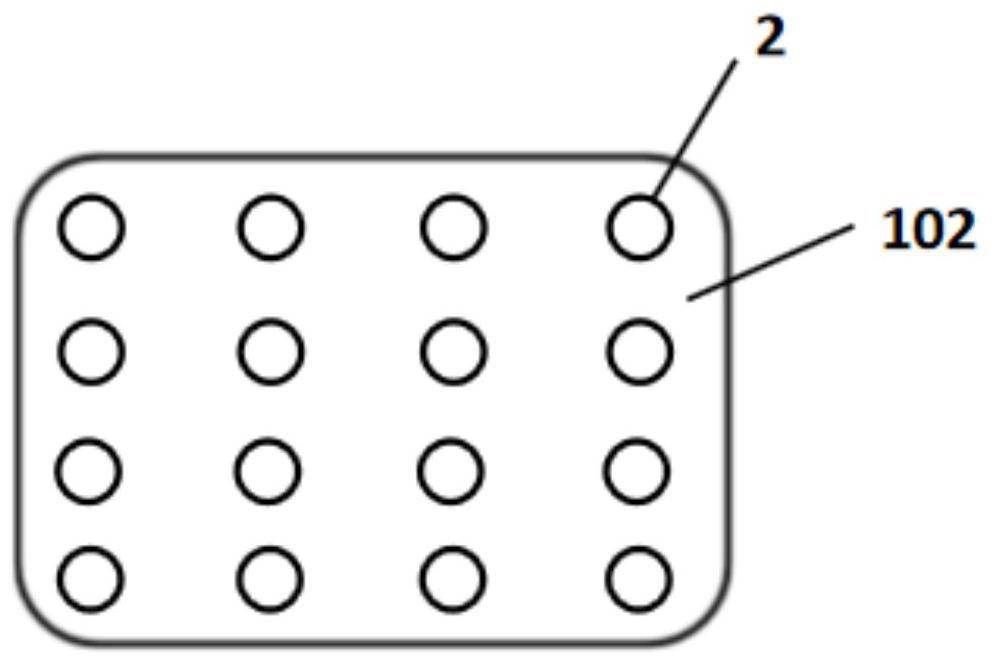

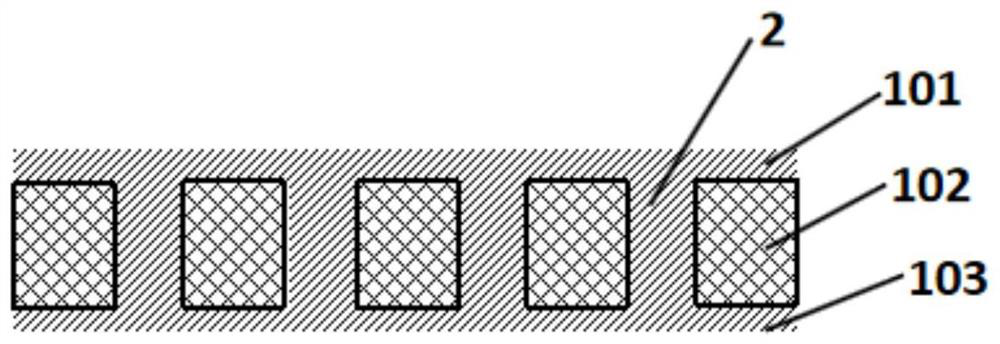

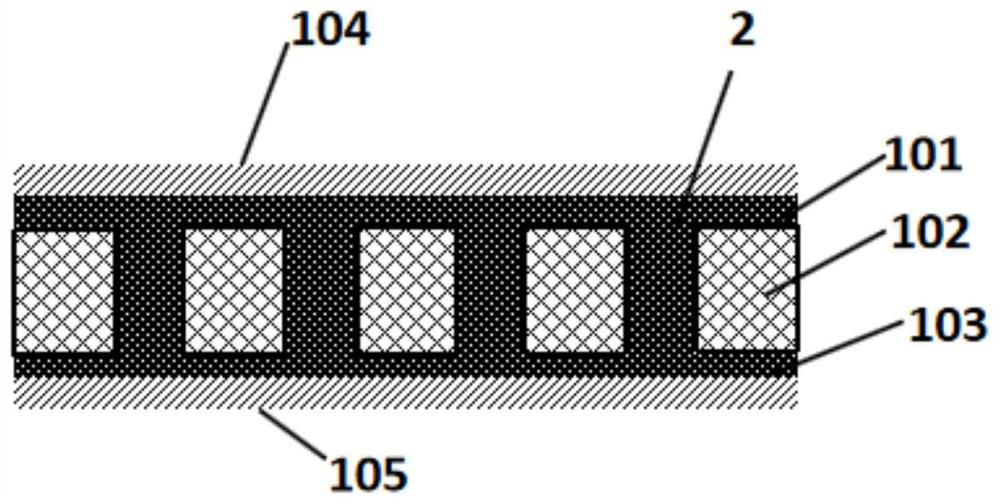

Lithium-supplementing negative pole piece and preparation method thereof and lithium ion battery

A negative electrode pole piece, lithium ion technology, applied in the lithium supplement negative pole piece and its preparation, lithium ion battery field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Negative electrode active material (a mixture of graphite and silicon, capacity C 负 =500mAh g -1 , first coulombic efficiency ICE=80%), pre-lithiated design capacity C 设 It is 90% of the irreversible capacity of the silicon-carbon negative electrode, and the surface density of the pole piece ρ 负面 = 20 mg cm -2 , pole piece area S 负面 =82cm 2 , the specific capacity of metal lithium powder is C Li =3600mAh g -1 , the mass M of lithium metal powder required can be accurately calculated according to the amount of lithium supplemented in the negative electrode Li = ρ 负面 *S 负面 *C 负 *(100%-ICE)*90% / C Li , namely M Li = 20 mg cm -2 *82cm 2 *500mAhg -1 *(100%-80%)*90% / 3600mAh g -1 = 41 mg;

[0035] (2) According to the ratio of metal lithium powder 96.5%, electronic good conductor and lithium ion good conductor compound 2% (1% electronic good conductor, 1% lithium ion good conductor) and binder 1.5%, prepare lithium supplement slurry, Mix 41mg of lithium met...

Embodiment 2

[0041] (1) Negative electrode active material (a mixture of graphite and silicon, capacity C 负 =500mAh g -1 , first coulombic efficiency ICE=80%), pre-lithiated design capacity C 设 It is 100% of the irreversible capacity of the silicon carbon negative electrode, and the surface density ρ of the pole piece 负面 = 20 mg cm -2 , pole