Long glass fiber-nylon resin composition and preparation method thereof

A nylon resin and composition technology, which is applied in the field of long glass fiber nylon resin composition and its preparation, can solve the problems of easy corrosion by acid and alkali, weak heat resistance, oxidation, etc., and achieves low equipment requirements and good rigidity , the effect of simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

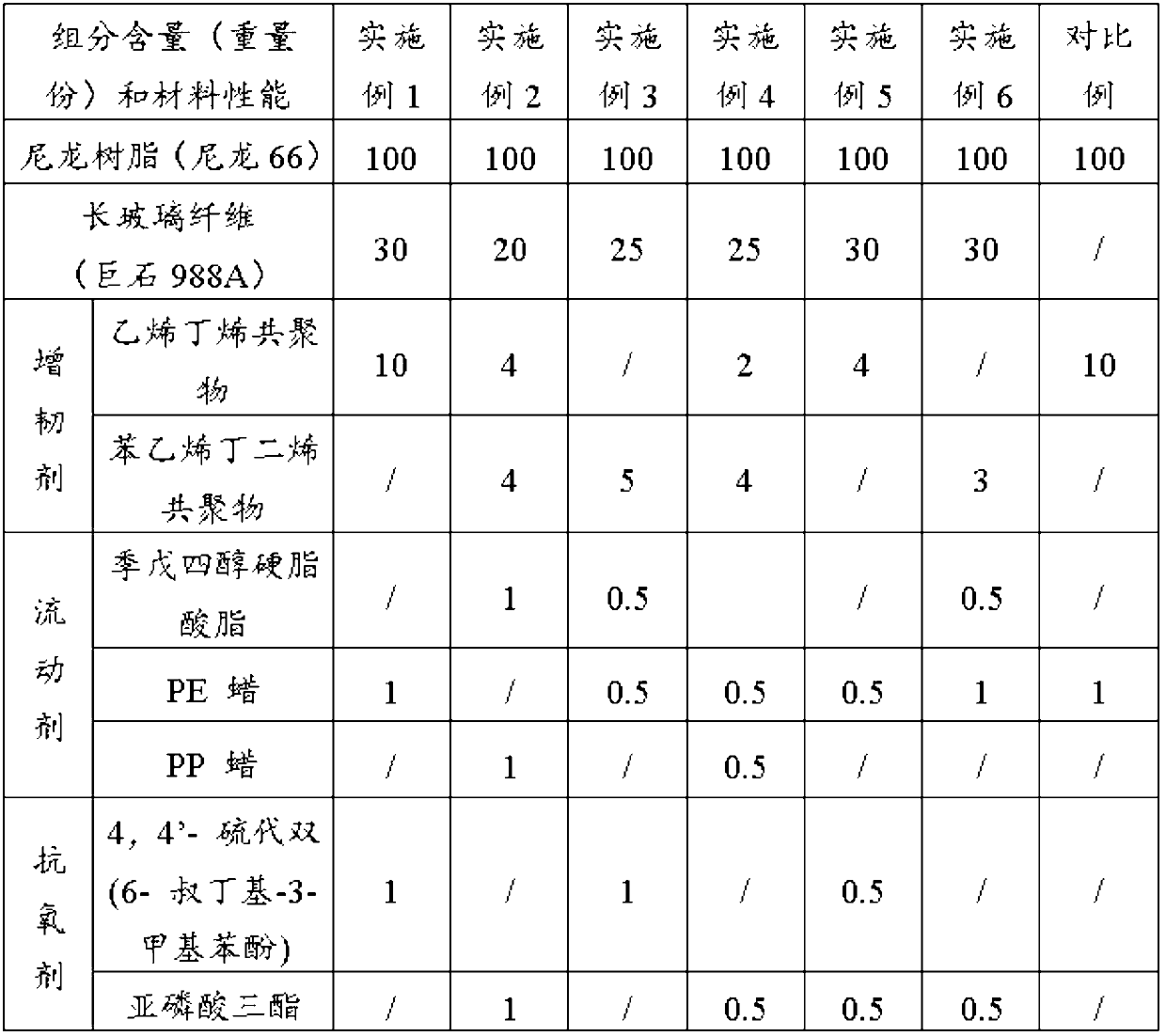

[0022] The content of the components involved in this embodiment is given according to the content specified in Table 1.

[0023] Step 1. Add nylon resin, toughening agent, flow agent, and antioxidant into the mixer, and stir to form a uniform first mixture, and dry the first mixture at a temperature of T1 for 4-6 hours .

[0024] Step 2, adding the first mixture into a twin-screw extruder, controlling the screw speed and the temperature of the twin-screw extruder; The glass fiber and the first mixture are at a screw speed of V, and the temperature of the first zone of the twin-screw extruder is T2, the temperature of the second zone is T3, the temperature of the third zone is T4, the temperature of the fourth zone is T5, and the temperature of the fifth zone is T6. Melting under conditions, mixing uniformly, extruding, stretching, cooling, air-drying, and pelletizing to obtain long glass fiber nylon resin composition particles.

[0025] The long glass fiber nylon resin comp...

Embodiment 2

[0027] The method of Example 1 was repeated according to the content of each component specified in Table 1, and the properties of the long glass fiber nylon resin composition particles prepared in this example were measured according to the standards described in Table 1. See Table 1 for the measurement results.

Embodiment 3

[0029] The method of Example 1 was repeated according to the content of each component specified in Table 1, and the properties of the long glass fiber nylon resin composition particles prepared in this example were measured according to the standards described in Table 1. See Table 1 for the measurement results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com