Paving method of steel box girder bridge deck payment layer

A bridge deck pavement and steel box girder technology, which is applied in bridges, bridge parts, bridge construction, etc., can solve the problems of extremely high environmental temperature and humidity conditions, difficult repair of pavement materials, and harsh construction conditions. Achieve the effect of improving bending and tensile stress and fatigue resistance, interface shear resistance, excellent fatigue performance, and reducing self-weight load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

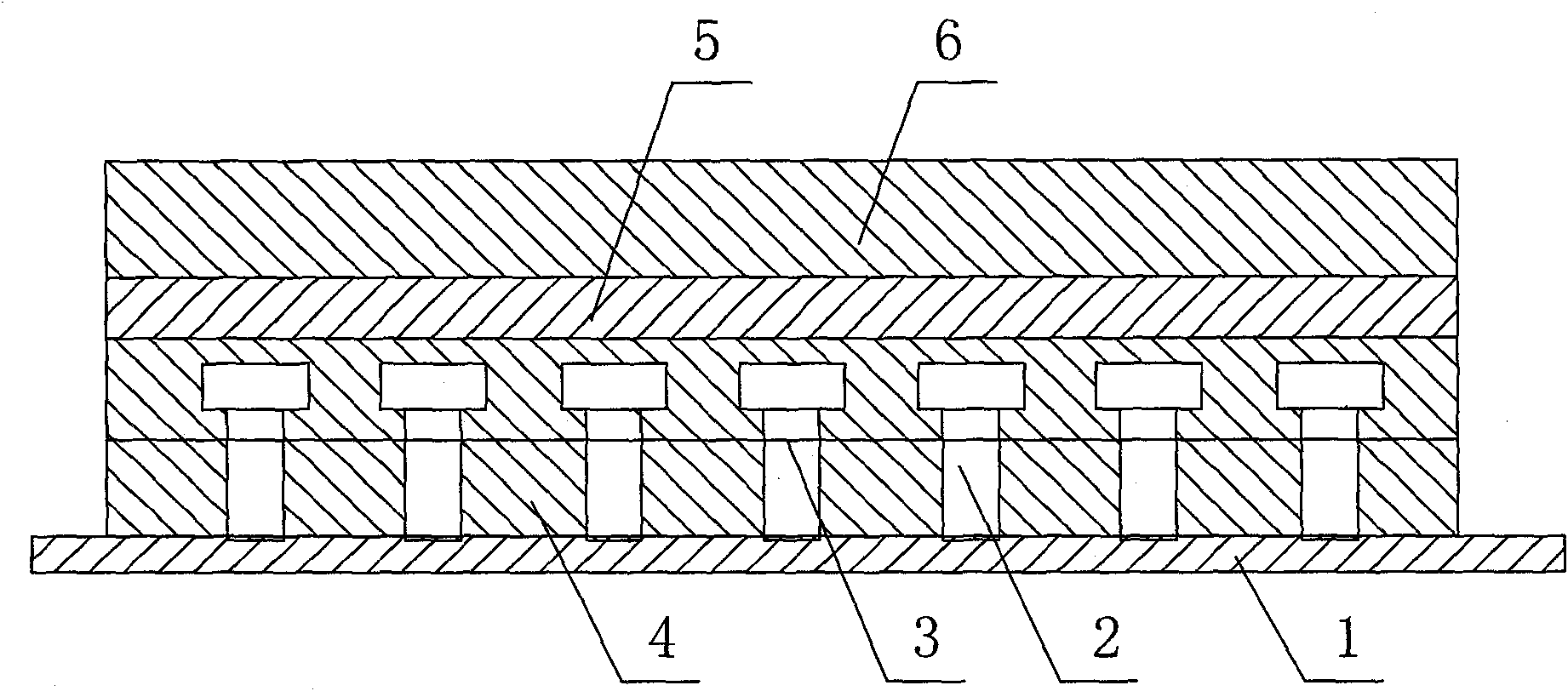

[0067] Such as figure 1 As shown, a method for paving a steel box girder bridge deck pavement includes the following steps:

[0068] 1) Pre-cleaning of bridge deck:

[0069] Clean the steel box girder bridge deck. During the construction process, no vehicles are allowed to pass. Ensure that there is no dirt 15m away from the two ends of the steel box girder to prevent dust from polluting the bridge deck during bridge deck construction;

[0070] 2) Welding shear nails:

