High folding resistance road concrete material and preparing method thereof

A concrete and high-bending-resistant technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as fuzzy qualitative evaluation, decreased homogeneity, improper use of cementitious materials, etc., to achieve frost resistance The effect of improving melting and impermeability, improving mechanical properties and durability, and reducing the rate of intrusion into the matrix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

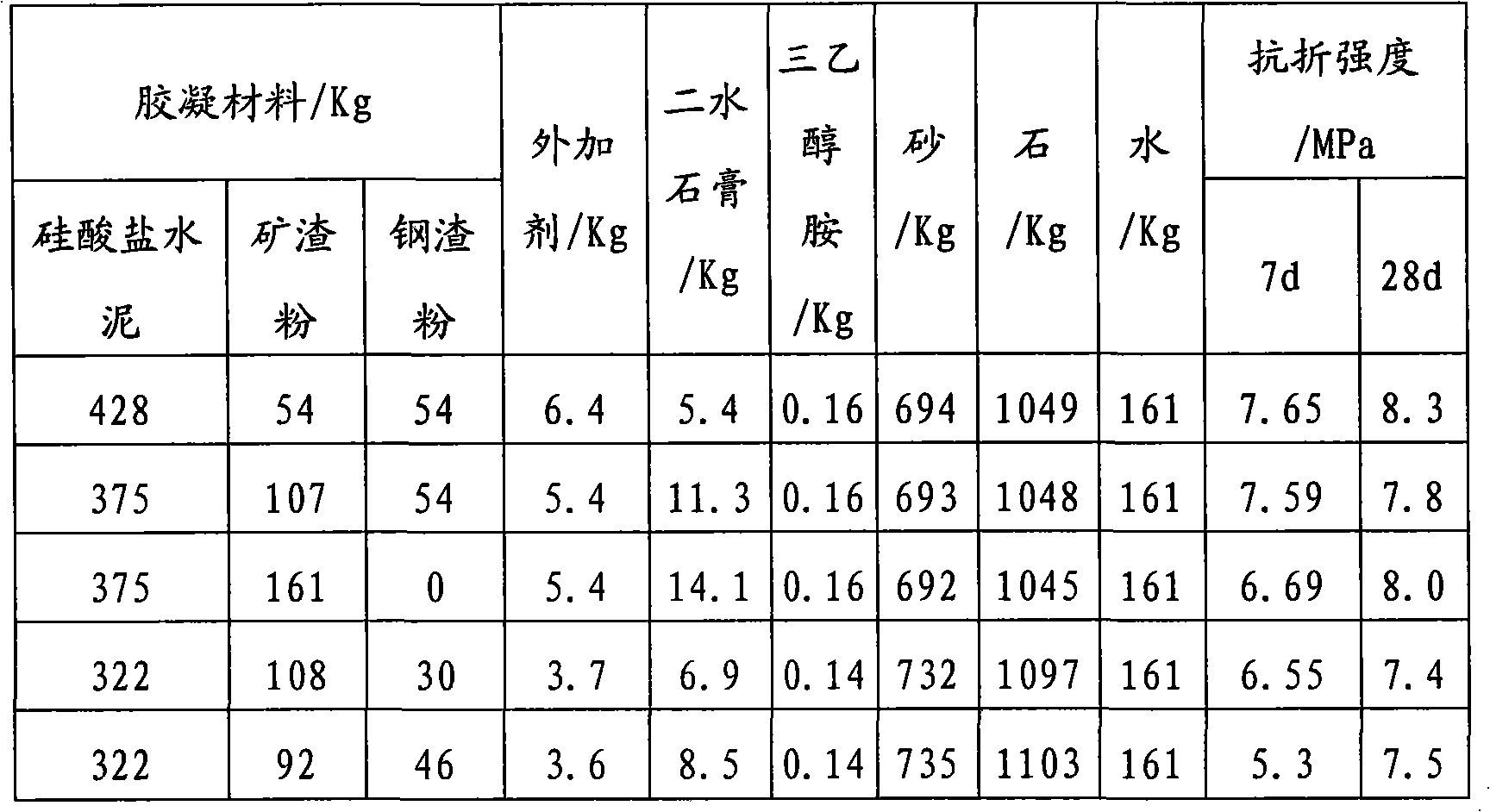

