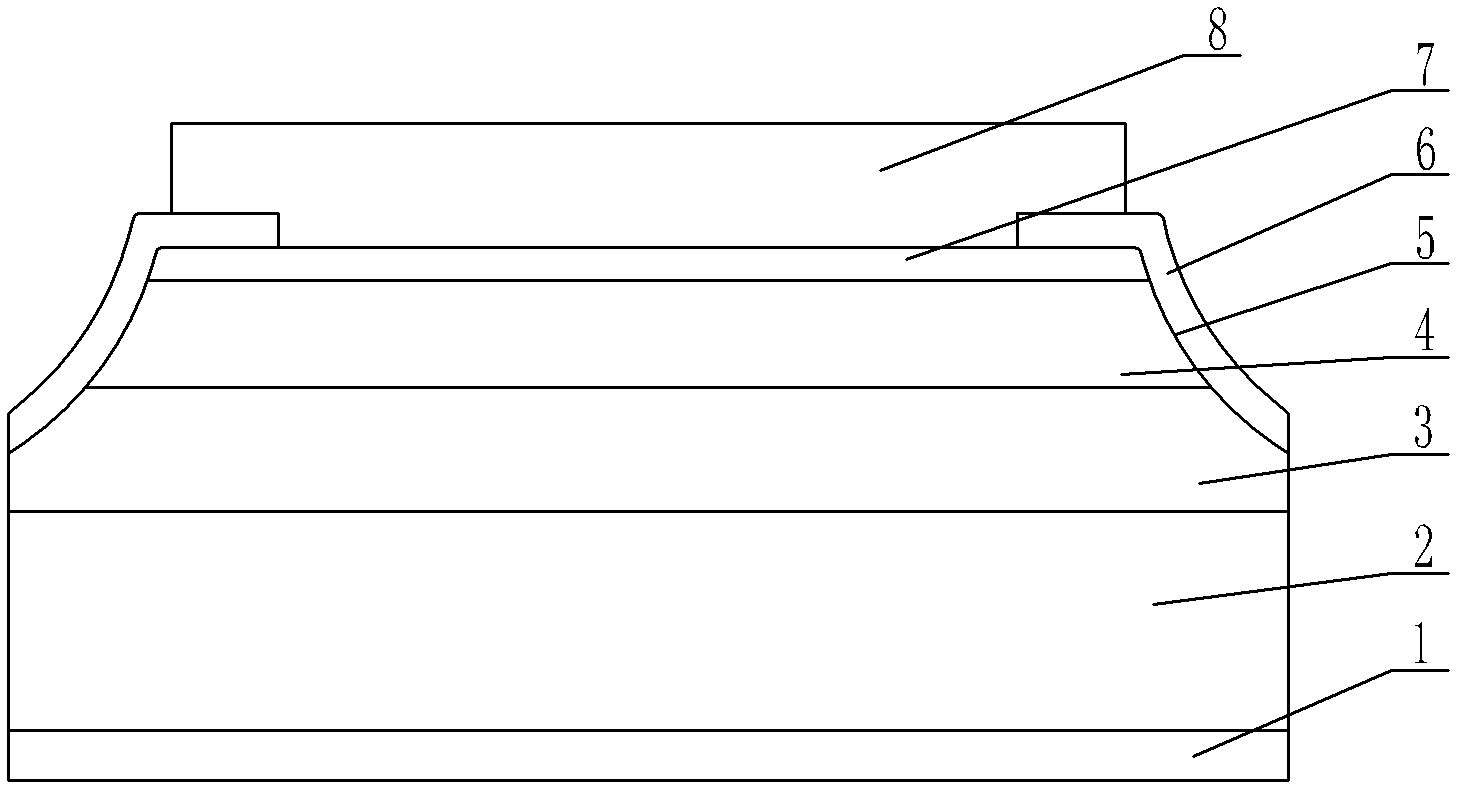

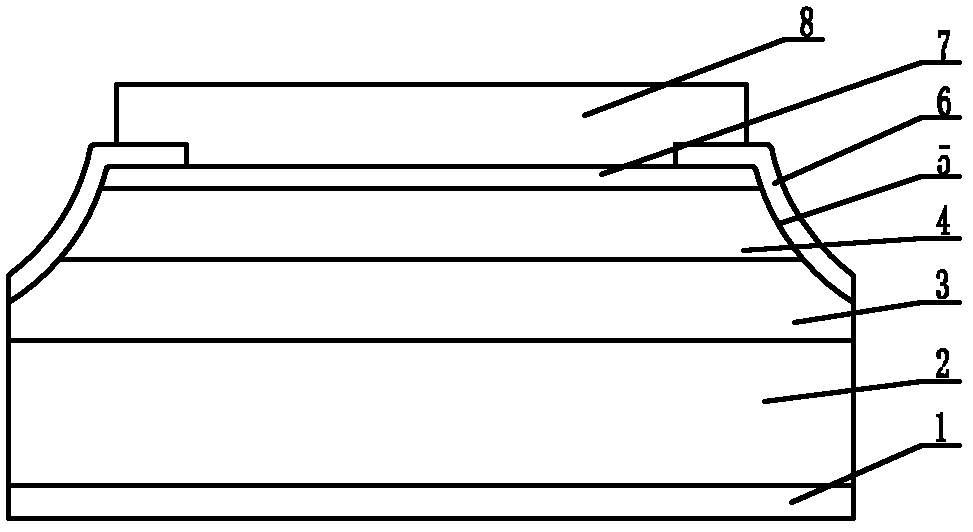

Fast recovery epitaxial diode and preparation method thereof

A diode and epitaxy technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of long process flow, long production cycle, and many manufacturing processes, so as to shorten the process flow, improve ohmic contact, and reduce environmental pollution. pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preparation method of fast recovery epitaxial diode of the present invention, according to the following steps:

[0026] (1) Growth of the first epitaxial layer: grow more than one layer of N-type first epitaxial layer on the front side of the N+ type substrate silicon wafer, the total thickness of which is controlled at 1-300 μm, and the resistivity is 1-150 ohm cm. The thickness of the first N-type epitaxial layer can be controlled at 30-200 μm, and the resistivity is 20-100 ohm centimeters. The N-type epitaxial layer can be grown once, twice or three times, so that the N+ type substrate grown on the front side of the silicon wafer Type of the first epitaxial layer as a drift region.

[0027] (2) Growth of the second epitaxial layer: grow a layer of P-type second epitaxial layer on the first epitaxial layer, its thickness is controlled at 1-30 μm, and the impurity concentration is controlled at 10 13 ~10 18 cm -3 , the thickness can also be controlled at 5-18 μ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com