Display panel and mother board thereof

A technology for display panels and display areas, applied in static indicators, organic semiconductor devices, optics, etc., can solve problems such as damage to active components and/or passive components, peeling, and decrease in reliability of display panels, and achieve improved reliability, The effect of improving tensile strength, avoiding metal wire breakage or substrate damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

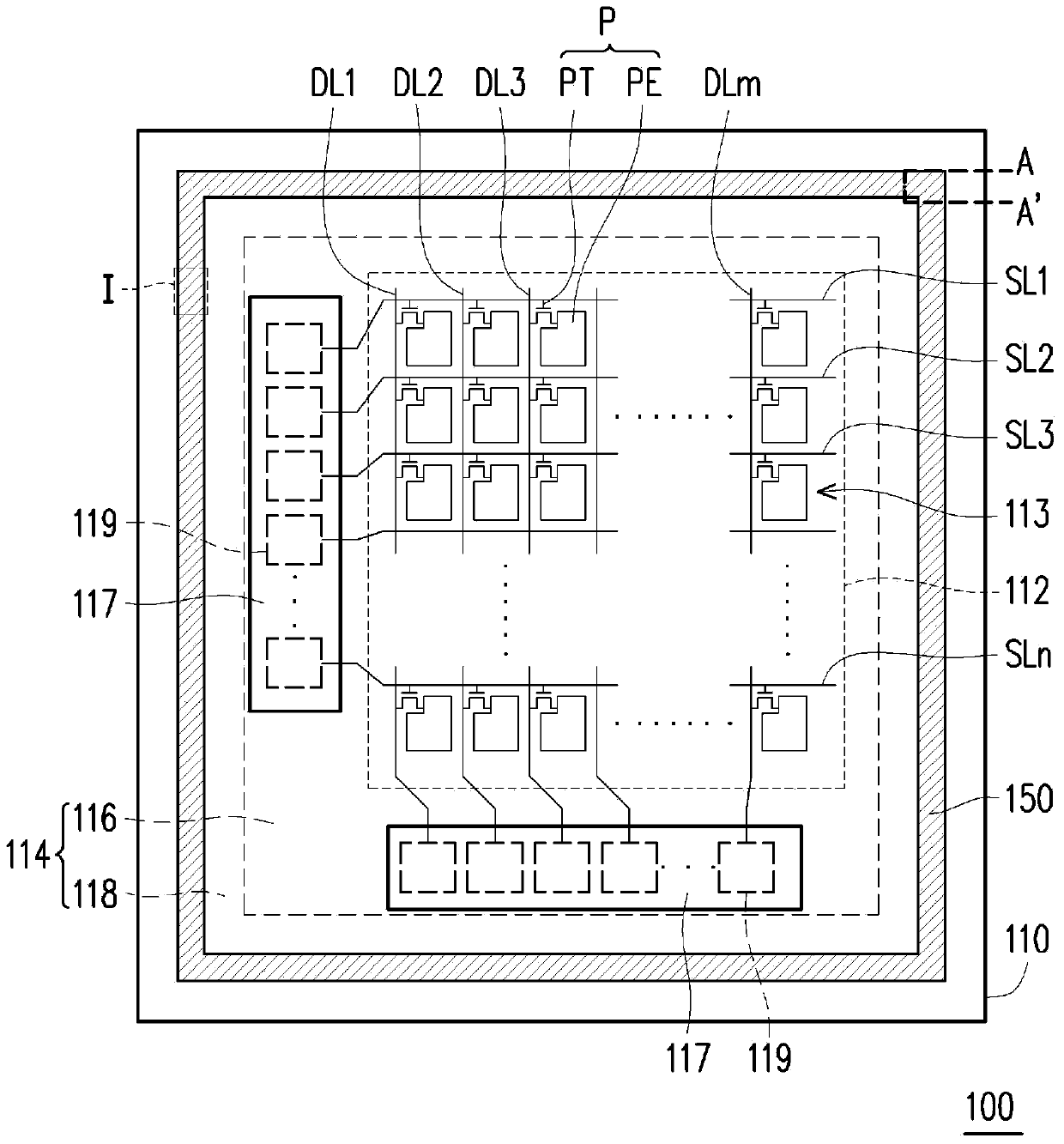

[0100] Figure 8 is a cross-sectional view of a part of the outer area of the display panel according to the first embodiment of the present invention, wherein Figure 8 along figure 2 The cross-sectional view taken by the line A-A'. Please also refer to figure 2 and Figure 8 The outer area 118 of the display panel 100 may include the substrate 110 , the buffer layer 120 , the semiconductor layer 130 , the insulating layer 140 and the metal wall 150 . The material of the substrate 110 can be organic polymer, glass, quartz, or opaque / reflective material (for example: conductive material, metal, wafer, ceramic, or other applicable materials), or other applicable materials .

