Screw device and cavity filter using the same

A cavity filter and screw technology, which is applied to waveguide devices, nuts, bolts, etc., can solve the problems of inconvenient use and increase the thickness of the filter, and achieve the effect of increasing the thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

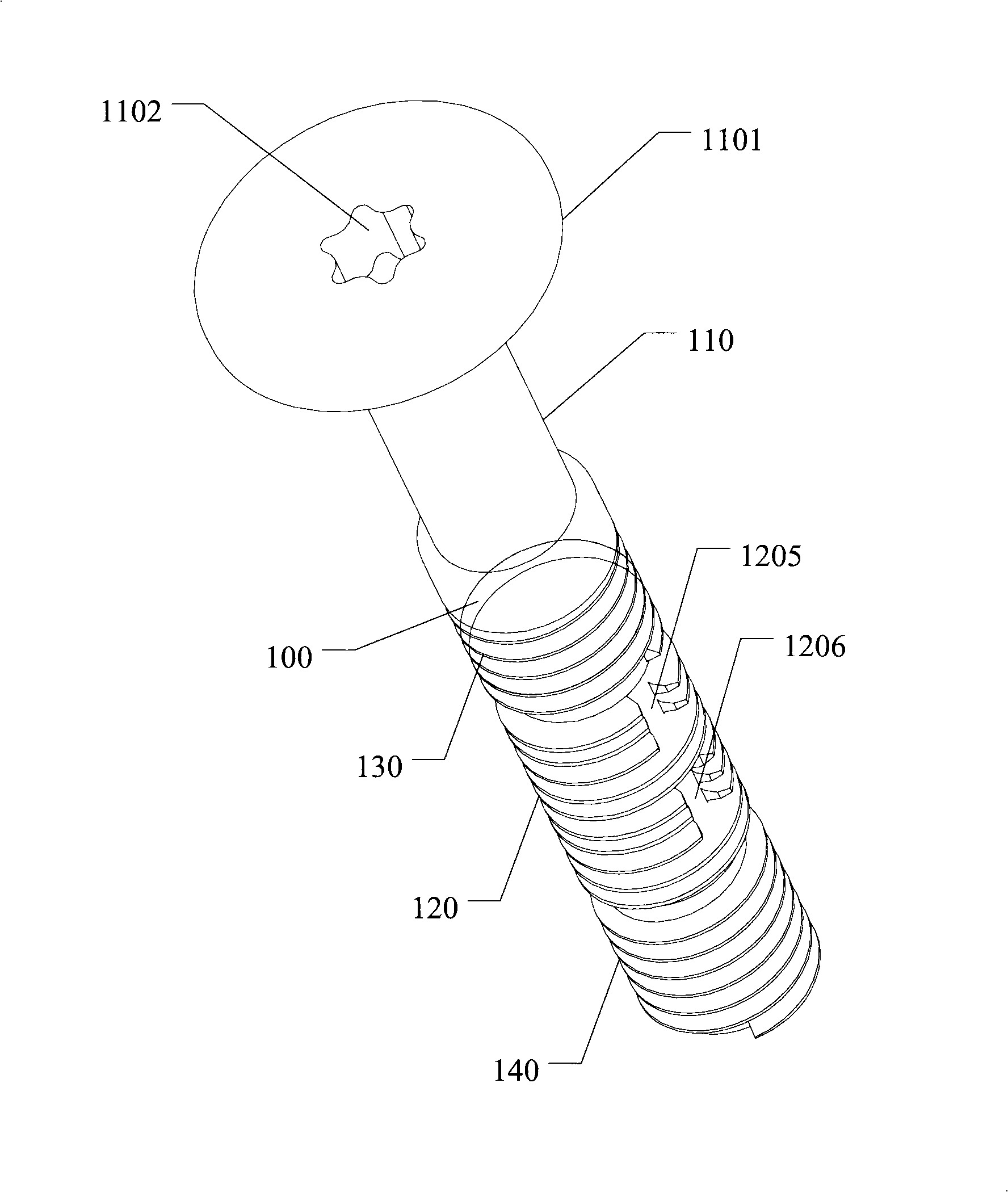

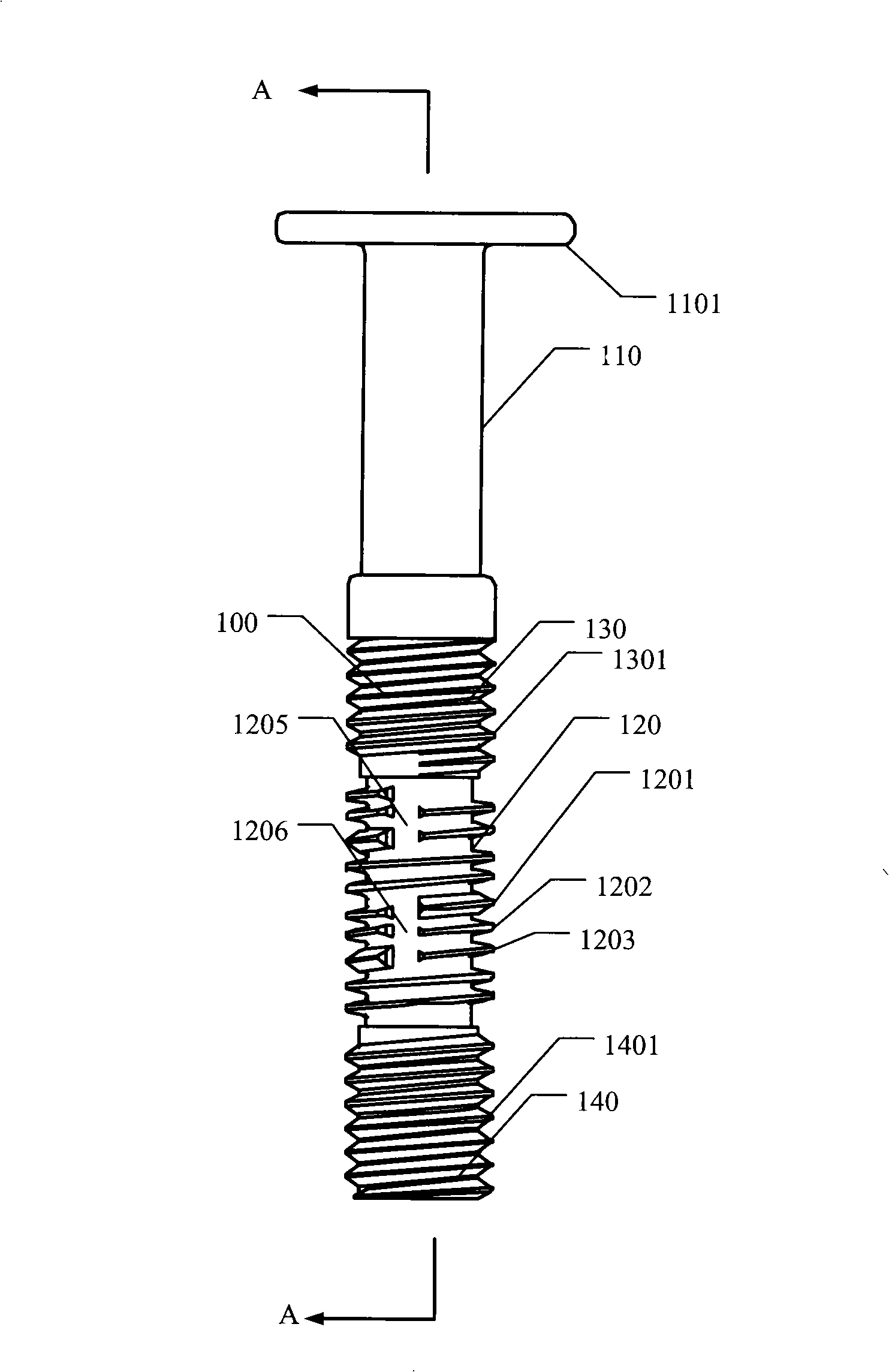

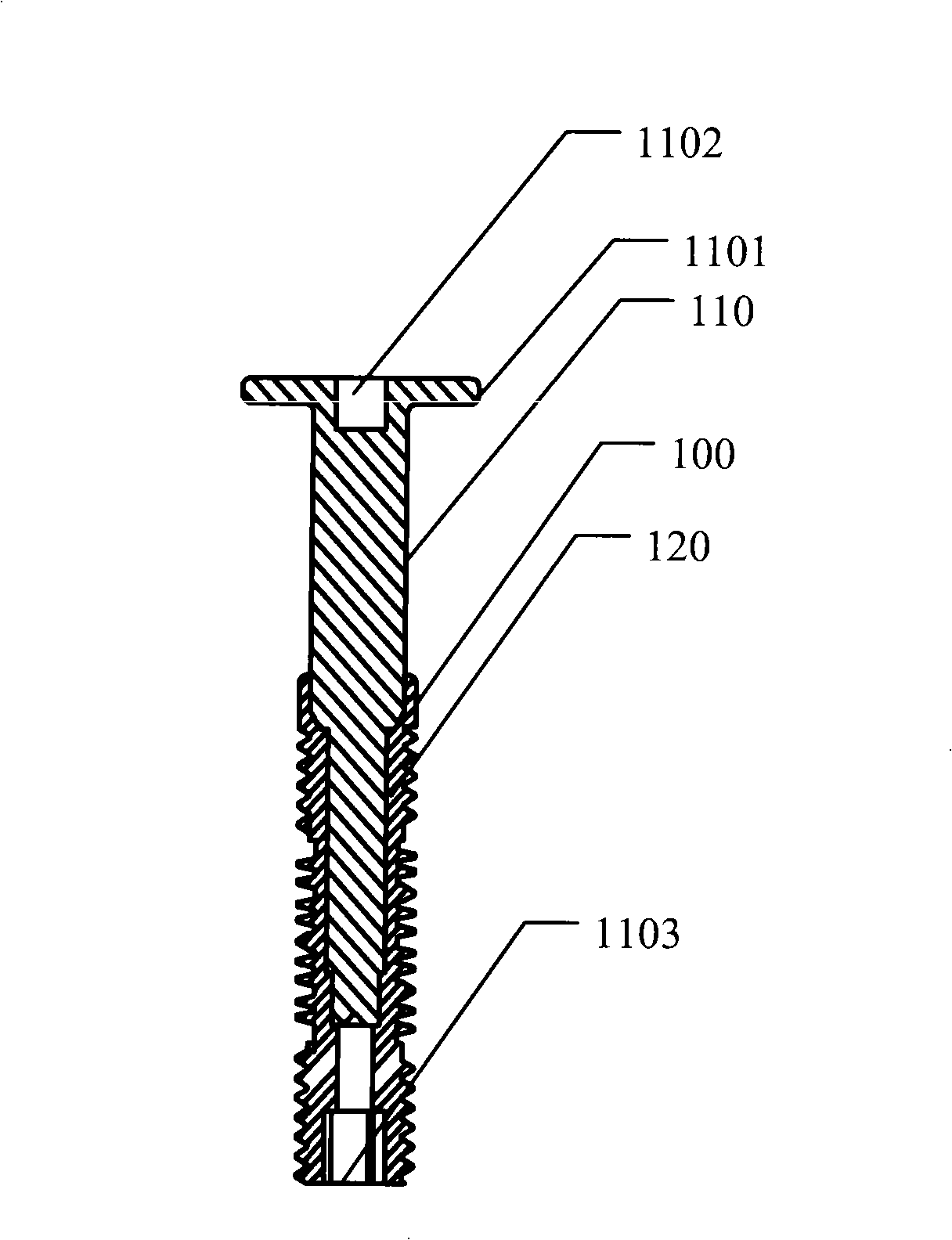

[0015] An embodiment of the present invention provides a screw device, the screw device includes a screw rod and a conductive rigid rod fixed to the screw rod; at least part of the screw rod has threads, and in at least one section of the screw rod having a threaded portion, The pitch of at least one pair of adjacent threads is not equal to the pitch of other adjacent threads. And correspondingly, a cavity filter is also provided, the cavity filter includes at least one cavity, and the cavity is provided with a threaded hole that cooperates with the screw device, and the screw device Adjustably fits in the threaded hole. By changing the pitch of the thread, the purpose of self-locking is realized, and the screw device will not exceed the cavity, nor will the thickness of the filter be increased.

[0016] The recommended embodiments of the screw device provided by the present invention and the cavity filter using the screw device will be described in detail below with referenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com