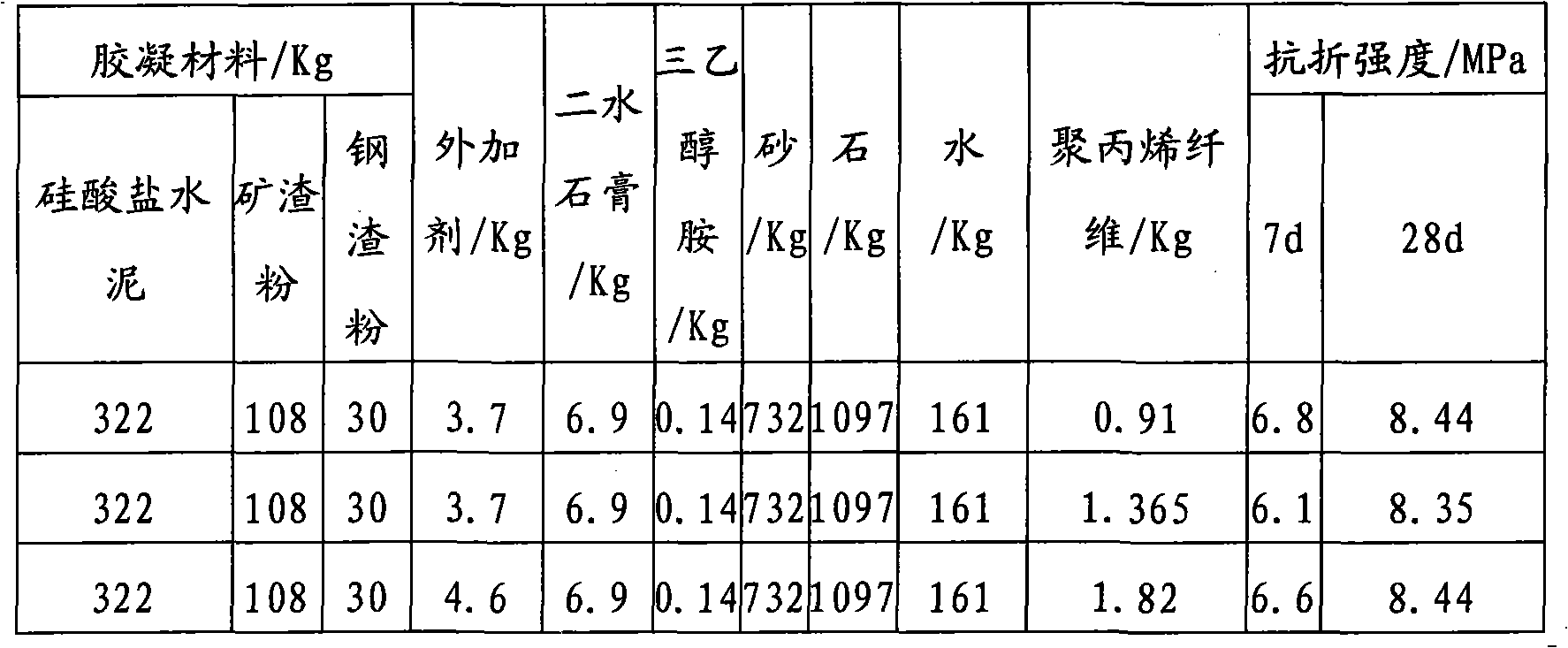

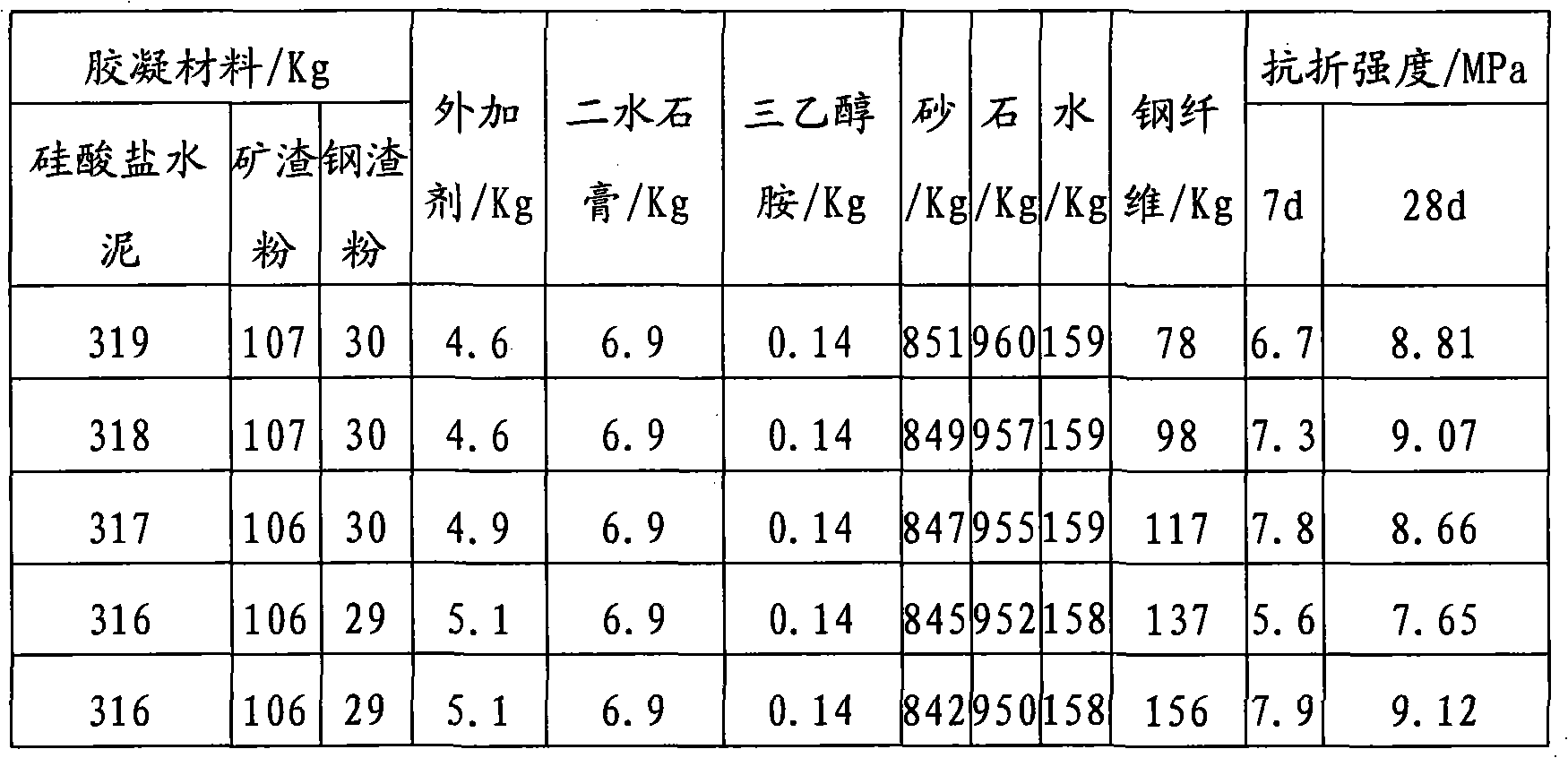

Examples

preparation example Construction

[0030] The preparation method of high flexure-resistant road concrete material of the present invention comprises the steps:

[0031] 1) Carry out the compatibility test of the pre-prepared concrete admixture with the slurry fluidity method, and confirm that the slurry has good initial fluidity and small fluidity loss over time, and has no hardening and no bleeding;

[0032] 2) Add the weighed stone, sand, cementitious material, and fiber into the forced mixer in turn, and dry stir for 1 to 2 minutes to fully disperse the material (fiber);

[0033] 3) Add one-half of the total mixing water and admixture (mix water and admixture first) into the mixer, and stir for 1 minute to make the cementitious material wrap the sandstone aggregate and fiber;

[0034] 4) Add the remaining water and admixture, mix the materials evenly, pour them out of the mixer, and vibrate properly for casting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com