[0101] The buffer layer 120 can be disposed on the substrate 110 and can be an inorganic thin film made of inorganic materials. For example, the buffer layer 120 can be an inorganic film made of silicon oxide and silicon nitride, and its thickness can be about 350 nanometers (nm), wherein the thi...

no. 2 example

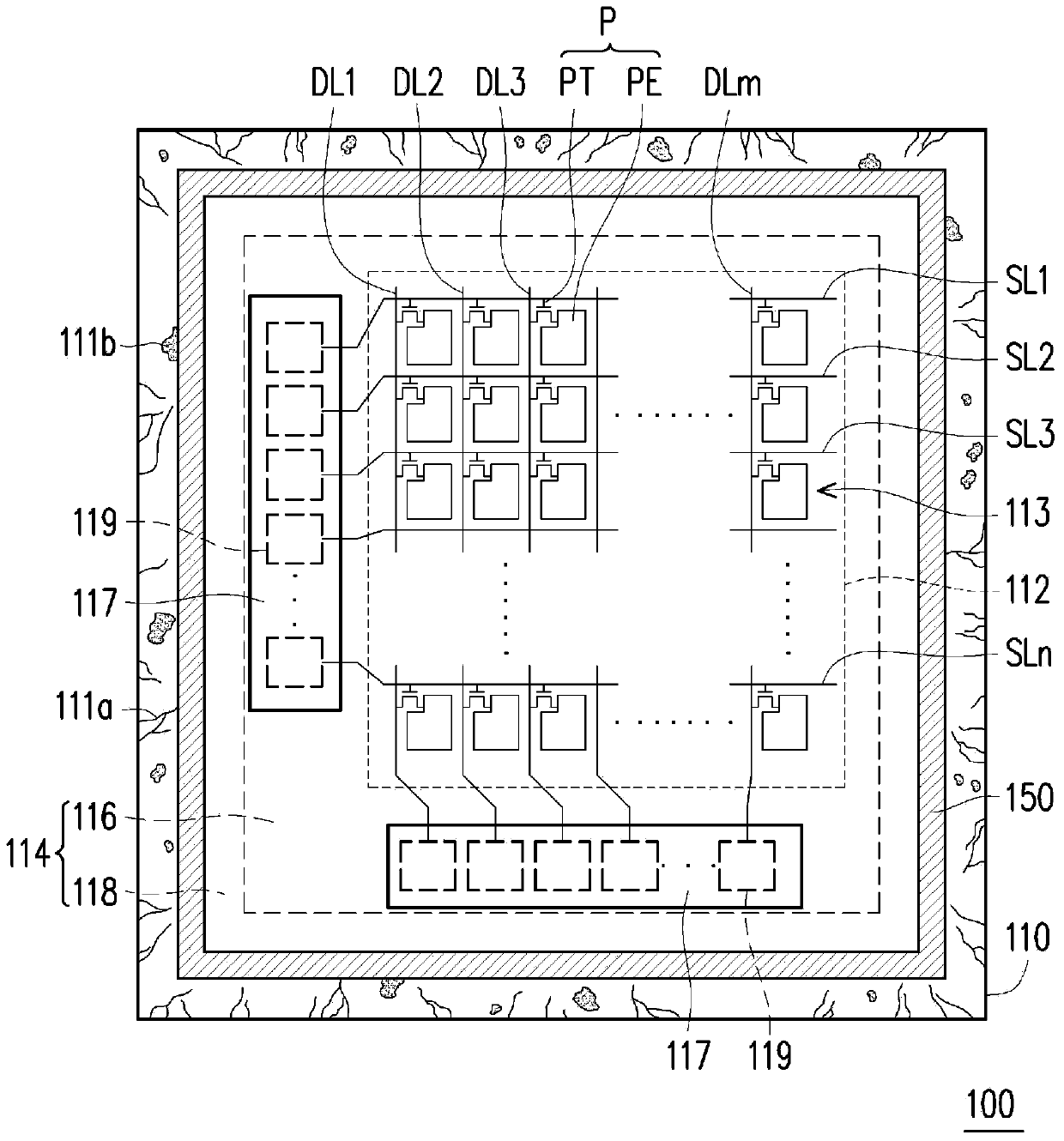

[0107] Figure 9 is a cross-sectional view of a part of the outer area of the display panel according to the second embodiment of the present invention. Please also refer to Figure 8 and Figure 9 The structure of the display panel 200 of the second embodiment is similar to that of the first embodiment, but the difference between them is that the metal wall 250 in the display panel 200 is directly disposed on the buffer layer 120 . In other words, in the outer area of the display panel 200, the buffer layer 120 can be directly disposed on the substrate 110 as an insulating layer without additionally disposing a semiconductor layer and an additional insulating layer, so the metal wall 250 can be directly disposed as an insulating layer. layer on buffer layer 120. It is worth mentioning that since the buffer layer 120 can generally be an inorganic thin film made of inorganic materials and has electrical insulation properties, when the metal wall 250 is directly disposed ...

no. 3 example

[0109] Figure 10 is a cross-sectional view of a part of the outer area of the display panel according to the third embodiment of the present invention. Please also refer to Figure 8 and Figure 10 The structure of the display panel 300 of the third embodiment is mostly the same as that of the first embodiment, but the difference between the two is that the metal wall 350 of the display panel 300 is a multi-layer metal stack structure.

[0110] Please refer to Figure 10 For example, the metal wall 350 can be a metal stack structure composed of a metal layer 350a, a metal layer 350b and a metal layer 350c, wherein the metal layer 350a / metal layer 350b / metal layer 350c can be, for example, Ti / Al / Ti or Mo / Al / Mo multilayer metal stack structure. It is worth mentioning that, as long as the average Poisson's ratio of all metal layers in the metal wall 350 is greater than 0.32, the metal wall 350 may also include a metal layer (such as Mo) whose Poisson's ratio is less than ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com