piece area S 负面 =82cm 2 , the specific capacity of metal lithium powder is C Li =3600mAh g -1 , the mass M of lithium metal powder required can be accurately calculated according to the amount of lithium supplemented in the negative electrode Li = ρ 负面 *S 负面 *C 负 *(100%-ICE)*100% / C Li , namely M Li = 20 mg cm -2 *82cm 2 *500mAh g -1 *(100%-80%)*100% / 3600mAh g -1 = 45.5 mg;

[0042] (2) According to the ratio of metal lithium powder 96.5%, electronic good conductor and lithium ion good conductor compound 2% (1% electronic good conductor, 1% lithium ion good conductor) and binder 1.5%, prepare lithium supplement slurry, Mix 45.5mg of lit...

Embodiment 3

[0048] (1) Negative electrode active material (a mixture of graphite and silicon, capacity C 负 =500mAh g -1 , first coulombic efficiency ICE=80%), pre-lithiated design capacity C 设 It is 100% of the irreversible capacity of the silicon carbon negative electrode, and the surface density ρ of the pole piece 负面 = 20 mg cm -2 , pole piece area S 负面 =82cm 2 , the specific capacity of metal lithium powder is C Li =3600mAh g -1 , the mass M of lithium metal powder required can be accurately calculated according to the amount of lithium supplemented in the negative electrode Li = ρ 负面 *S 负面 *C 负 *(100%-ICE)*100% / C Li , namely M Li = 20 mg cm -2 *82cm 2 *500mAh g -1 *(100%-80%)*100% / 3600mAh g -1 = 45.5 mg;

[0049] (2) According to the ratio of 95% lithium metal powder, good electron conductor and lithium ion good conductor compound 3% (2% electron good conductor, 1% lithium ion good conductor) and binder 2%, the lithium supplement slurry is prepared, Mix 45.5mg of lit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Via hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com