Display base board, preparation method thereof, and display apparatus

A display substrate and display unit technology, which is applied in semiconductor/solid-state device manufacturing, instruments, electrical digital data processing, etc., can solve the unfavorable problems of thinner display panels, thicker thickness, and low integration of substrates, so as to improve integration and The effect of added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

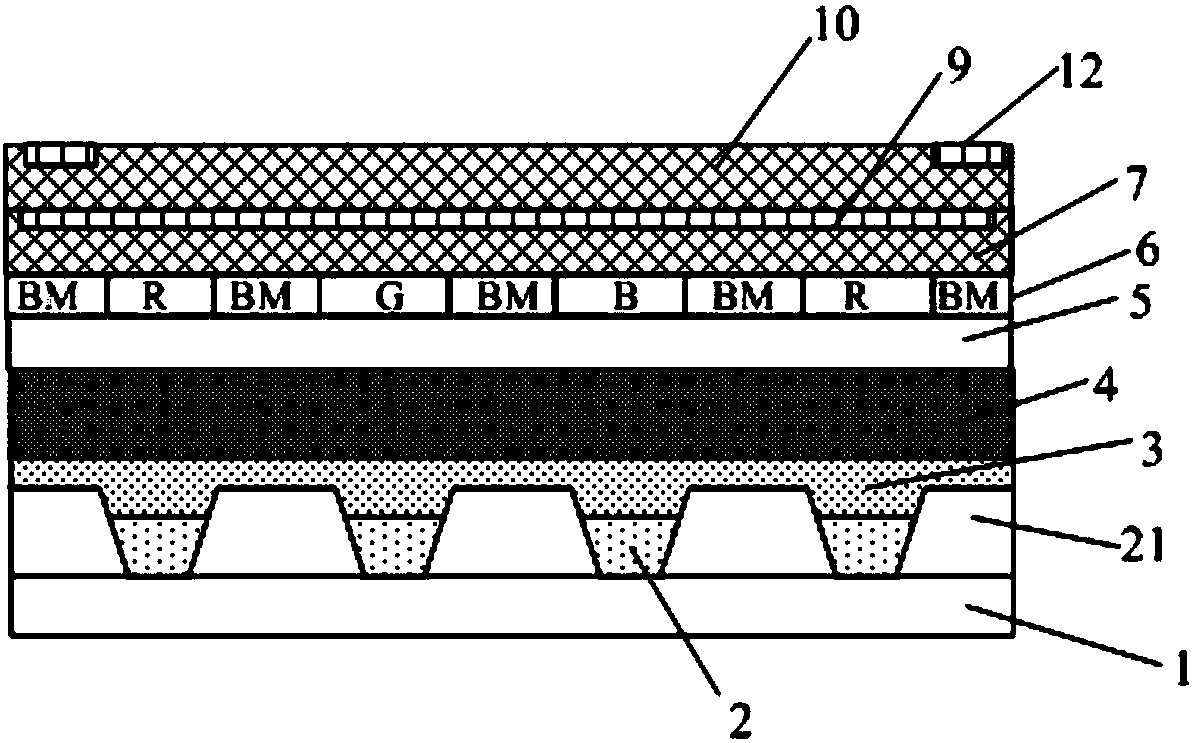

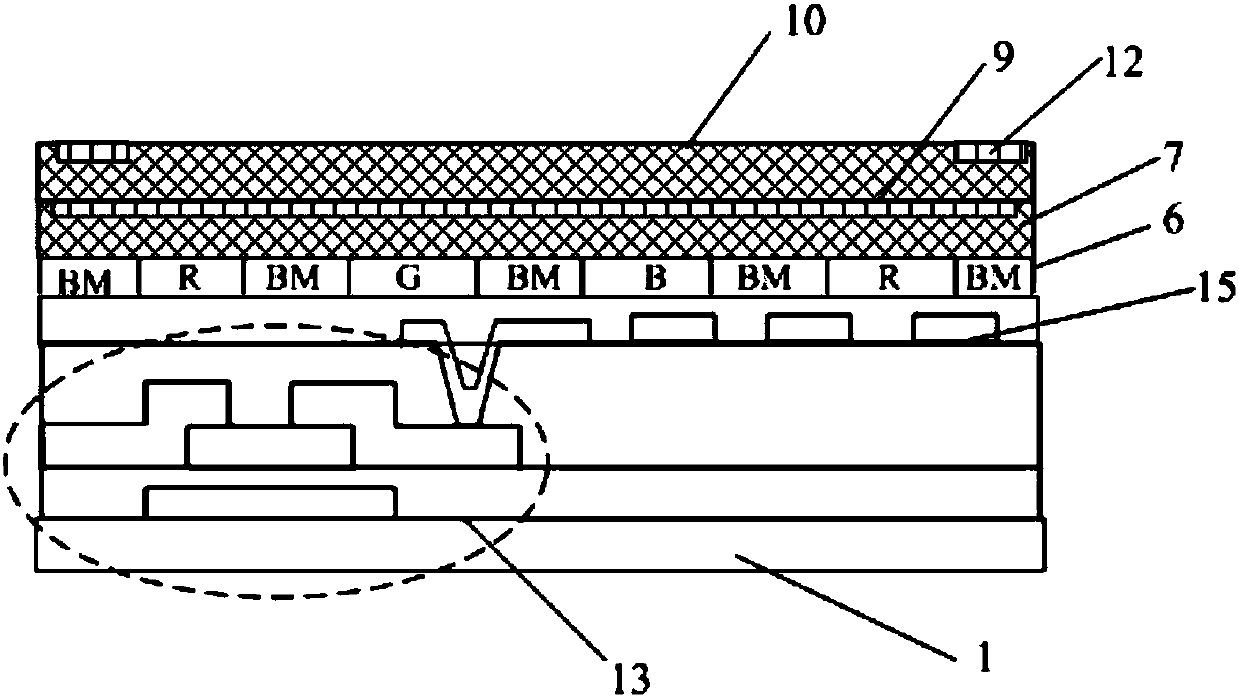

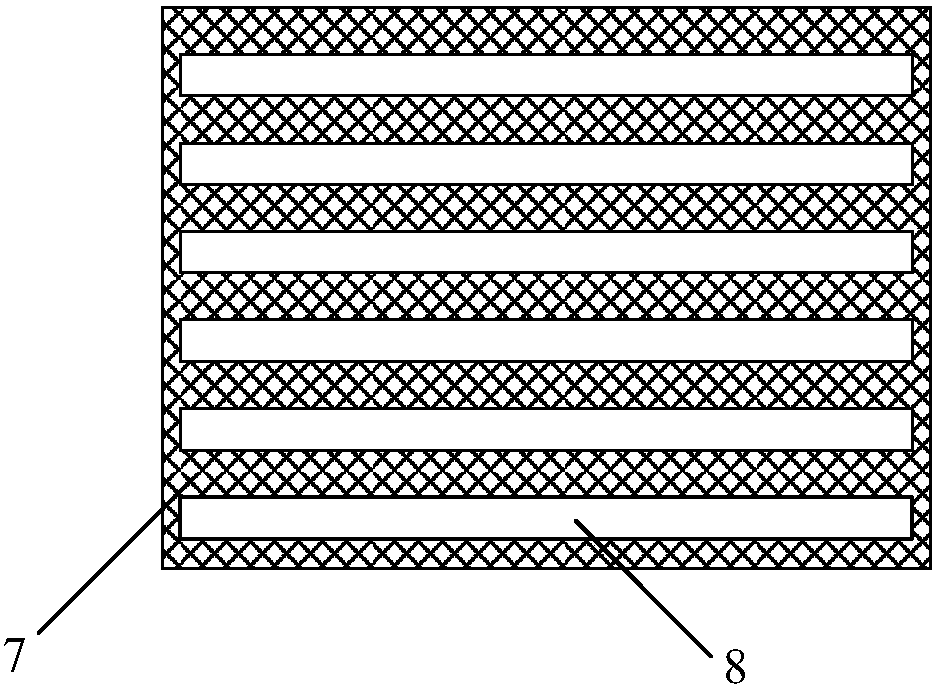

[0060] combine Figure 1-5 As shown, this embodiment provides a display substrate, including a substrate 1, a display unit disposed above the substrate 1, a color filter layer 6 disposed above the display unit, and a first flat layer sequentially disposed above the color filter layer 6 7 and the second flat layer 10; wherein, a plurality of first grooves 8 are arranged on the first flat layer 7; a plurality of second grooves 11 are arranged on the second flat layer 10; a plurality of first grooves Orthographic projections of 8 and multiple second grooves 11 on the substrate 1 are intersected; the first grooves 8 are filled with first wires 9; the second grooves 11 are filled with second wires 12 .

[0061]It can be understood that one of the first wire 9 and the second wire 12 can be used as a touch electrode, and the other can be used as a sensing electrode. That is to say, in the display substrate of this embodiment, the touch electrodes in the touch substrate are integrate...

Embodiment 2

[0076] combine figure 1 , 2 , 6-12 This embodiment provides a method for preparing a display substrate, and the display substrate is the display substrate in Embodiment 1. Described preparation method specifically comprises the following steps:

[0077] Step 1, forming a display unit on the substrate 1 .

[0078] Specifically, such as Figure 7 As shown, if the display substrate is an OLED substrate, Step 1 specifically includes: 1) Sputtering an anode conductive film on the substrate 1, and forming a pattern including the anode layer through a patterning process; 2) forming an anode layer on the substrate 1 1, forming a pattern including the pixel defining layer 21 through a patterning process; 3) on the substrate 1 formed with the pixel defining layer 21, using a vacuum evaporation process to form a light emitting layer in the opening of the pixel defining layer 2121; 4) in On the substrate 1 for forming the luminescent layer, a cathode layer is formed by using a vacuum ...

Embodiment 3

[0090]This embodiment provides a display device, which includes the display substrate described in Embodiment 1, so the display device of this embodiment has high integration and high added value, and can be applied to flexible displays.

[0091] The display device can be any product or component with a display function such as electronic paper, OLED panel, mobile phone, tablet computer, television, monitor, notebook computer, digital photo frame, navigator, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com