Organic solvent-free RTV anti-pollution flashover coating and preparation method thereof

A technology of antifouling flashover coatings and organic solvents, applied in antifouling/underwater coatings, biocide-containing paints, coatings, etc., can solve the volatile odor of reactive diluents, environmental and human hazards, construction environmental pollution, etc. problems, to achieve good operability, reduce damage, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

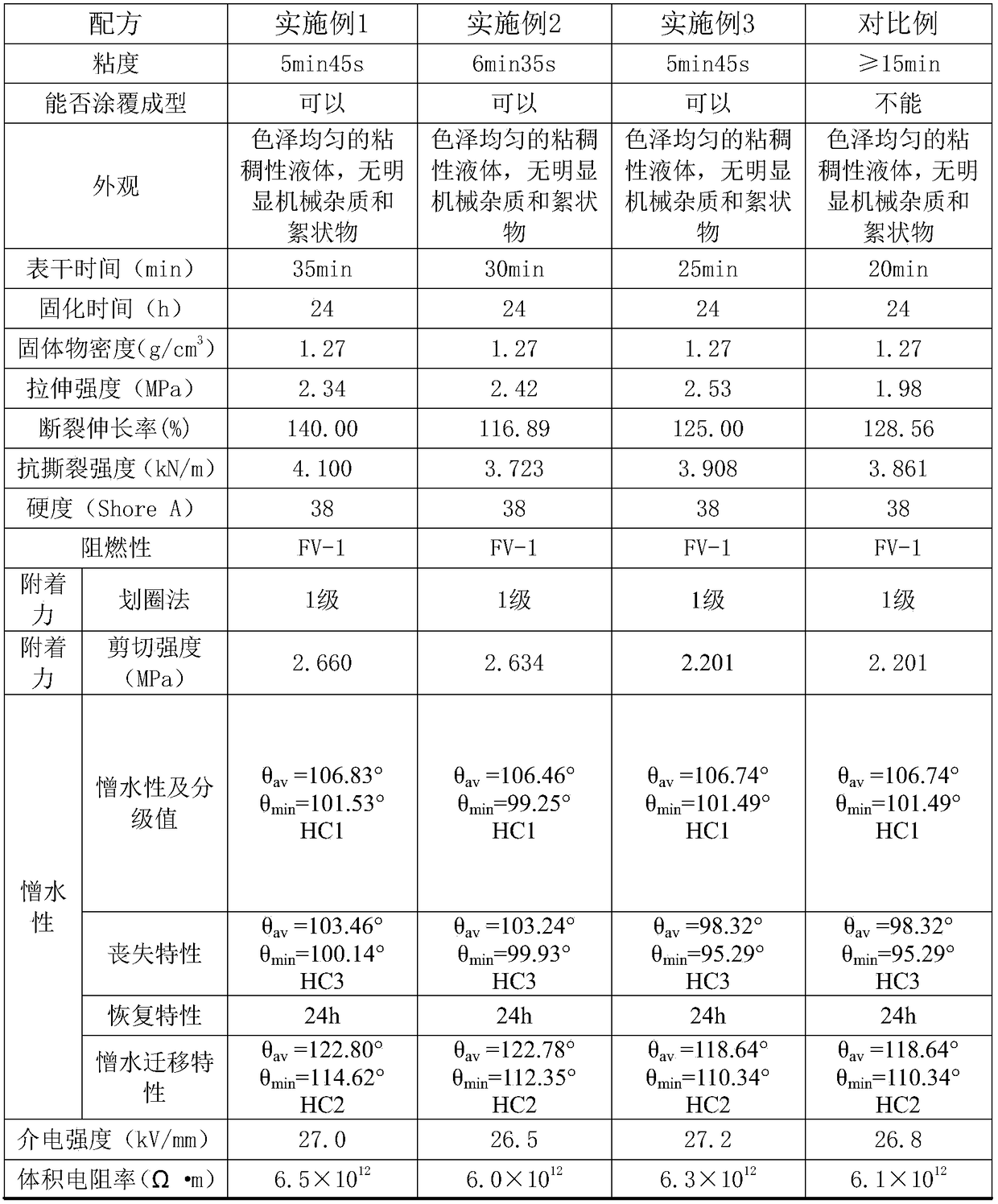

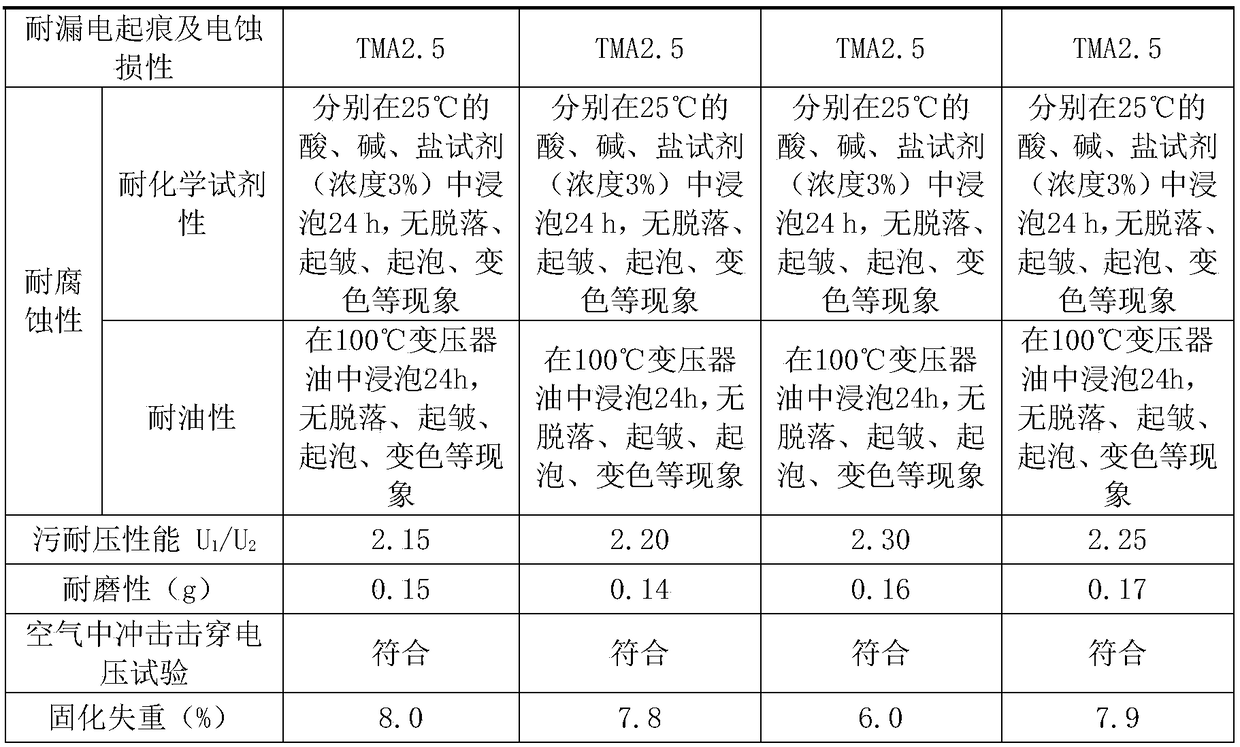

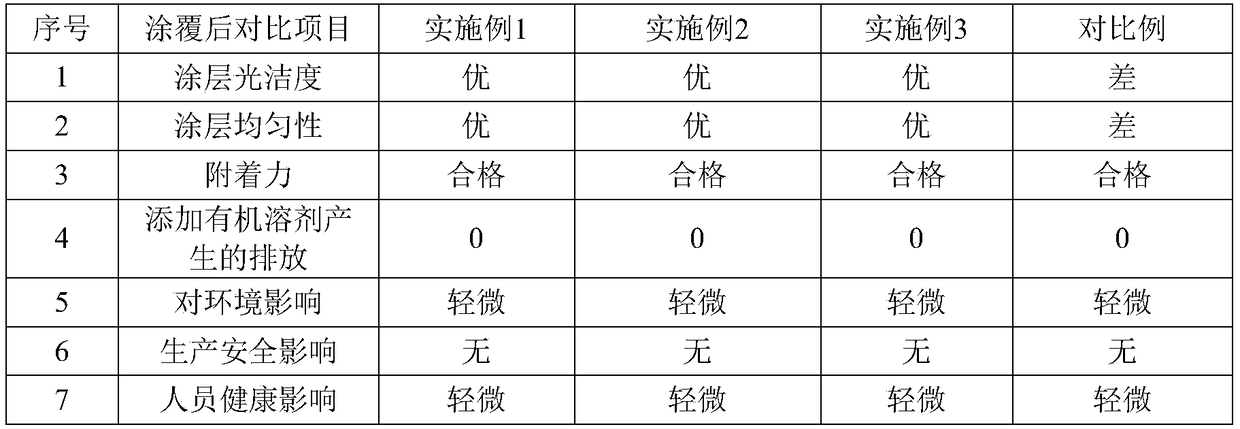

Examples

Embodiment 1

[0035] Weigh 40 parts of hydroxyl-terminated polydimethylsiloxane with a viscosity of 500mpa.s; 5 parts of dimethyl silicone oil with a viscosity of 10mpa.s; 10 parts of MQ resin with methyl silicone chain as the main chain; 30 parts of alumina; 5 parts of methyl tributylketoxime silane; 5 parts of dimethyl dibutylketoxime silane; 0.5 parts of γ-aminopropyl triethoxysilane; 0.5 parts of tin compound; 4 parts of iron oxide red share.

