Semi-solid lithium flow battery reactor, battery system and working method

A flow battery and semi-solid technology, applied in fuel cells, electrochemical generators, regenerative fuel cells, etc., can solve problems such as serious polarization, increased battery internal resistance, and battery short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

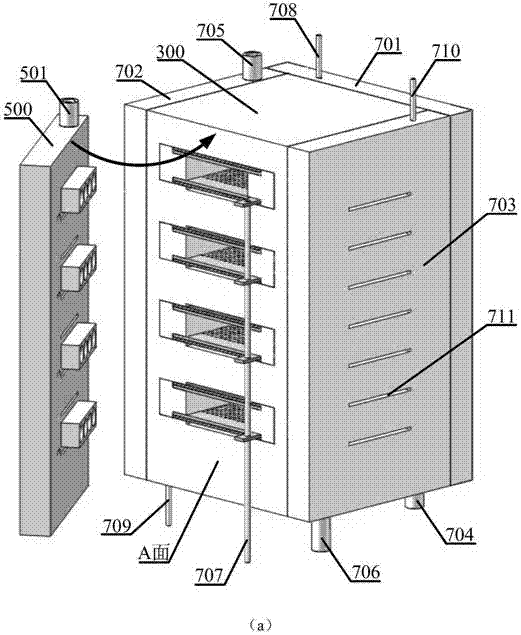

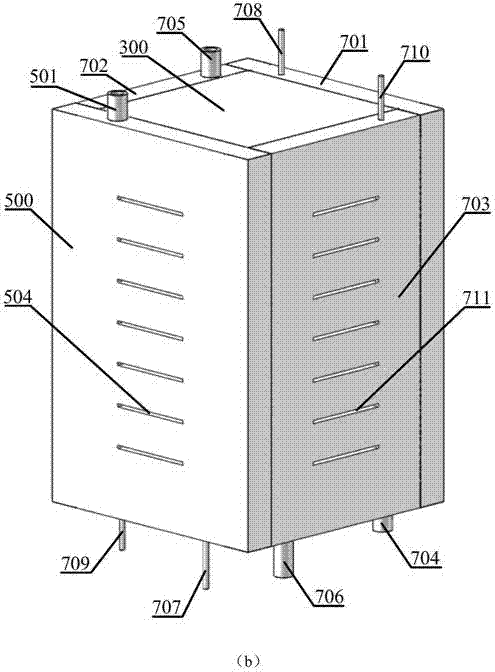

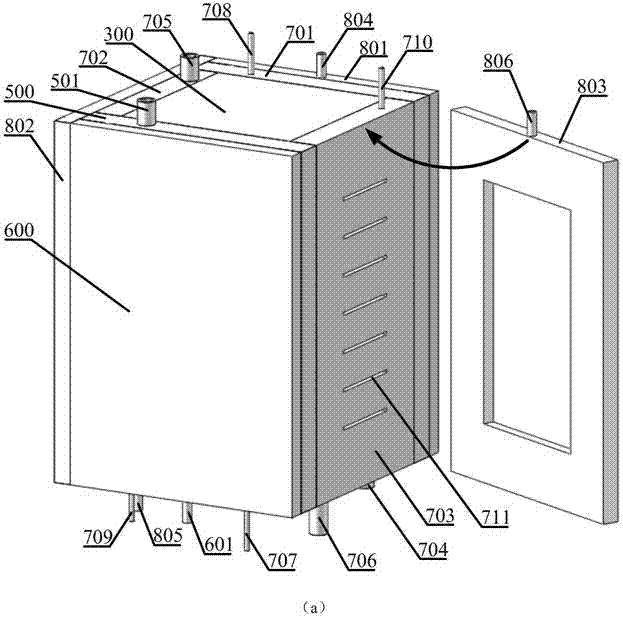

[0054] In this embodiment, a semi-solid lithium flow battery reactor 900 is provided, including a battery frame 400, a positive cavity 200, a negative cavity 401, a positive manifold 801, a positive manifold 802, a negative manifold 803, a negative manifold 804, Positive electrode liquid inlet 805, positive electrode liquid outlet 806, negative electrode liquid inlet 807, negative electrode liquid outlet 808, first positive electrode guide rod 809, second positive electrode guide rod 810, first negative electrode guide rod 811, second Negative guide rod 812 , first flow distribution cavity 901 ; second flow distribution cavity 902 ; first confluence cavity 903 ; second flow confluence cavity 904 .

[0055] The positive electrode cavity 200 includes two layers of porous positive electrode current collectors 103 with the same polarity, a separator 101, and two insulators 201. An insulator 201 is arranged between the edges of the two layers of porous positive electrode current col...

Embodiment 2

[0066] In this embodiment, several cavity heights of the positive electrode cavity 200, the negative electrode cavity 401 and the isolation cavity 102 are provided, as shown in Table 1:

[0067] Table 1 Cavity Heights of Positive Electrode Chamber 200, Negative Electrode Chamber 401, and Isolation Chamber 102

[0068] serial number

[0069] Other content of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0071] In this embodiment, several types of materials for the separator 101, the porous positive electrode collector 103 and the porous negative electrode collector 104 are provided, as shown in Table 2:

[0072] Table 2 Composition of separator, porous positive current collector and porous negative current collector material

[0073]

[0074] Other content of this embodiment is the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com