Battery pole piece, preparation method of battery pole piece, and battery

A battery pole piece and battery technology, applied in electrode manufacturing, battery electrodes, electrode collector coating, etc., can solve problems such as battery safety and over-temperature protection that cannot be fundamentally solved, and reduce the probability of thermal runaway. , the effect of increasing internal resistance and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

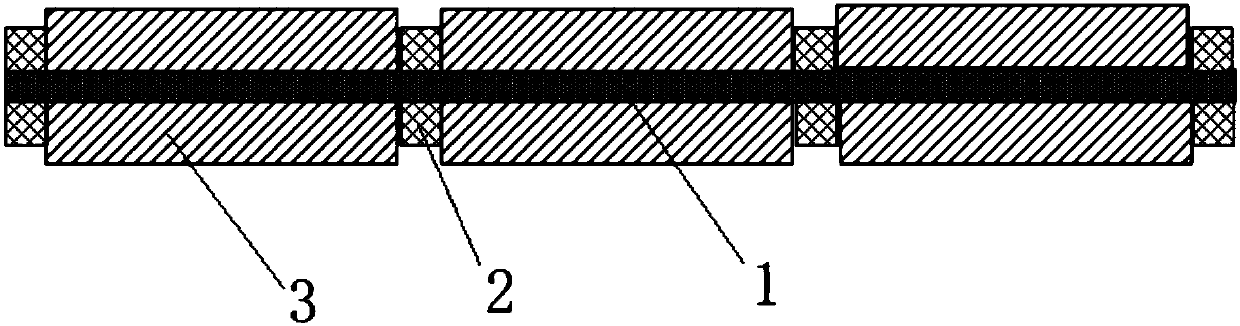

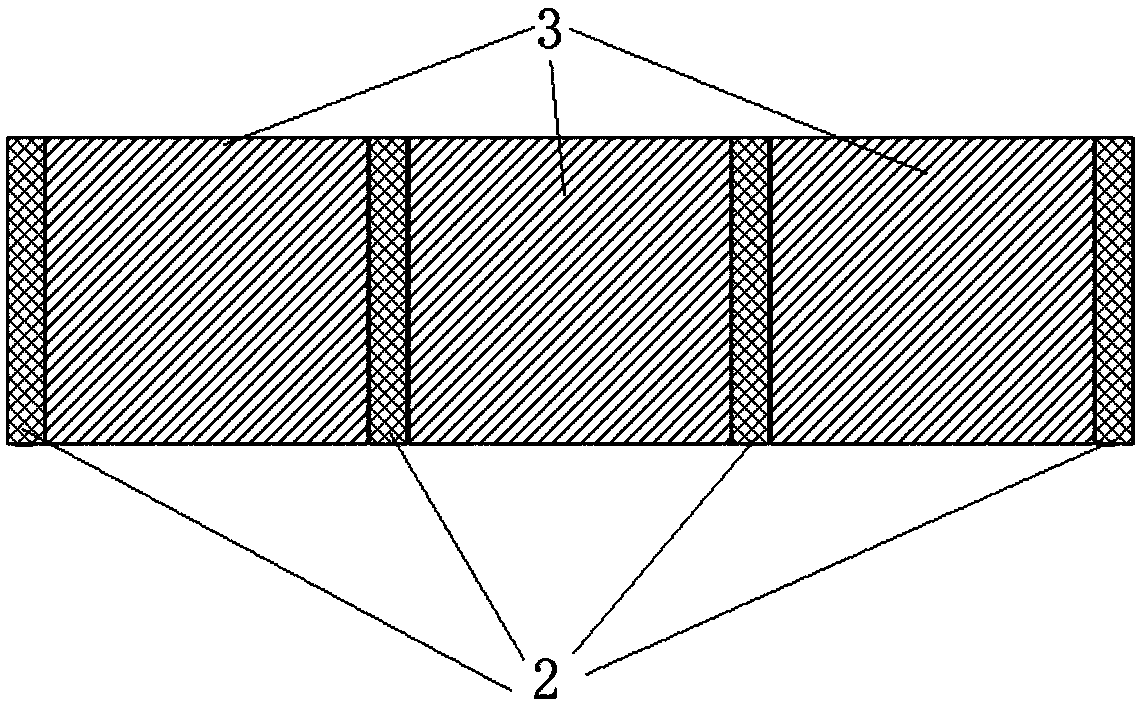

[0045] This embodiment provides a battery pole piece, specifically, such as figure 1 and figure 2 As shown, the battery pole piece in this embodiment includes a current collector 1, an active material coating 3 and a PTC material coating 2; wherein, the surface of the current collector 1 includes a first region and a second region; the first region is coated with an active Material coating 3, the second area is coated with PTC material coating 2.

[0046] Here, the battery pole piece provided in this embodiment introduces the PTC material into the electrode material by dividing the surface of the current collector into the first area coated with the active material coating 3 and the second area coated with the PTC material coating 2 In the diaphragm, when the battery temperature is too high, the PTC material coating can increase the internal resistance of the battery in time, reduce the probability of thermal runaway, and improve the safety performance of the battery. In ad...

Embodiment 2

[0056] Preferably, this embodiment is used to prepare the battery electrode sheet preparation method described in Example 1, which mainly includes the following steps:

[0057] 1. Add binder, positive temperature type material, and conductive agent into the set solvent according to the weight ratio of (1-3):(6-9):(1-4) to prepare PTC material slurry.

[0058] Preferably, in this step, the solid content of the PTC slurry is 30-60%. If it is higher than this range, the fluidity of the slurry will be poor, resulting in uneven coating and tailing. If it is lower than this range , the slurry will be too thin, needle-like tailing will appear and the energy density of the battery will decrease. The solvent is set to be an organic solvent; specifically, a volatile solvent, preferably: N-methylpyrrolidone.

[0059] Preferably, the binder is firstly added to the set solvent, and then the positive temperature type material and the conductive agent are added respectively, and after mixin...

Embodiment 3

[0067] This embodiment provides a battery, wherein the battery in this embodiment includes the battery pole piece described in Example 1; and the battery pole piece is prepared by the method described in Example 2. Preferably, the battery in this embodiment is a lithium ion battery.

[0068] The present invention is further described as follows specifically by experimental embodiment below:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com