[0036]Mix 40 parts of hydroxyl-terminated polydimethylsiloxane with a viscosity of 500mpa.s, 5 parts of dimethyl silicone oil with a viscosity of 10mpa.s, 10 parts of MQ resin with methylsiloxane as the main chain, 30 parts Put the aluminum hydroxide into the biaxial kneader, stir and knead for 20 minutes to obtain the base rubber; put the base rubber into the three-roll machine and grind it twice; put the ground base rubber into the biaxial kneader again, heat up and stir , keep the set temperature at 100°C and vacuum degree -0.08Mpa and vacuum...

Embodiment 2

[0038] Weighing 35 parts of a mixture of hydroxyl-terminated polydimethylsiloxane and alkoxy polydimethylsiloxane with a viscosity of 1500mpa.s; 10 parts of dimethyl silicone oil with a viscosity of 250mpa.s; 15 parts of MDQ resin with oxygen chain as the main chain; 20 parts of aluminum hydroxide and magnesium hydroxide mixture; 1 part of methyltriethoxysilane; 10 parts of methylpropyldimethoxysilane; 5 parts of a mixture of triethoxysilane, γ-glycidyl etheroxypropyl trimethoxysilane, N-(β-aminoethyl)-γ-aminopropyl trimethoxysilane; 0.5 parts of titanium compound catalyst; 3.5 parts of mixture of green and carbon black.

[0039] Mix 35 parts of a mixture of hydroxyl-terminated polydimethylsiloxane and alkoxy polydimethylsiloxane with a viscosity of 1500mpa.s, 10 parts of dimethicone oil with a viscosity of 250mpa.s, 15 parts of methyl Put the MDQ resin with silicone chain link as the main chain, 20 parts of aluminum hydroxide and magnesium hydroxide mixture into the biaxial ...

Embodiment 3

[0041] Weigh 50 parts of alkoxy polydimethylsiloxane with a viscosity of 3000mpa.s; 8 parts of dimethyl silicone oil with a viscosity of 500mpa.s; 5 parts of MTQ resin with methylphenylsiloxane chain as the main chain 20 parts of magnesium hydroxide; 8 parts of methyltrimethoxysilane; 2 parts of methylpropyldimethoxysilane; 4 parts of γ-glycidyl etheroxypropyl trimethoxysilane; 1 part of titanium compound; Yellow 2 parts.

[0042] Mix 50 parts of alkoxypolydimethylsiloxane with a viscosity of 3000mpa.s, 8 parts of dimethyl silicone oil with a viscosity of 500mpa.s, and 5 parts of MTQ resin with methylphenylsiloxane as the main chain , Put 20 parts of magnesium hydroxide into the material tank, and stir at high speed with a high-speed mixer for 50 minutes to obtain the base rubber; put the base rubber into the sand mill and sand it for 3 times; put the sanded base rubber into the double In the shaft kneader, heat up and stir, keep the set temperature at 150°C, and vacuum-dry a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com