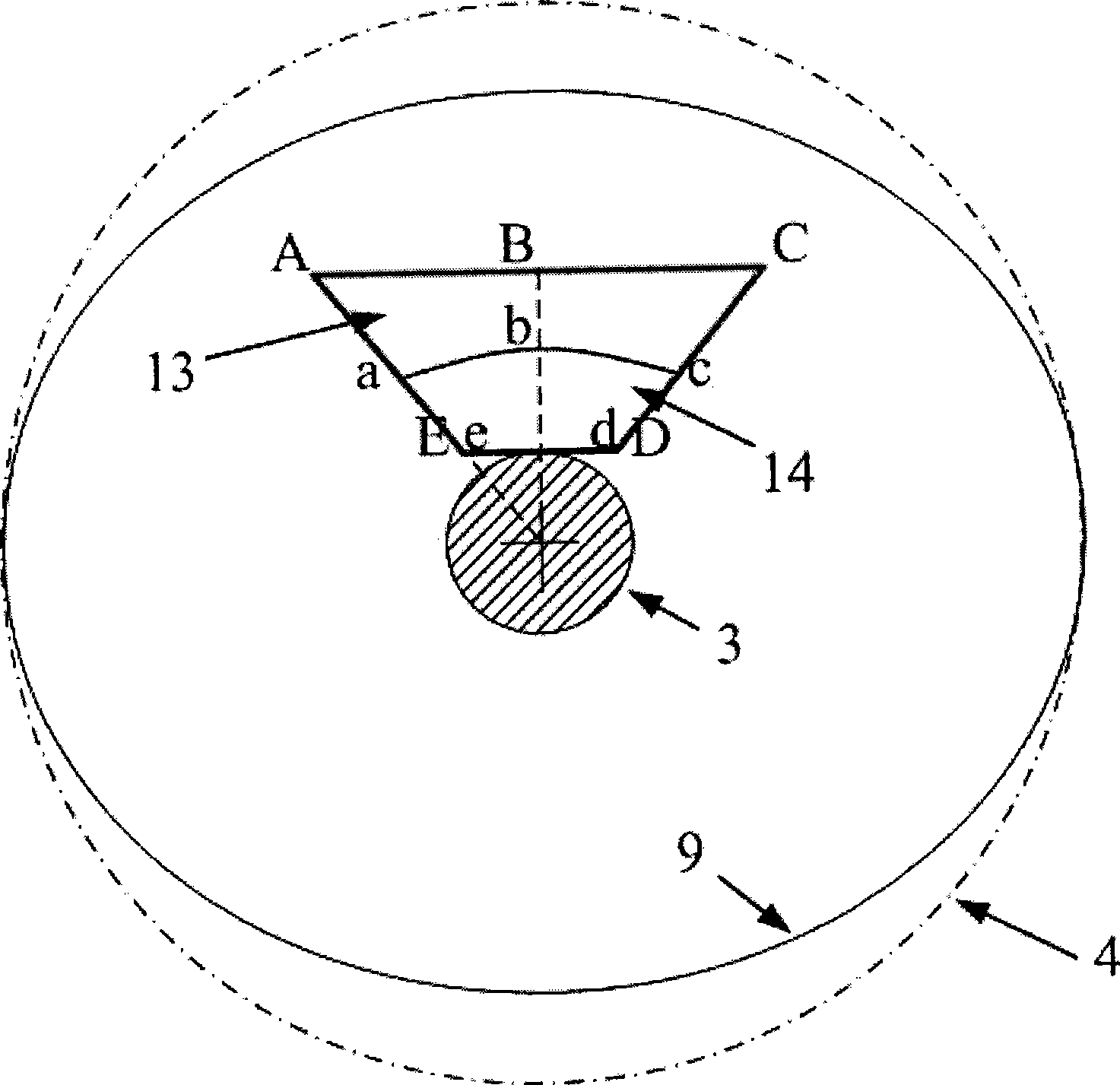

[0022] For the case where the design flight Mach number is 5, the following figure 2 A non-axisymmetric internal contraction basic flow field is shown, the profile line of the internal contraction wall is a cubic curve, and the initial internal contraction angle is 8 degrees; the inlet of the internal contraction pipe is elliptical, and its minor semi-axis is smaller than the major semi-axis 15%. The design requirements for the shape of the air inlet are: the projected shape of the inlet of the air inlet on the windward side is trapezoidal (see image 3 ), and the extension line of the two hypotenuses of the trapezoid on the windward side passes through the center of the cylinder central body. attached Figure 4 is the designed three-dimensional profile of the inner waverider hypersonic inlet.

[0023] In the design state of the incoming flow Mach number 5, the calculation results of the inlet show that the design scheme of this example has obtained the internal flow perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com