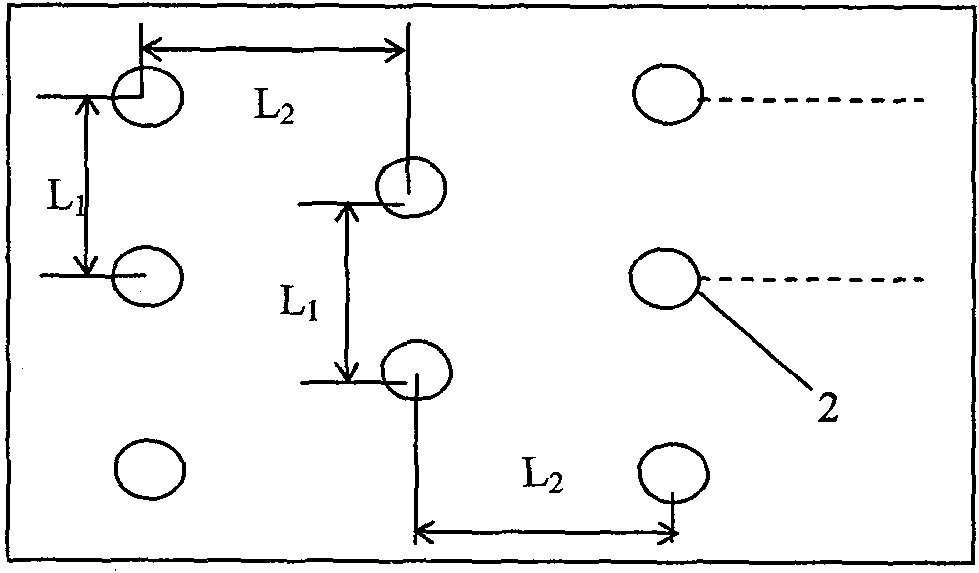

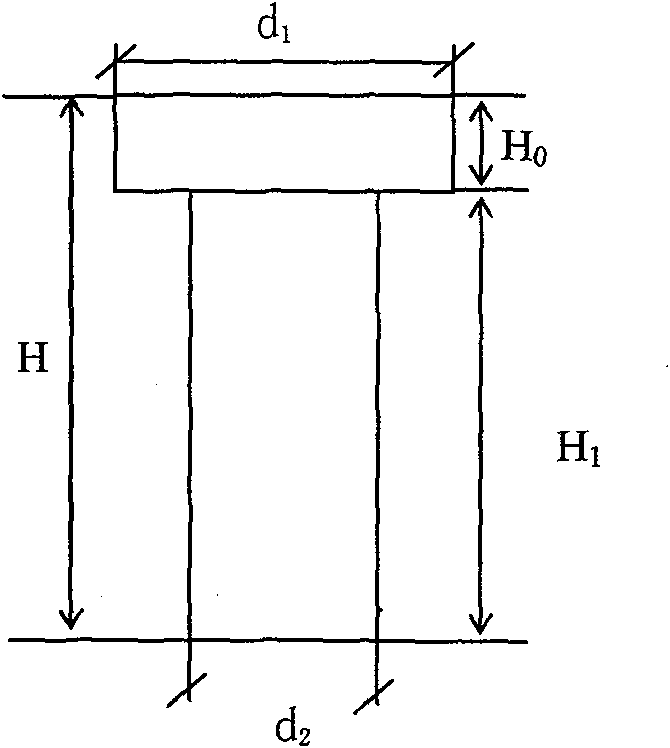

[0071] The material and welding quality requirements of shear nails must meet the standard design and requirements of shear nails (also known as cylindrical head welding nails) in the national standard GB10433-2002 and "Technical Specifications for Highway Bridge and Culvert Construction" JTJ041-2000, and the specifications of the shear nails used Is: the diameter of the nail of the shear nail d 1 =10mm, the diameter d of the cylinder of the shear nail 2 =14mm, the height of the nail head of the shear nail H 0 = 3mm (s...

Embodiment 2

[0123] Such as figure 1 As shown, a method for paving a steel box girder bridge deck pavement includes the following steps:

[0124] 1) Pre-cleaning of bridge deck:

[0125] Sweep the steel box girder bridge deck. During the construction process, no vehicles are allowed to pass. Ensure that there is no soil 15m away from the two ends of the steel box girder to prevent dust from polluting the bridge deck during bridge deck construction;

[0126] 2) Welding shear nails:

[0127] The material and welding quality requirements of shear nails must meet the standard design and requirements of shear nails (also called cylindrical head welding nails) in the national standard GB10433-2002 and "Technical Specifications for Highway Bridge and Culvert Construction" JTJ041-2000, and the specifications of the shear nails used Is: the diameter of the nail of the shear nail d 1 =15mm, the diameter d of the cylinder of the shear nail 2 =18mm, the height of the nail head of the shear nail H 0 = 6mm (see...

Embodiment 3

[0179] Such as figure 1 As shown, a method for paving a steel box girder bridge deck pavement includes the following steps:

[0180] 1) Pre-cleaning of bridge deck:

[0181] Sweep the steel box girder bridge deck. During the construction process, no vehicles are allowed to pass. Ensure that there is no soil 15m away from the two ends of the steel box girder to prevent dust from polluting the bridge deck during bridge deck construction;

[0182] 2) Welding shear nails:

[0183] The material and welding quality requirements of shear nails must meet the standard design and requirements of shear nails (also called cylindrical head welding nails) in the national standard GB10433-2002 and "Technical Specifications for Highway Bridge and Culvert Construction" JTJ041-2000, and the specifications of the shear nails used Is: the diameter of the nail of the shear nail d 1 =12mm, the diameter d of the cylinder of the shear nail 2 =16mm, the height of the nail head of the shear nail H 0 = 4mm (see...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com