Method for producing compound modified bitumen

A technology of composite modified asphalt and a production method, applied in the production field of composite modified asphalt, can solve the problems of strong adhesion, poor aging resistance and oxidation resistance, low temperature sensing performance, etc., so as to improve the anti-aging and paving performance. Good and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

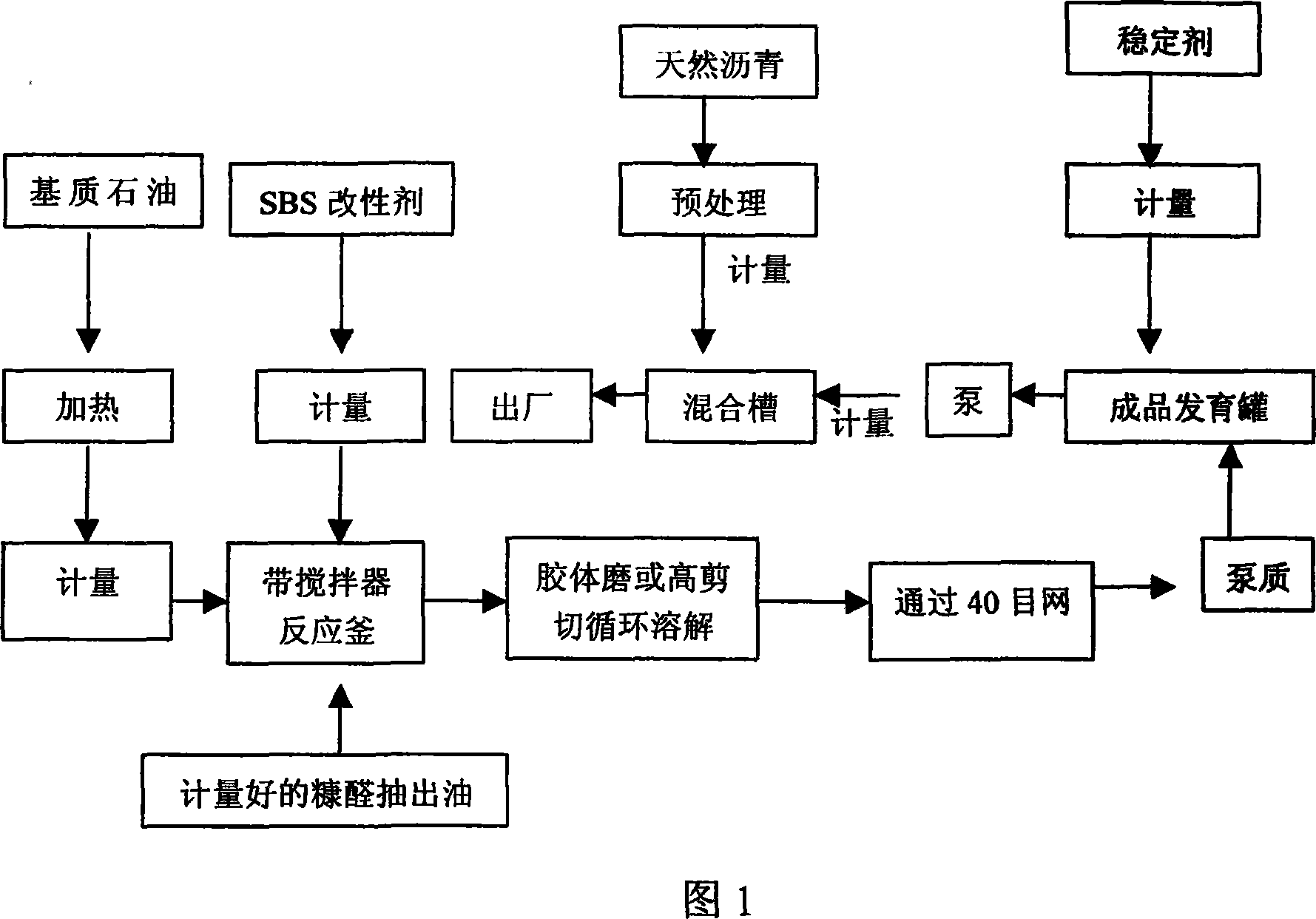

[0023] Referring to Fig. 1, the production method of composite modified asphalt of the present invention, it mainly comprises following processing steps:

[0024] Step 1. Add a certain amount of base petroleum asphalt into the stirring reactor, and form a closed circuit system with colloid mill and agitator. When the temperature of base petroleum asphalt is heated to 180°C±5°C, add SBS modifier, furfural Add the extracted oil and furfural extracted oil into the stirring reaction kettle, and add the SBS modifier while shearing, so that the SBS modifier is fully dissolved, and the mixed solution I is obtained.

[0025] Step 2, when the mixed solution I swells and can pass through the 40 mesh, pump the swollen mixed solution I into the finished product development tank.

[0026] Step 3: Keep the finished product development tank at a temperature of 175°C±5°C, add a stabilizer while stirring, and stir for 2 hours±0.5 hours after adding the stabilizer to obtain a mixed solution II....

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com