Displaying device and displaying substrate

A technology for display substrates and display devices, applied in identification devices, instruments, etc., can solve the problems of reducing crack prevention, low product yield, and unclean etching of inorganic substances, so as to improve product yield and prevent the extension of cracks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

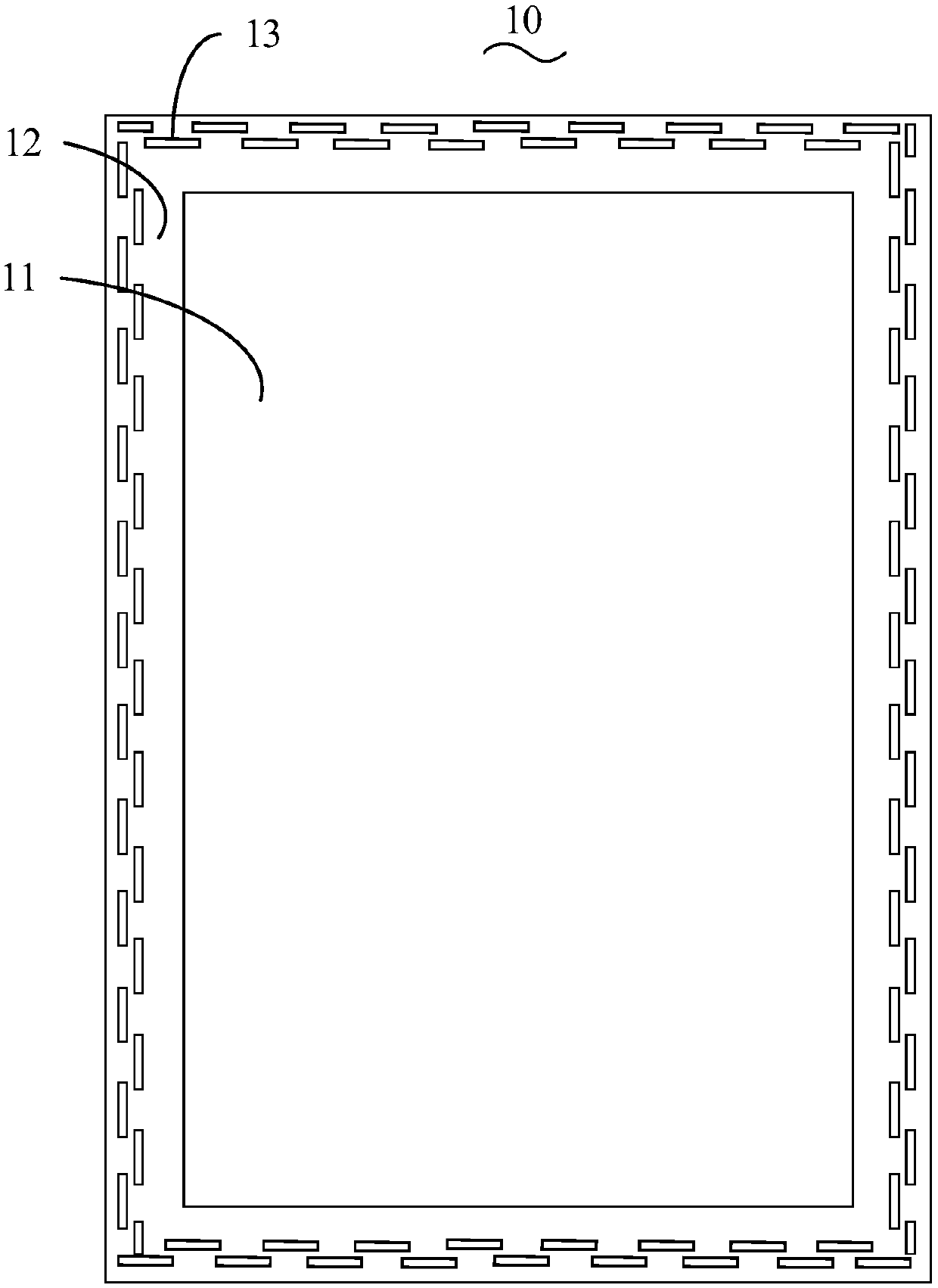

[0015] Such as figure 1 as shown, figure 1 is a schematic structural view of the display substrate according to the first embodiment of the present invention. In this embodiment, the display substrate 10 includes a display region 11 and a barrier layer 12 .

[0016] The display area 11 is located inside the display substrate 10 , and the barrier layer 12 is located between the display area 11 and the substrate edge of the display substrate 10 . Wherein, the barrier layer 12 is provided with two rows of first hole segments 13 at intervals in the direction from the display area 11 to the edge of the substrate. Each row of first hole segments 13 includes at least two first hole segments 13 arranged at intervals along the extending direction of the edge of the substrate. Moreover, projections of adjacent rows of first hole segments 13 in the extending direction of the substrate edge overlap with each other.

[0017] In this embodiment, the first hole segment 13 is arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com