Heat insulating body and manufacturing method thereof

A manufacturing method and a technology for a thermal insulation body, which are applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as inability to achieve use effects, and achieve excellent anti-aging, high temperature resistance and high effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

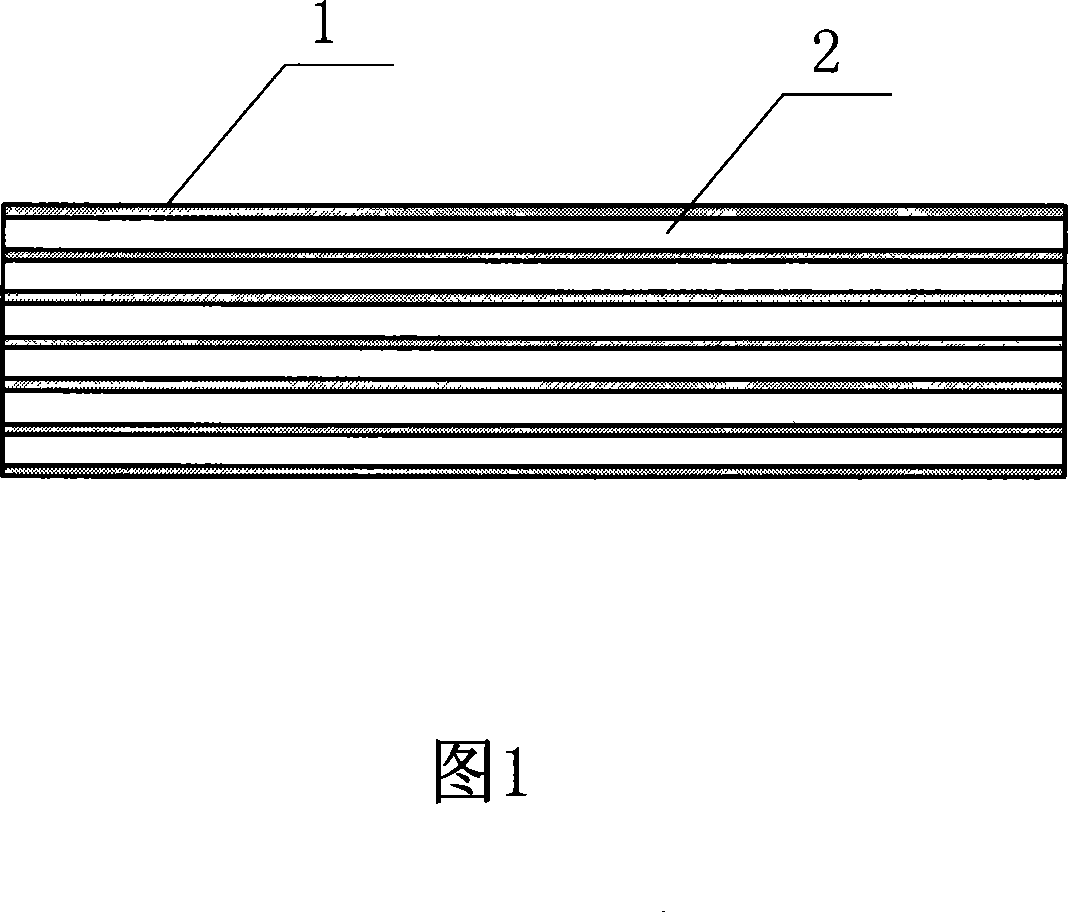

[0013] a. As shown in FIG. 1 : there is a slurry layer 1 between the fiber layers 2 .

[0014] The raw material composition of the slurry layer: 20 parts of rock wool, 65 parts of sepiolite, 2 parts of polyvinyl alcohol, 1.5 parts of rare earth composite adhesive, 20 parts of bentonite, 20% of hollow ceramic powder and 80% of porous ceramic particles by weight 1.5m 3 mix.

[0015] b. Slurry preparation process: mix polyvinyl alcohol, rare earth composite adhesive and bentonite, add hot water and stir to form slurry, add rock wool, sepiolite, hollow ceramic powder and porous ceramic particles to the slurry In the material, stir to mix, and reconcile with water to form a paste.

[0016] c. Manufacture of thermal insulation body: Lay a layer of fiber layer on the object that needs thermal insulation, coat the slurry on the fiber layer, and then lay a fiber layer on the slurry to form a layer of thermal insulation body, which can be laid layer by layer according to needs With c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com